Detergent composition containing polyhydroxy compound

A polyhydroxy compound and composition technology, applied in the field of daily chemicals, can solve the problems of high odor of anti-dandruff agent, increase product irritation, and many restrictions on formula use, and achieve the effect of high mildness and low irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

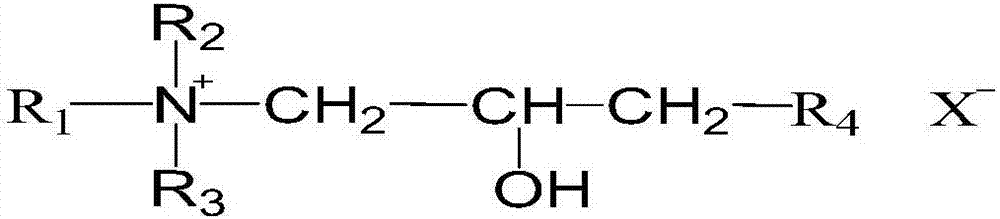

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

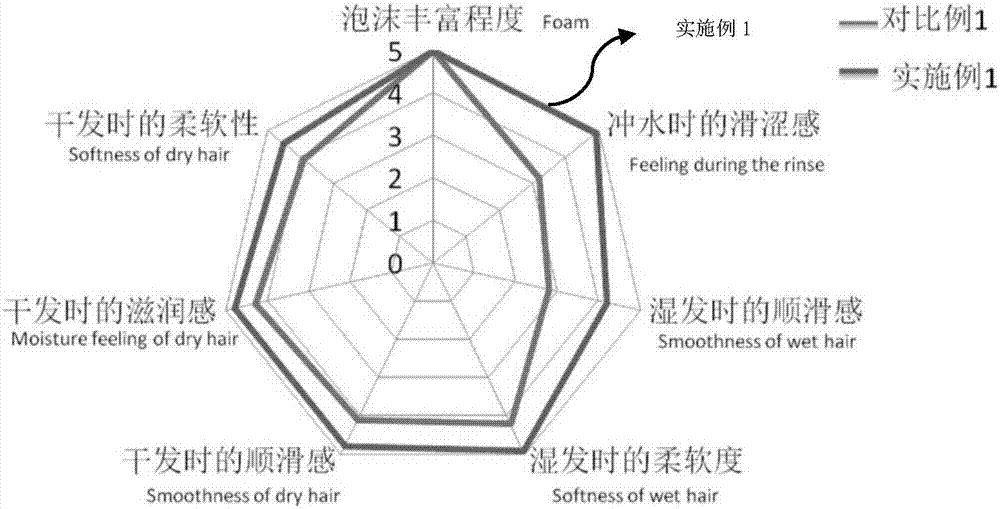

Embodiment 1

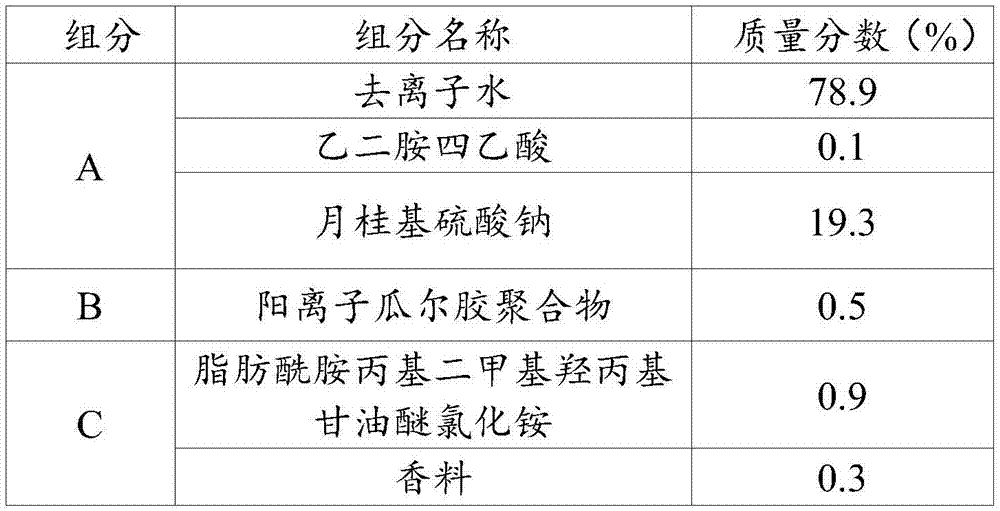

[0035] In this embodiment, a detergent composition containing a polyol is prepared:

[0036] (1) Formula components

[0037]

[0038] (2) Formulation process

[0039] a. Heat and stir phase A to dissolve evenly.

[0040] b. After phase A dissolves evenly, add phase B and continue heating and stirring to dissolve evenly.

[0041] c. After phase B is evenly dissolved, cool down to room temperature, add phase C, and stir evenly.

Embodiment 2

[0043] In this embodiment, a detergent composition containing a polyol is prepared:

[0044] (1) Formula components

[0045]

[0046] (2) Formulation process

[0047] a. Heat and stir phase A to dissolve evenly.

[0048] b. After phase A dissolves evenly, add phase B and continue heating and stirring to dissolve evenly.

[0049] c. After phase B is evenly dissolved, cool down to room temperature, add phase C, and stir evenly.

Embodiment 3

[0051] In this embodiment, a detergent composition containing a polyol is prepared:

[0052] (1) Formula components

[0053]

[0054] (2) Formulation process

[0055] a. Heat and stir phase A to dissolve evenly.

[0056] b. After phase A dissolves evenly, add phase B and continue heating and stirring to dissolve evenly.

[0057] c. After phase B is evenly dissolved, cool down to room temperature, add phase C, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com