Die-casting formation mold for annular shell

A die-casting and ring-shaped technology, which is applied in the field of die-casting molding molds for ring-shaped shells, can solve problems such as unreasonable design of die-casting molds and poor quality of ring-shaped shells, so as to achieve smooth transportation, ensure molding quality, and prevent scurrying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

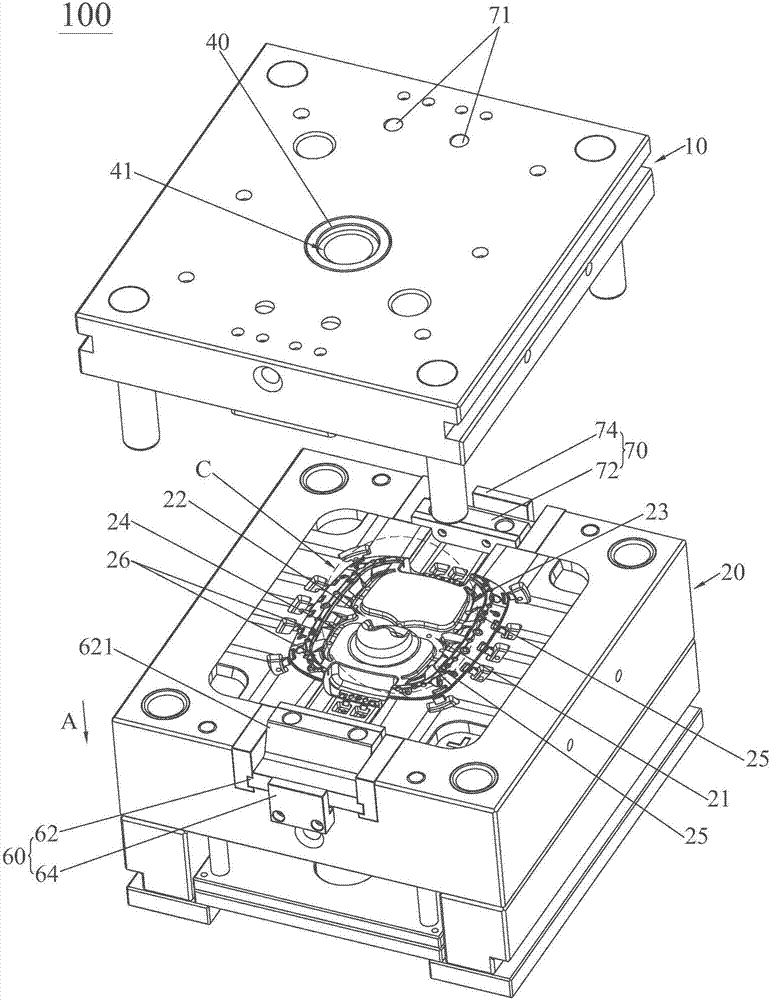

[0021] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

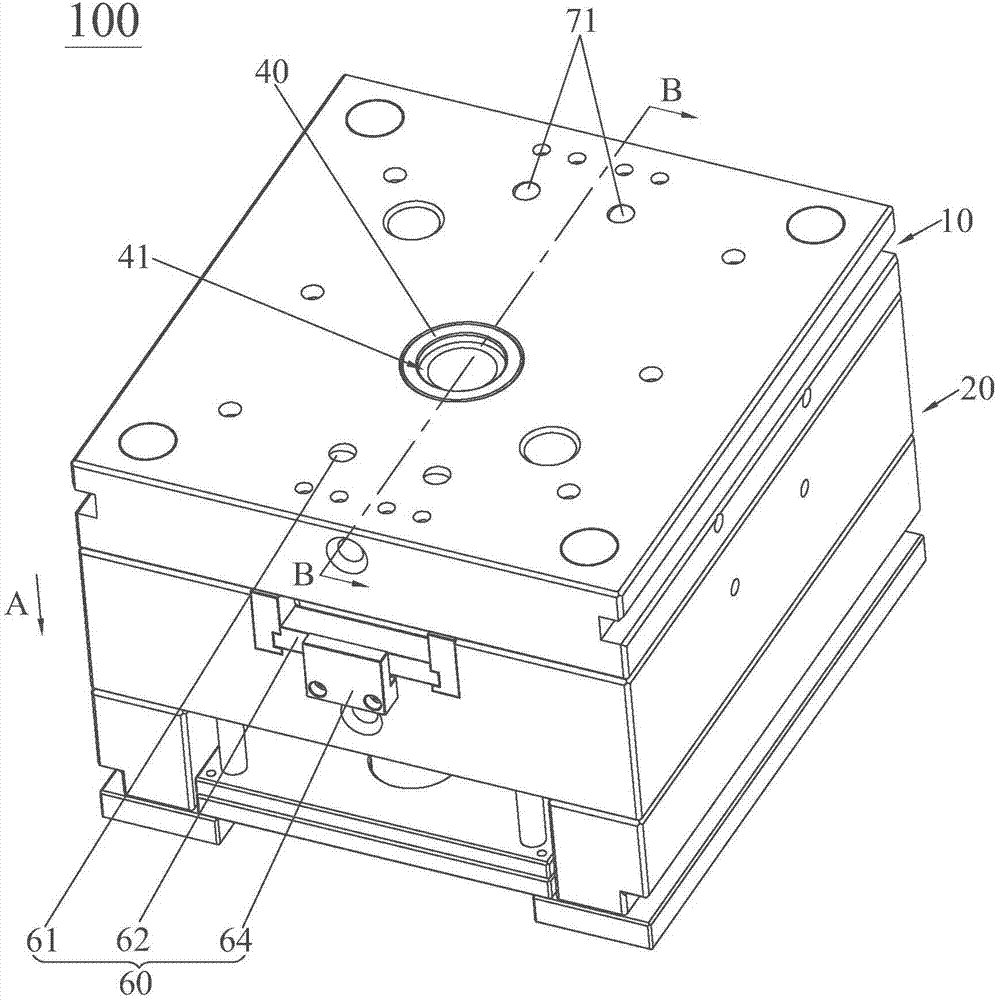

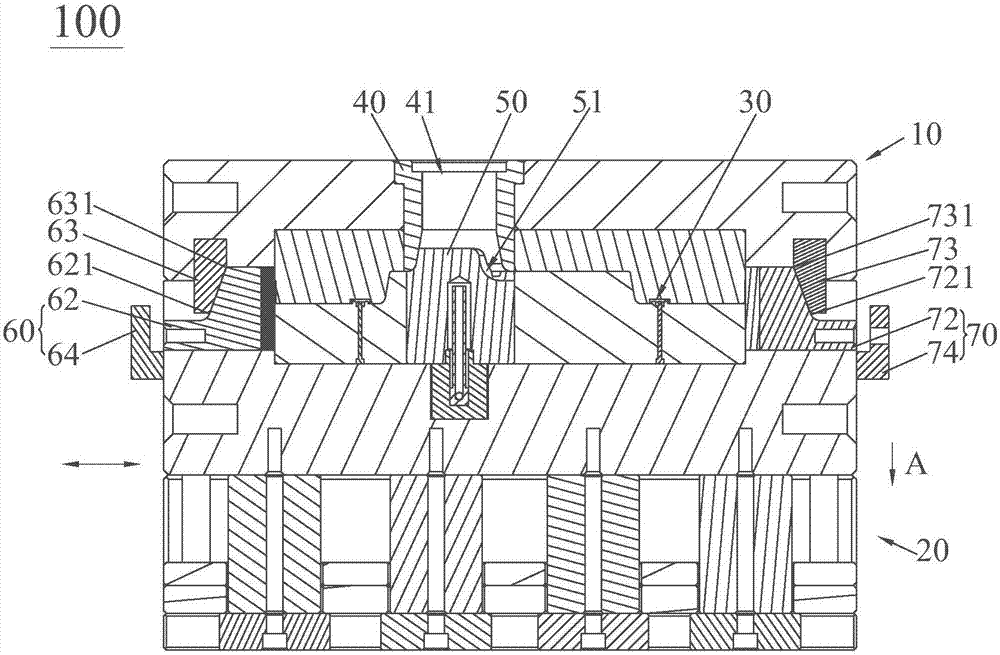

[0022] see Figure 1 to Figure 3 , the die-casting mold 100 for an annular shell of the present invention is used to form an end-to-end closed annular shell 200, including a pouring nozzle 40, a splitter cone 50, a left side pumping mechanism 60, a right side pumping mechanism 70, and fixed Die 10 and moving die 20. The fixed mold 10 and the movable mold 20 jointly enclose a ring cavity 30 closed end to end after the mold is closed. The pouring nozzle 40 and the splitter cone 50 are located in the space surrounded by the ring cavity 30. The pouring nozzle 40 is installed on the fixed mold 10. The splitter cone 50 is installed on the movable mold 20 and defines a splitter groove 51 connected with the sprue of the pouring nozzle 40 .

[0023] The left drawing mechanism 60 includes an oblique guide column 61 installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com