Continuous production method and device for purified-cotton bleached non-woven fabrics

A technology of production device and production method, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, non-woven fabrics, etc., can solve the problems of high labor intensity, long production time, process discontinuity, etc. The effect of labor intensity, improving product quality and improving production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

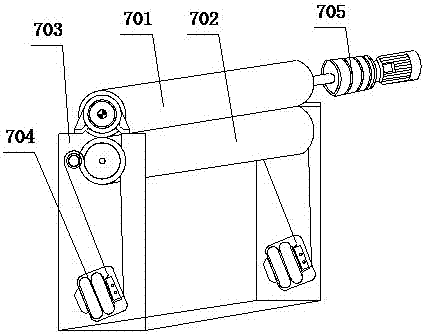

[0032] see Picture 1-1 0. The present invention relates to a continuous production method and device for bleached pure cotton non-woven fabrics, comprising:

[0033] Step 1. Raw cotton opening: before opening, the impurities and foreign fibers in the cotton are detected, and the raw cotton is sucked into the cotton box by the fan for rough opening and fine opening;

[0034] Step 2, carding: the cotton after opening is carded by a carding machine, so that the cotton fibers are in a single fiber state, and the short fibers in the cotton are removed, and then mixed and carded, and finally carded into a fiber web in which the cotton fibers are arranged in the warp direction. The carding machine is equipped with a dust removal system;

[0035] Step 3, cross-lapping: the fiber web in step 2 is reciprocally laminated into the required thick fiber web through the web-laying machine, and the fibers are cross-laid in the warp and weft directions as much as possible to increase the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com