Crosslinked polyethylene insulated power cable

A cross-linked polyethylene and power cable technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of damaging the internal structure of the core, endangering personal and public property safety, etc., to improve heat resistance and fire resistance, and protect personal safety. and public property safety, the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

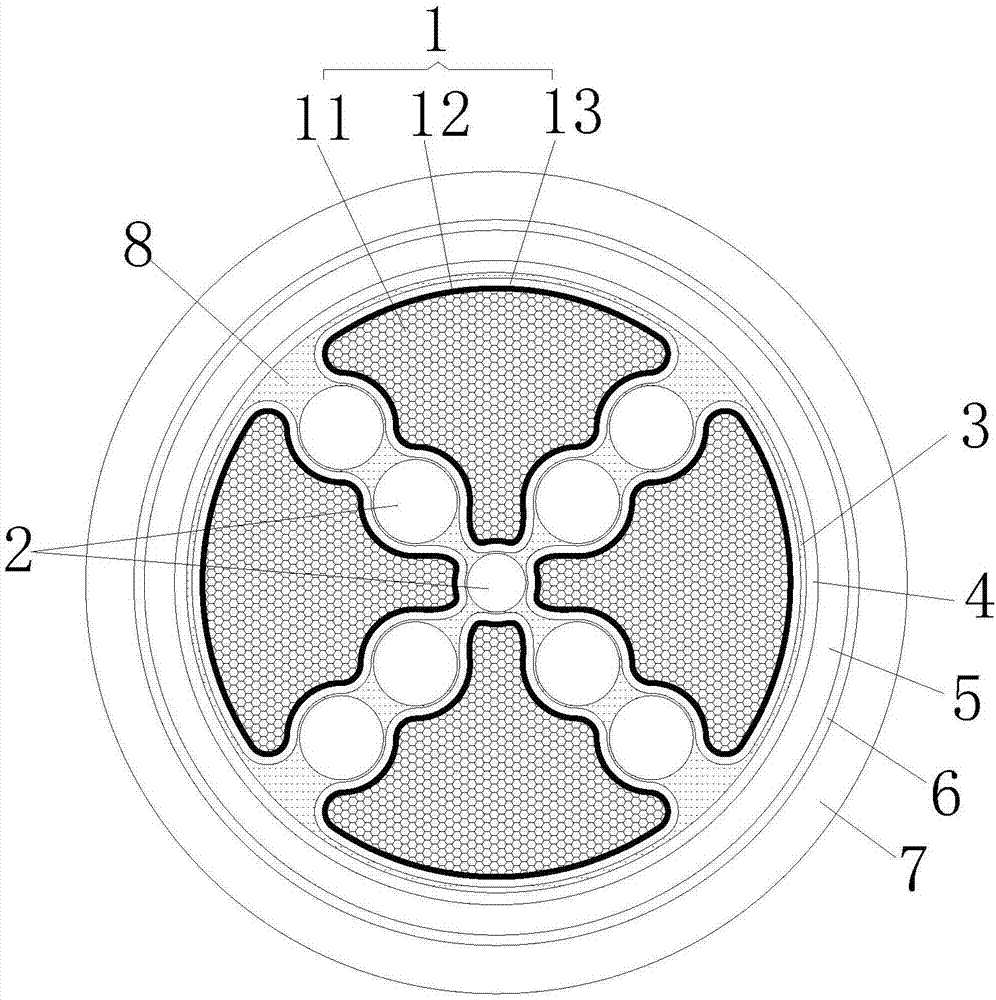

[0017] like figure 1 As shown, a cross-linked polyethylene insulated power cable includes several fan-shaped cores 1 evenly spaced along the circumferential direction, between adjacent fan-shaped cores 1, and at the center where several fan-shaped cores 1 are distributed. There is a filling rod 2, the filling rod 3 is made of rubber, and the outside of the fan-shaped core 1 is covered with an inner lining layer 3, an outer refractory layer 4, a galvanized steel wire armor 5, and a tape layer from the inside to the outside. 6. Outer sheath 7 , a filler 8 is provided between the inner lining layer 3 and the fan-shaped core 1 .

[0018] Based on the above, it can be seen that the use of the filling rod 2 can form a good buffer and shock absorbing layer between the adjacent fan-shaped core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com