Vision sensing device for welding seam tracking

A visual sensor, visual sensor technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor flexibility, single function, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

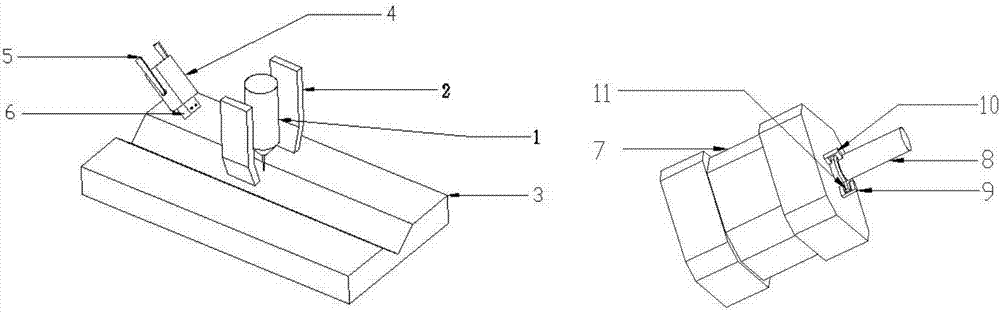

[0026] Example 1, such as figure 1 As shown, the first step: before the welding starts, the visual sensor 4 directly takes pictures of the workpiece 3 without adding a light-reducing filter, and the image processing is used to identify and guide the welding seam and the starting position of the welding And carry out the trajectory planning of the front distance welding torch for rough tracking.

[0027] Step 2: Swing the swing arm 5 to align the vision sensor 4 with the welding torch, and the upper position of the slider 1 (22) is ready to acquire images during welding in real time.

[0028] Step 3: After starting welding, process the image collected by the visual sensor to obtain the deviation value between the center of the weld seam and the center of the molten pool, and then compare it with the left and right deviation value obtained by the magnetron arc sensor. When the threshold value is higher than the threshold value, the deviation information obtained by the visual s...

Embodiment 2

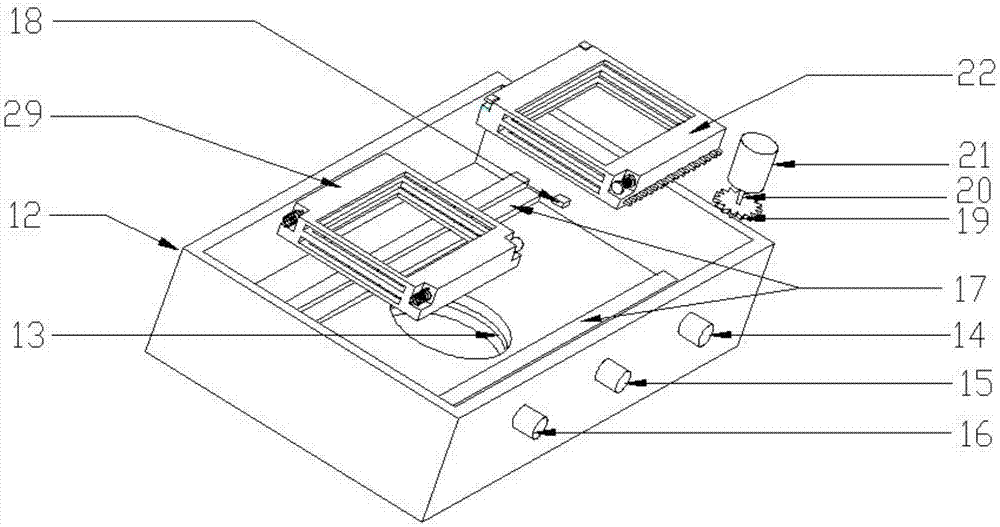

[0031] Example 2, such as Figure 2-Figure 5 , the slider 1 (22) and the slider 2 (29) move on the slide rail 17, and the slider 1 (22) drives the rotating gear 25 meshed with the transmission gear 19 through the transmission motor 21 to rotate and slide , the motion state of the slider 2 (29) is jointly determined by the spring 34 and the electromagnet 26 on the slider 1 (22).

[0032] Described transmission motor 21 adopts photoelectric switch to control the on-off of relay to control the positive and negative rotation and start-stop of transmission motor, as Figure 4 , 5 . Among them, the relay normally closed normally open contact SB 2 Controlled by the photoelectric switch 1 (9), when the shading plate 1 (11) on the swing motor 7 rotates to the photoelectric switch 1 (9) on it, the normally open contact SB 2 closed, normally closed contact SB 2 disconnected, the transmission motor 21 rotates forward, and at the same time Figure 5 The light-emitting diode in the mi...

Embodiment 3

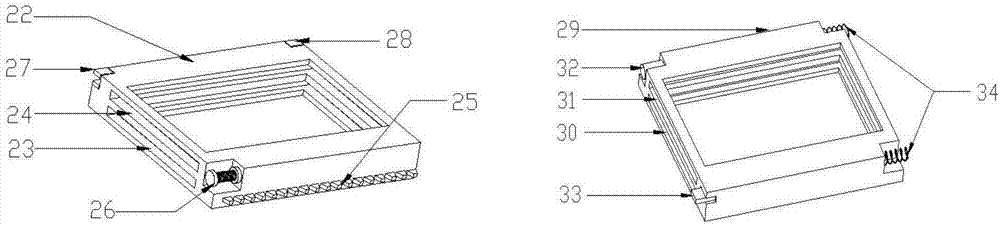

[0033] Example 3, such as Figure 6 As shown, the electromagnet 26 uses the photoelectric switch 2 (10) and the photoelectric switch 3 (27) to control its on-off through the SR latch. When the light-shielding sheet 3 (33) entered the photoelectric switch 3 (27), the S terminal was set to 1 in the SR latch, and the R terminal was still 0. At this time, Q was converted to Q=1, and the electromagnet 26 was energized to absorb the iron block 32 Drive slide block 2 (29) common motion, simultaneously Figure 6 Medium LED D 2 Conduction, indicator light 3 (16) is bright. When the swing motor 7 starts to move, it drives the shading plate 1 (11) on the rotating shaft 1 (8) to rotate to the photoelectric switch 2 (10). At this moment, the R terminal is set to 1, the S terminal is 0, Q is converted to Q=0, and the electromagnetic Iron power failure, slide block 2 (29) resets under the effect of spring 34, and indicator light 3 (16) goes out simultaneously. Make full use of the hold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com