Cement powder concentrator power assembly and low-speed high-torque amorphous permanent magnet motor thereof

A low-speed, high-torque, permanent magnet motor technology, applied in the manufacture of motor generators, electromechanical devices, magnetic circuits, etc., can solve the problems of large stator and rotor iron loss, temperature rise of permanent magnet motors, magnetic flux leakage, etc., to achieve The effect of intelligence, reducing magnetic flux leakage, and reducing the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

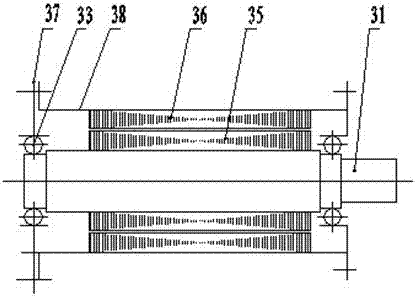

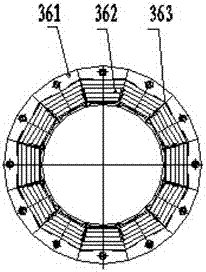

[0021] Such as figure 1 As shown, the power assembly of the cement powder separator of the present invention includes a mounting seat 1 located at the top of the powder separator 2, and a low-speed high-torque amorphous permanent magnet motor 3 is vertically installed on the top of the powder separator through the mounting seat 1 , the output shaft 31 of the low-speed high-torque amorphous permanent magnet motor 3 directly drives the fan of the powder separator 2, and the frequency conversion speed control cabinet 4 is connected with the low-speed high-torque amorphous permanent magnet motor 3 . The end cover of the low-speed high-torque amorphous permanent magnet motor 3 is provided with a main outlet box 34 and an auxiliary outlet box 32, and an outlet wire structure is provided at the end to facilitate vertical connection. The original drive assembly of the powder separator 2 is a three-phase asynchronous motor acceleration and deceleration structure, which is now improved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com