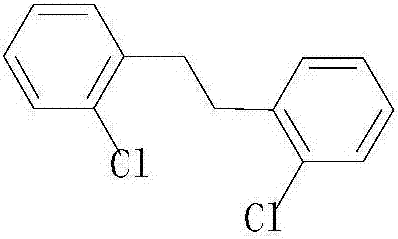

Preparation method of 2-chlorobenzyl chloride Grignard reagent

A technology of benzyl chloride Grignard and methylmagnesium chloride Grignard is applied in the synthesis field of 2-chlorobenzyl chloride Grignard reagent, can solve problems such as troublesome handling, poor safety, low boiling point, etc., achieves easy clean production and reduces impurities , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

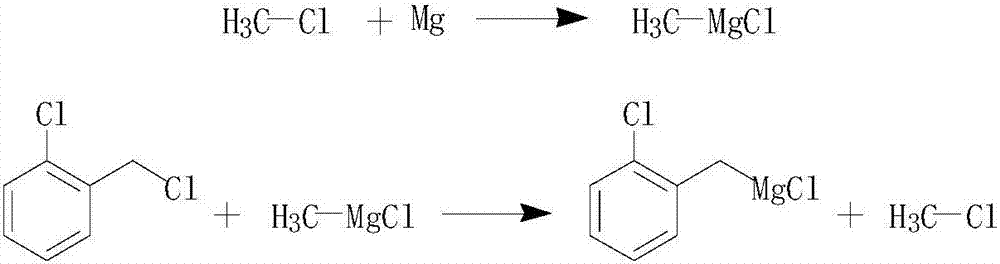

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of 2-chlorobenzyl chloride Grignard reagent comprises the following steps:

[0031] a. After replacing the 3000L clean Grignard reactor with nitrogen, under the protection of nitrogen, add 200kg of tetrahydrofuran with a water content of less than 100ppm and 60kg of magnesium chips. The reaction system was closed, and 0.5 kg of methyl bromide was added to initiate the reaction. 135.9kg of methyl chloride was introduced at 65-70°C, and 1600kg of tetrahydrofuran with a water content of less than 100ppm was added at a constant speed. After the addition was complete, it was stirred at 70°C for 1 hour. Keep the temperature of the methylmagnesium chloride Grignard reactor at 40°C-50°C.

[0032] b. Catalyst Cl 4 CuLi 2 Preparation: under the protection of nitrogen, 85g of anhydrous lithium chloride and 135g of anhydrous copper chloride were dissolved in 1500g of tetrahydrofuran with a water content of less than 100ppm.

[0033] c. At the same time, ...

Embodiment 2

[0035] The preparation technology of 2-chlorobenzyl chloride Grignard reagent comprises the following steps:

[0036] a. After replacing the 3000L clean Grignard reactor with nitrogen, under the protection of nitrogen, add 200kg of tetrahydrofuran with a water content of less than 100ppm and 60kg of magnesium chips. The reaction system was closed, and 0.5 kg of methyl bromide was added to initiate the reaction. 135.9kg of methyl chloride was introduced at 65-70°C, and 1600kg of tetrahydrofuran with a water content of less than 100ppm was added at a constant speed. After the addition was complete, it was stirred at 70°C for 1 hour. Keep the temperature of the methylmagnesium chloride Grignard reactor at 40°C-50°C.

[0037] b. Catalyst Cl 4 CuLi 2 Preparation: Dissolve 85g of anhydrous lithium chloride and 135g of anhydrous copper chloride in 1500g of tetrahydrofuran with a water content of less than 100ppm.

[0038] c. At the same time, after nitrogen replacement in anothe...

Embodiment 3

[0040] The preparation technology of 2-chlorobenzyl chloride Grignard reagent comprises the following steps:

[0041] a. After replacing the 3000L clean Grignard reactor with nitrogen, under the protection of nitrogen, add 200kg of tetrahydrofuran with a water content of less than 100ppm and 60kg of magnesium chips. The reaction system was closed, and 0.5 kg of methyl bromide was added to initiate the reaction. 135.9kg of methyl chloride was introduced at 65-70°C, and 1600kg of tetrahydrofuran with a water content of less than 100ppm was added at a constant speed. After the addition was complete, it was stirred at 70°C for 1 hour. Keep the temperature of the methylmagnesium chloride Grignard reactor at 40°C-50°C.

[0042] b. Catalyst Cl 4 CuLi 2 Preparation: Under the protection of nitrogen, 85g of anhydrous lithium chloride and 135g of anhydrous copper chloride were dissolved in 1500g of tetrahydrofuran with a water content of less than 100ppm.

[0043] c. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com