Method for preparing edible fungus cultivated species with corn cobs being main material

A technology of corncobs and edible fungi, which is applied in cultivation, plant cultivation, mushroom cultivation, etc., can solve the problems of poor aging resistance of strains, slow growth of mycelium, and narrow source channels, so as to reduce raw material costs and increase growth speed , The effect of reasonable ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

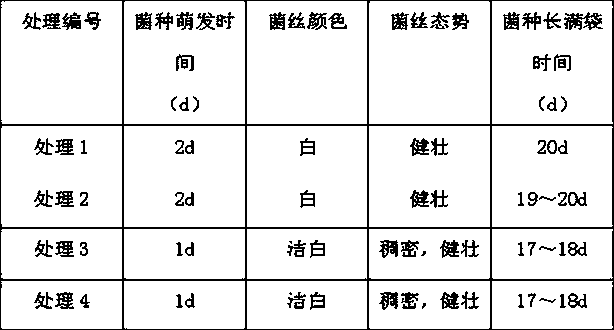

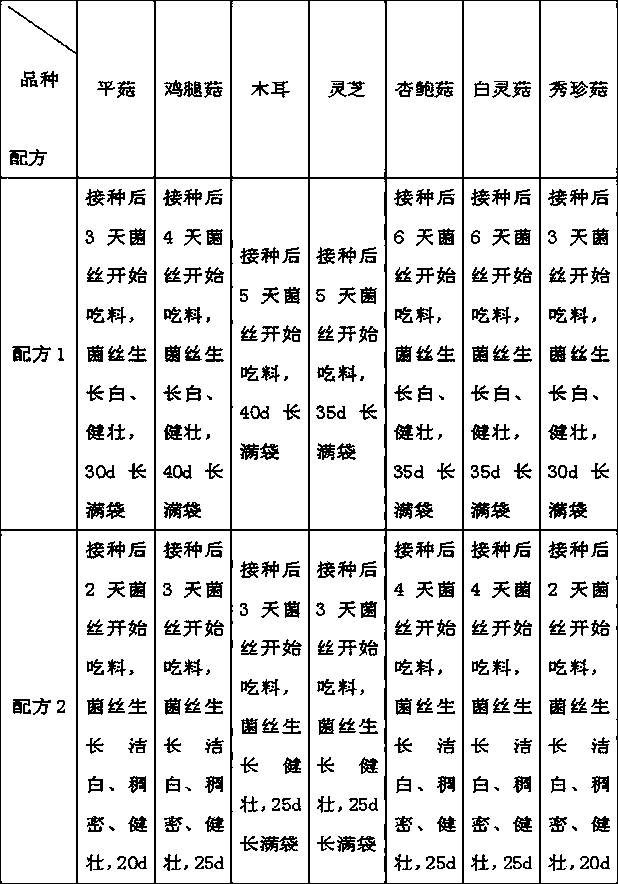

Embodiment 1

[0019] Embodiment 1: A method for making edible fungus cultivars with corn cobs as the main ingredient, comprising the following preparation steps: Raw material preparation: selecting soybean-sized, dry, mildew-free corn cobs, and the corn cobs in step 1) Pre-wet 10 hours before use, the water holding capacity ratio of corncobs is 3.5:1, with no dry parts in the center of the granules as the standard; choose fresh, dry, loose granules, normal color, no mildew, no pests, no clumping, no peculiar smell, Cottonseed hulls without impurities; choose dry, loose grains of millet bran, choose dry, non-agglomerated bran, soybean meal, lime powder, gypsum powder, potassium dihydrogen phosphate and fulvic acid raw powder; cultivation raw material formula: corn Core 54.2%, cottonseed hull 10%, bran 10%, millet bran 5%, soybean meal 3%, lime powder 1%, gypsum powder 1%, potassium dihydrogen phosphate 0.3%, fulvic acid raw powder 0.2%; : Put the raw materials other than the original fulvic ...

Embodiment 2

[0020] Embodiment 2: A method for making edible fungus cultivars with corncobs as the main ingredient, comprising the following preparation steps: Raw material preparation: choose corncobs with the size of soybeans, dry and mildew-free, and the corncobs in the step 1) Pre-wet for 10-12 hours before use, the water holding capacity ratio of corncobs is 3.7:1, with no dry parts in the center of the granules as the standard; choose fresh, dry, loose granules, normal color, no mildew, no pests, no clumping, no rot Cottonseed hulls with peculiar smell and no impurities; use dry, loose grains of millet bran, use dry, non-agglomerated bran, soybean meal, lime powder, gypsum powder, potassium dihydrogen phosphate and fulvic acid raw powder; cultivation raw material formula : Corncob 60%, cottonseed hull 13%, bran 13%, millet bran 7%, soybean meal 45%, lime powder 1%, gypsum powder 1%, potassium dihydrogen phosphate 0.4%, fulvic acid raw powder 0.26%. Mixing material: Put the raw materi...

Embodiment 3

[0021]Embodiment 3: A method for making edible fungus cultivars with corncobs as the main ingredient, including the following preparation steps: Raw material preparation: choose corncobs with the size of soybeans, dry and mildew-free, and the corncobs in the step 1) Pre-wet for 12 hours before use, the water holding ratio of corncobs is 3.8:1, with no dry part in the center of the granules as the standard; choose fresh, dry, loose granules, normal color, no mildew, no insect damage, no agglomeration, no peculiar smell, Cottonseed hulls without impurities; choose dry, loose grains of millet bran, choose dry, non-agglomerated bran, soybean meal, lime powder, gypsum powder, potassium dihydrogen phosphate and fulvic acid raw powder; cultivation raw material formula: corn Core 69.5%, cottonseed hull 15%, bran 15%, millet bran 8%, soybean meal 5%, lime powder 1%, gypsum powder 1%, potassium dihydrogen phosphate 0.5%, fulvic acid powder 0.3%; : Put the raw materials other than the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com