Blockage-free water inlet pipe of sewage pump

A sewage pump, non-clogging technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of single anti-clogging function and poor sewage pump effect, and achieve the effects of diverse functions, avoiding clogging and high sewage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

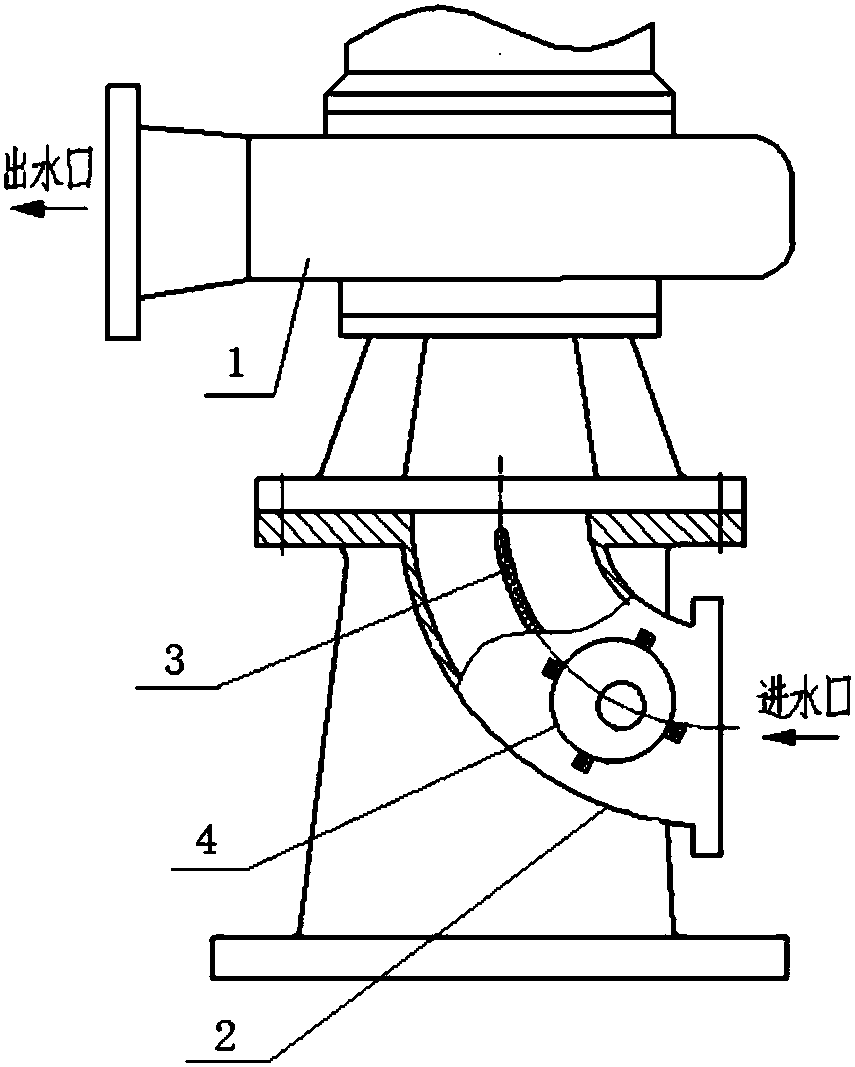

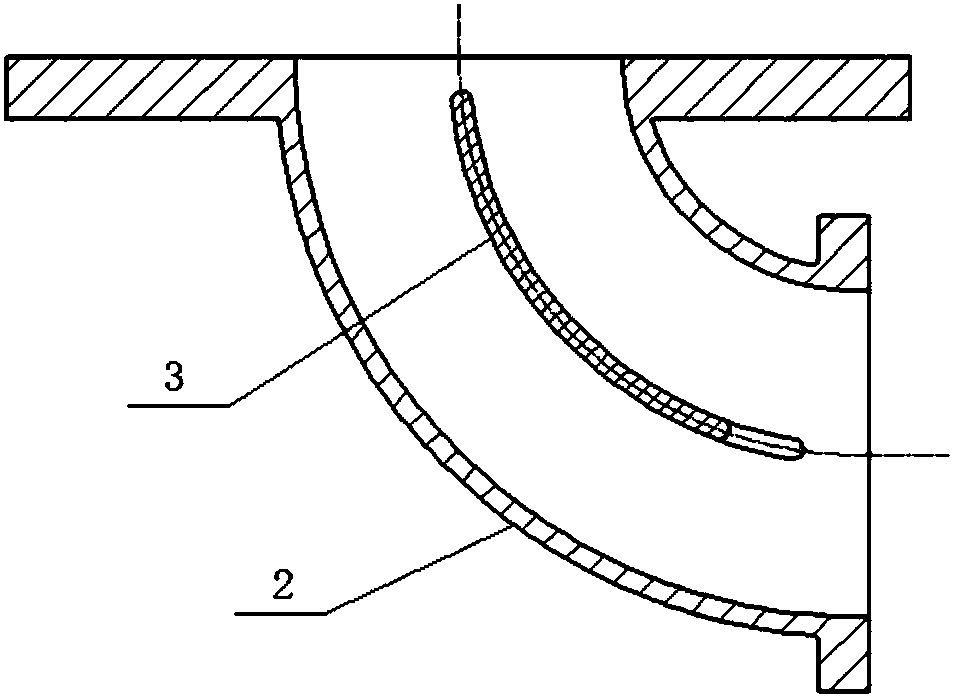

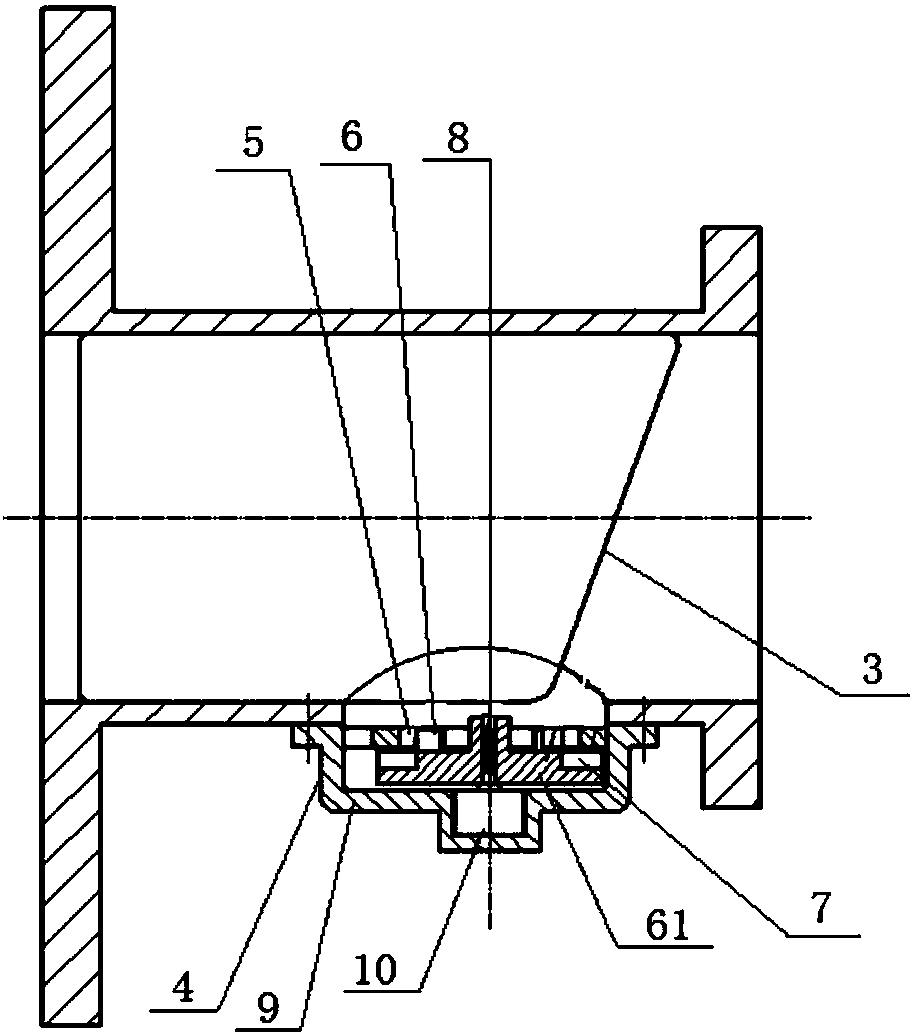

[0026] see Figure 1 to Figure 7 , the non-blocking water inlet pipe of the sewage pump according to an embodiment of the present invention includes a water inlet elbow 2 connected to the water inlet of the sewage pump 1, and a water inlet elbow 2 is arranged along the inner wall of the flow channel to divide it into upper and lower two. The diversion rib 3 of the flow channel, the inlet side of the diversion rib 3 is a hypotenuse, the angle between the hypotenuse and the busbar of the water inlet elbow 2 is 70°, and the side of the water inlet elbow 2 is equipped with a filter that can suck and shred dirt. The circular groove convex shape cutting chamber 4.

[0027] The cutting chamber 4 is provided with a static knife 5, a moving knife 6, a rotating shaft 8, a centrifugal blade 7, a cutting chamber cover plate 9 and a motor 10, and the static knife 5 includes a stationary annular flat plate 51, which is evenly set on the periphery of the annular flat plate 51. 4-8 arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com