Forging die with punch convenient to replace

A technology of punches and dies, which is applied in the field of forging dies for easy replacement of punches, can solve problems such as troublesome replacement of punches, impact on production efficiency, damage of punches, etc., to save time, improve work efficiency, and save replacement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

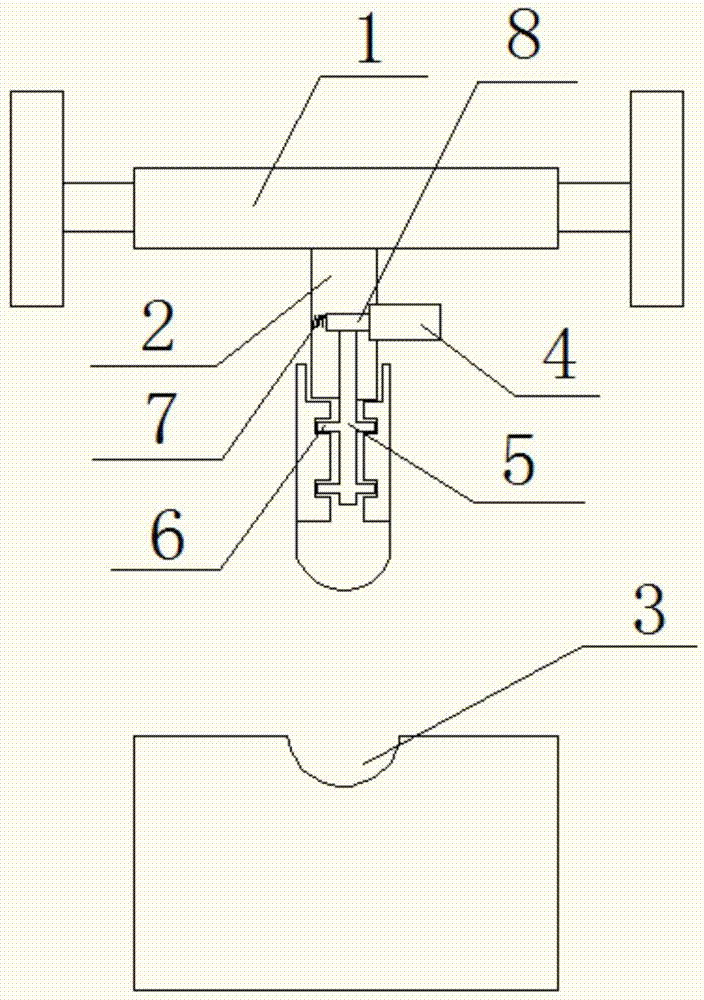

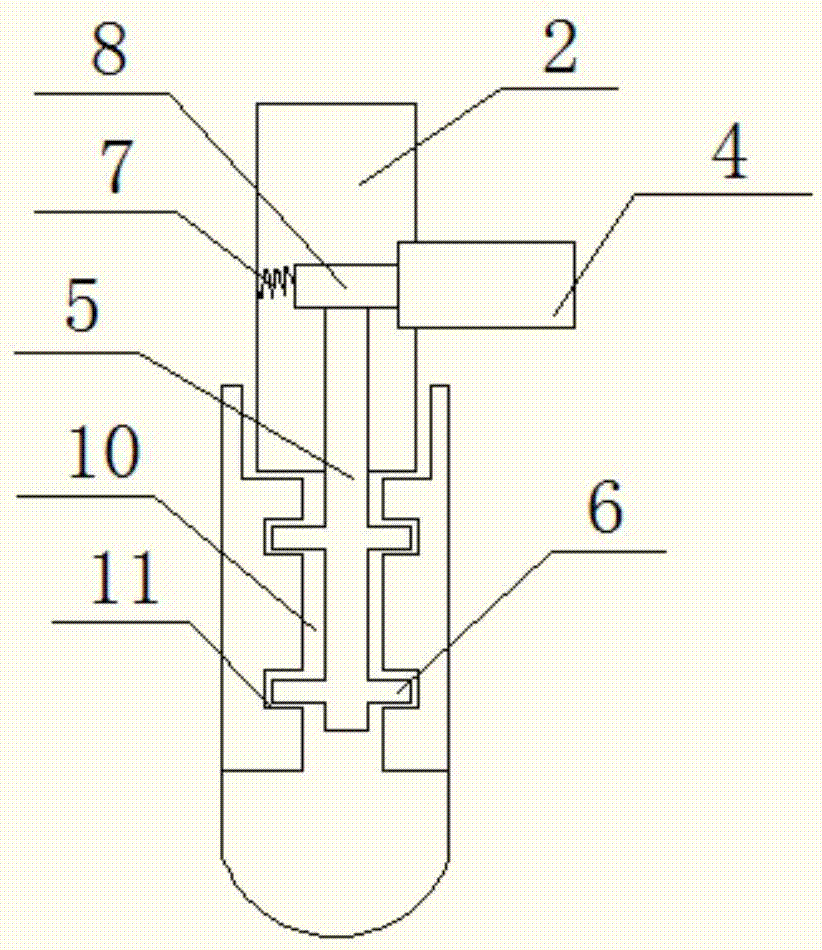

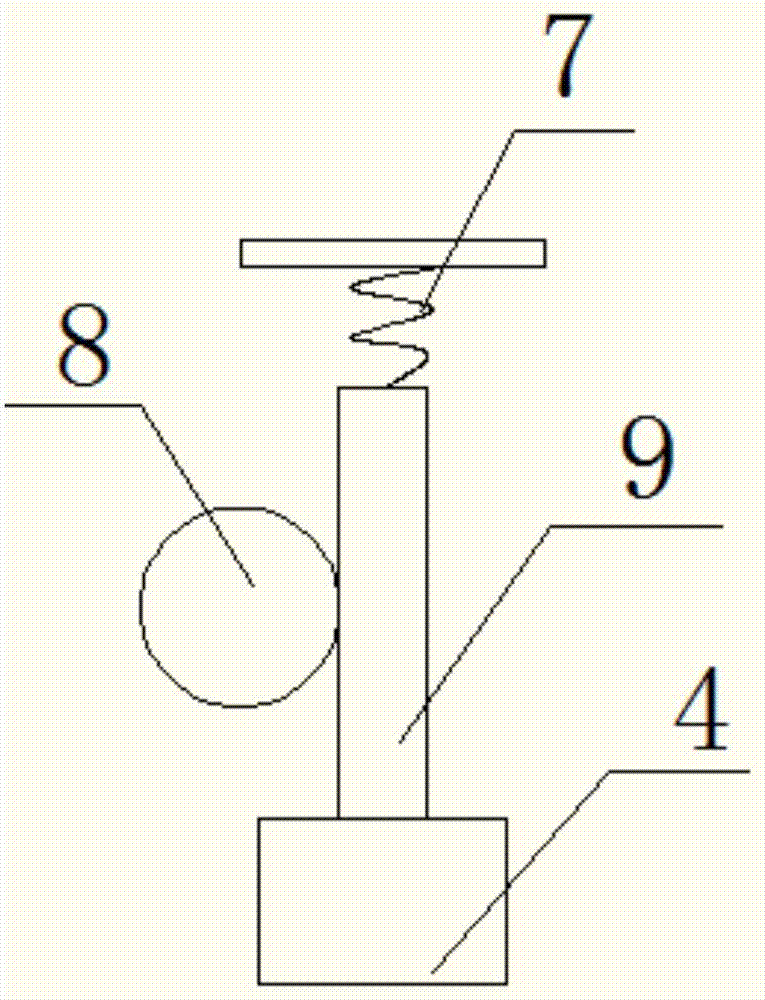

[0015] figure 1 Among them, a forging die that is easy to replace the punch includes a matched upper die base and a lower die base, the upper die base includes a punch mounting base 1 and a punch arranged on the punch mounting base 1, and the lower die base A forging groove 3 matching the punch is provided, a connecting rod 2 is arranged between the punch mounting seat 1 and the punch, and a locking rod 5 is arranged inside the connecting rod 2, and the locking rod 5 extends into the punch, and the inside of the punch An accommodating groove 10 for the lock bar 5 to pass through is provided, and a stopper 6 protrudes from the lock bar 5. On the side wall of the accommodating groove 10, a card slot 11 matching with the stopper 6 is provided, and the lock bar 5 is located on the One end in the connecting rod 2 is provided with a toothed disc 8, the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com