Pressure-casting mold for anti-theft lock cases

A technology of die-casting molds and anti-theft locks, which is applied in the field of metal die-casting molds, can solve problems such as low efficiency, unreasonable design of die-casting molds, and poor quality of anti-theft lock shells, and achieve high efficiency, ensure molding quality, precision and rapid prototyping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

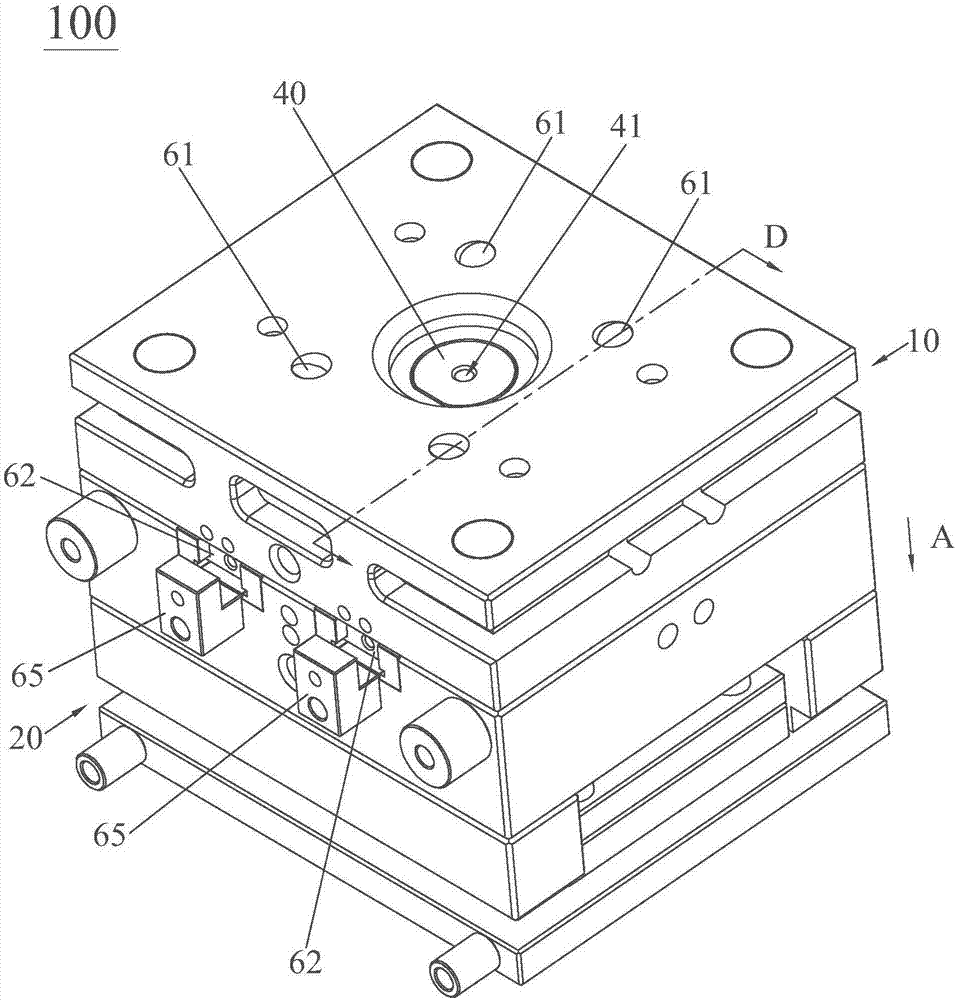

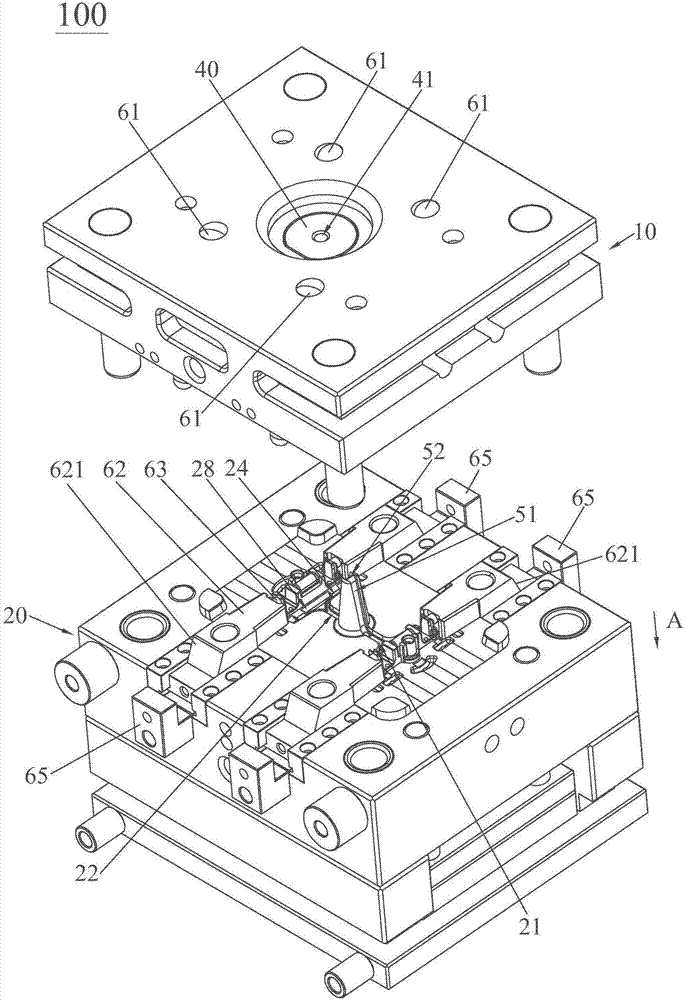

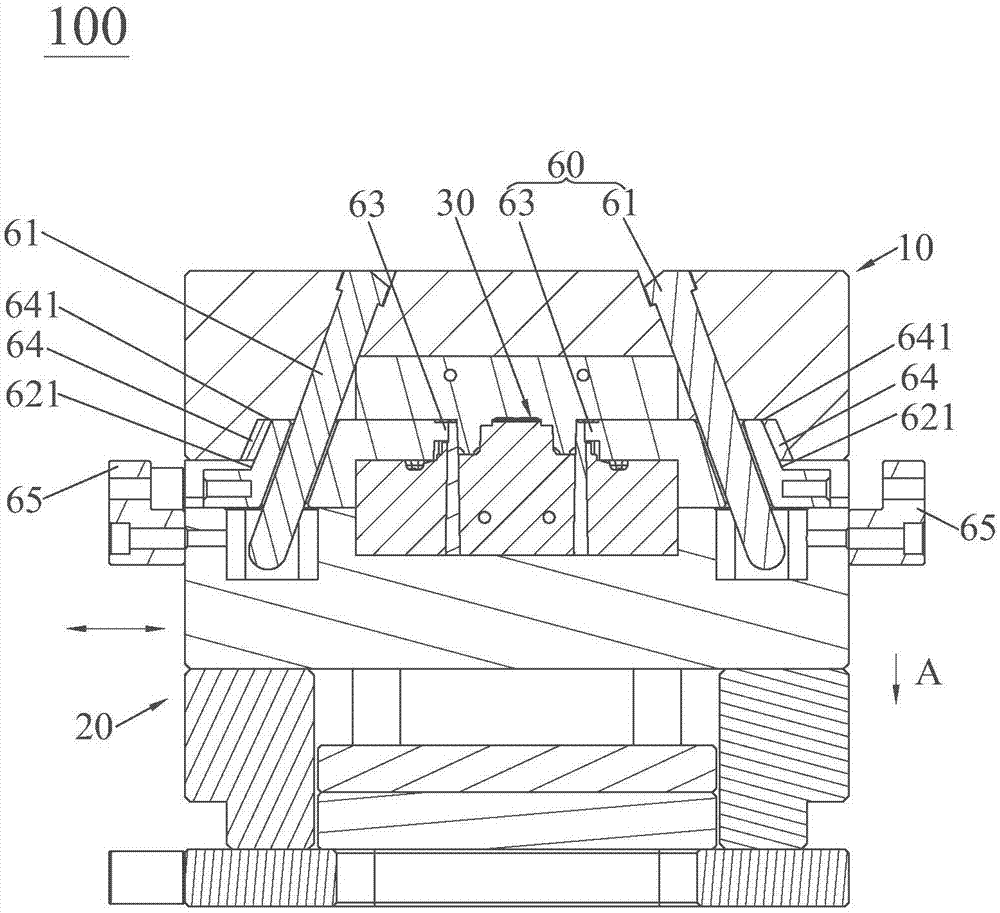

[0023] see Figure 1 to Figure 3 , the die-casting mold 100 for the anti-theft lock case of the present invention is used for one-time die-casting of two anti-theft lock cases 200 (see Figure 8 ), including a pouring nozzle 40, a splitter cone 50, a side core pulling mechanism 60, and a fixed mold 10 and a movable mold 20 that cooperate with each other. After the fixed mold 10 and the movable mold 20 are closed, they jointly enclose two spaced apart arrangements such as one in front of the other. image 3 As shown in the molding cavity 30, each molding cavity 30 corresponds to two side core-pulling mechanisms 60 located on the left and right sides of the molding cavity 30, and the left and right side pulling of a molding cavity 30 is realized by the two side core-pulling mechanisms 60 the goal of. The pouring nozzle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com