Valve element structure controlling glue spraying

A technology of spraying glue and valve core, which is applied in the direction of valve device, book binding, adhesive used for binding, etc., can solve the problems of affecting the quality of glue packaging, not closing tightly enough, hindering the cover packaging, etc., so as to improve the quality of glue packaging. , The effect of tight shut-off and shortening of switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

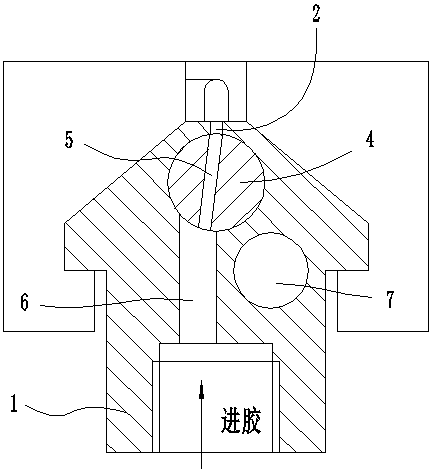

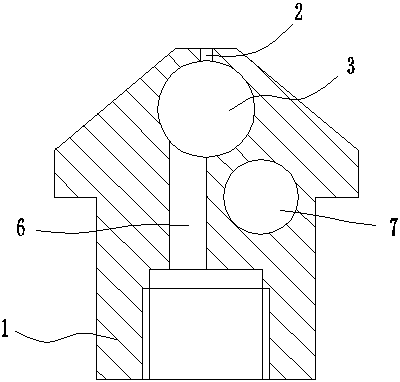

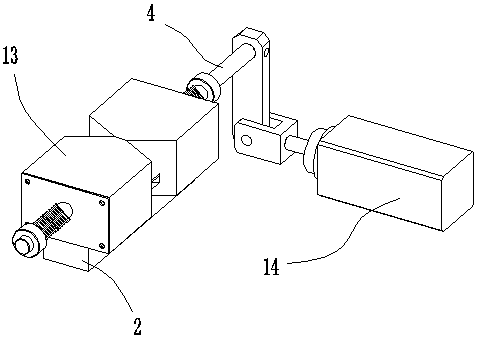

[0025] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 5 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0026] A valve core structure for controlling glue spraying, comprising a nozzle body 1 and a glue spraying straight seam 2 set on the top of the nozzle body 1, a cylindrical through hole 3 is provided at the lower end of the glue spraying straight seam 2, and the A shaft-type spool 4 is pierced through the cylindrical through-hole 3 , and a glue-through straight seam 5 is provided on the shaft-type spool 4 , and a glue-feeding groove 6 is provided below the middle part of the cylindrical through-hole 3 . The glue-through straight seam 5 is arranged along the axis and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com