Wharf ship boarding ladder capable of being adjusted all-directionally and automatically

An automatic adjustment and all-round technology, applied in the field of dock boarding ladders, can solve the problems that cannot completely eliminate the irregular swing of the ship, increase the workload of welding and dismantling, and affect the service life of boarding ladders, etc., so as to achieve small space occupation, Easy to set up and dismantle, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

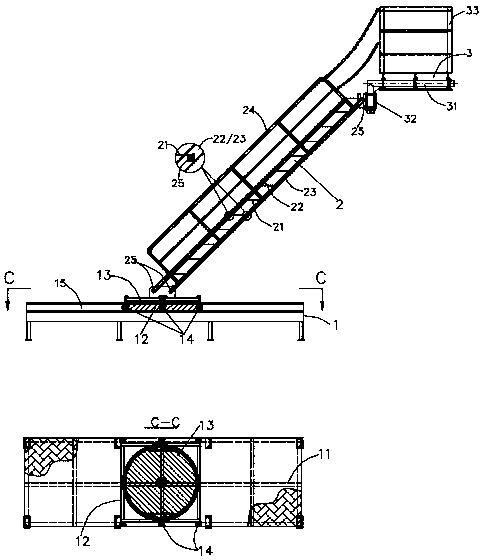

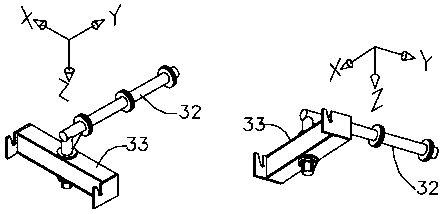

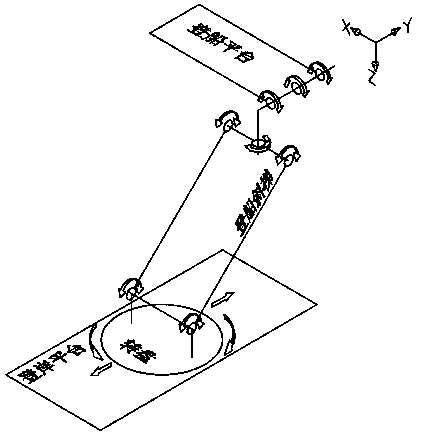

[0031] refer to Figure 1-5 , a dock boarding ladder that can be adjusted automatically in all directions, including a landing platform 1, a boarding inclined ladder 2 and a boarding platform 3, the top of the landing platform 1 is provided with a landing support platform 11, and the landing support platform 11 Roller bearing track 15 is arranged on the straight line on the upper two sides, and movable platform 12 is arranged in the roller bearing track 15, and roller bearing 14 is arranged on both sides of movable platform 12, so that movable platform 12 can only slide back and forth along the roller bearing track 15 on the landing support platform 11 And do not bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com