Method for positioning for plate blank distribution according to steel type and finished product specification

A slab and steel type technology, which is applied in the field of slab cloth positioning according to the steel type and finished product specifications, can solve problems such as unstable slab rolling, large temperature drop at the tail, and slab deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

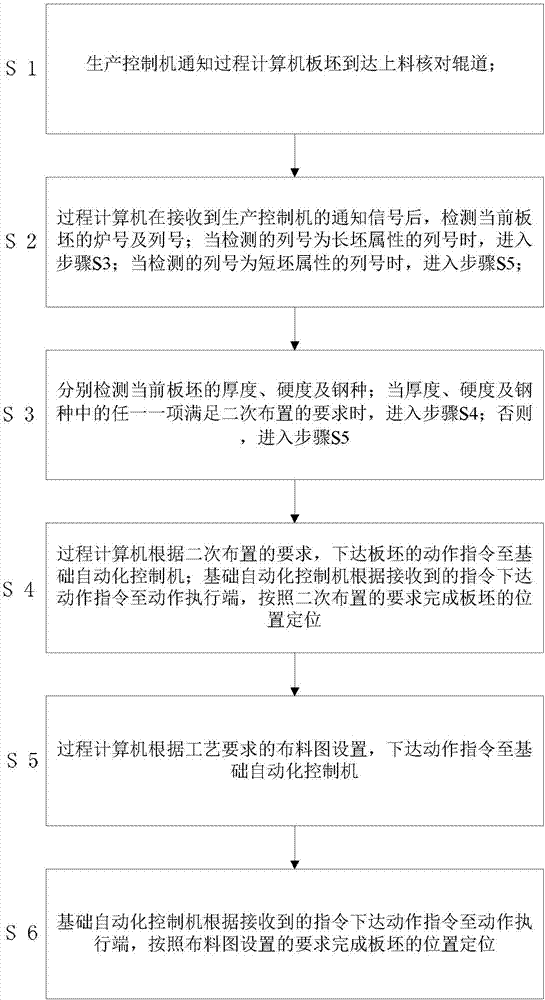

[0054] In order to realize that the slab can be positioned according to information such as steel type, hardness group, and finished product thickness, the specific steps are as follows:

[0055] 1. The slab reaches the feeding check roller table;

[0056] 2. The operator assigns the furnace number and column number of the slab through the L2 computer;

[0057] 3. The L2 computer judges the process requirements of the slab based on information such as the steel type, hardness group, and finished product thickness of the slab to be checked.

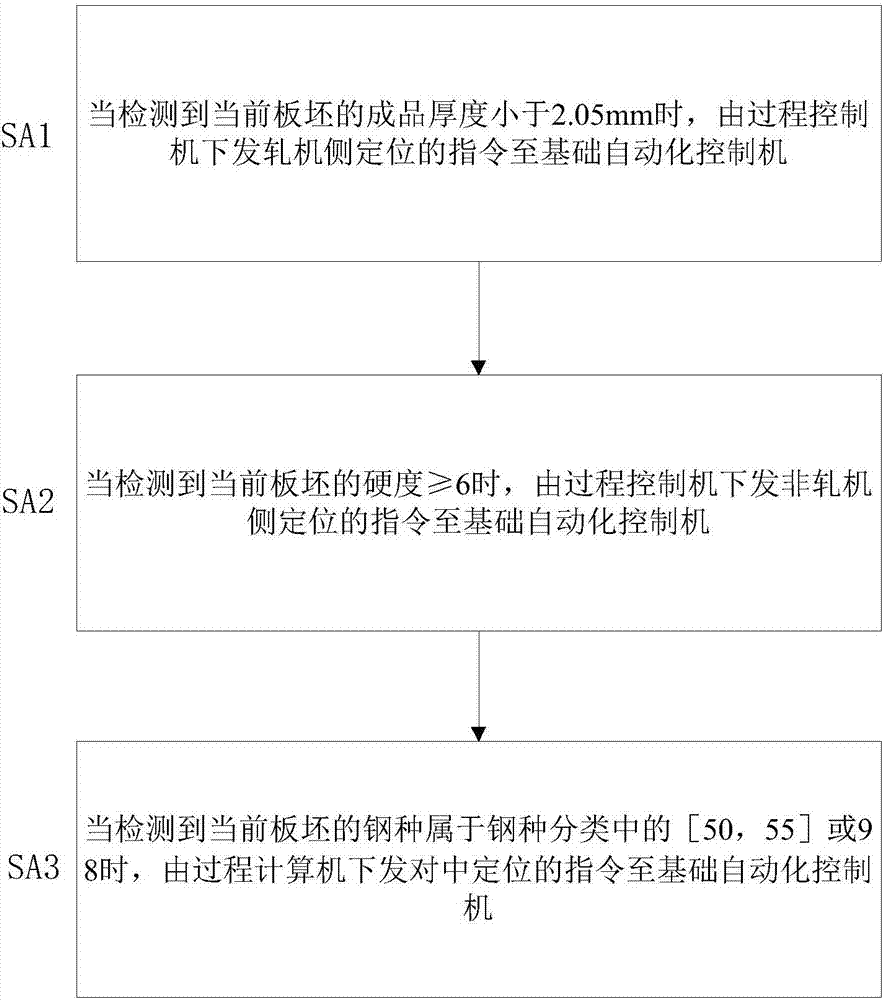

[0058] (3-1.) Steel types that require the end of the slab to be close to the side of the rolling mill are mainly used for the positioning of thin gauge products. In order to ensure the rolling stability, the temperature of the end of the slab from different heating furnaces and the same heating furnace must be consistent . The judgment method is as follows:

[0059] a. All finished products with a thickness less than 2.05mm shall be cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com