An improved coffee machine

A technology of coffee machine and body, which is applied to kitchen utensils, home utensils, beverage preparation devices, etc., can solve problems such as not conforming to hand-brewed coffee, and achieve the effects of increasing observability, speeding up brewing speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

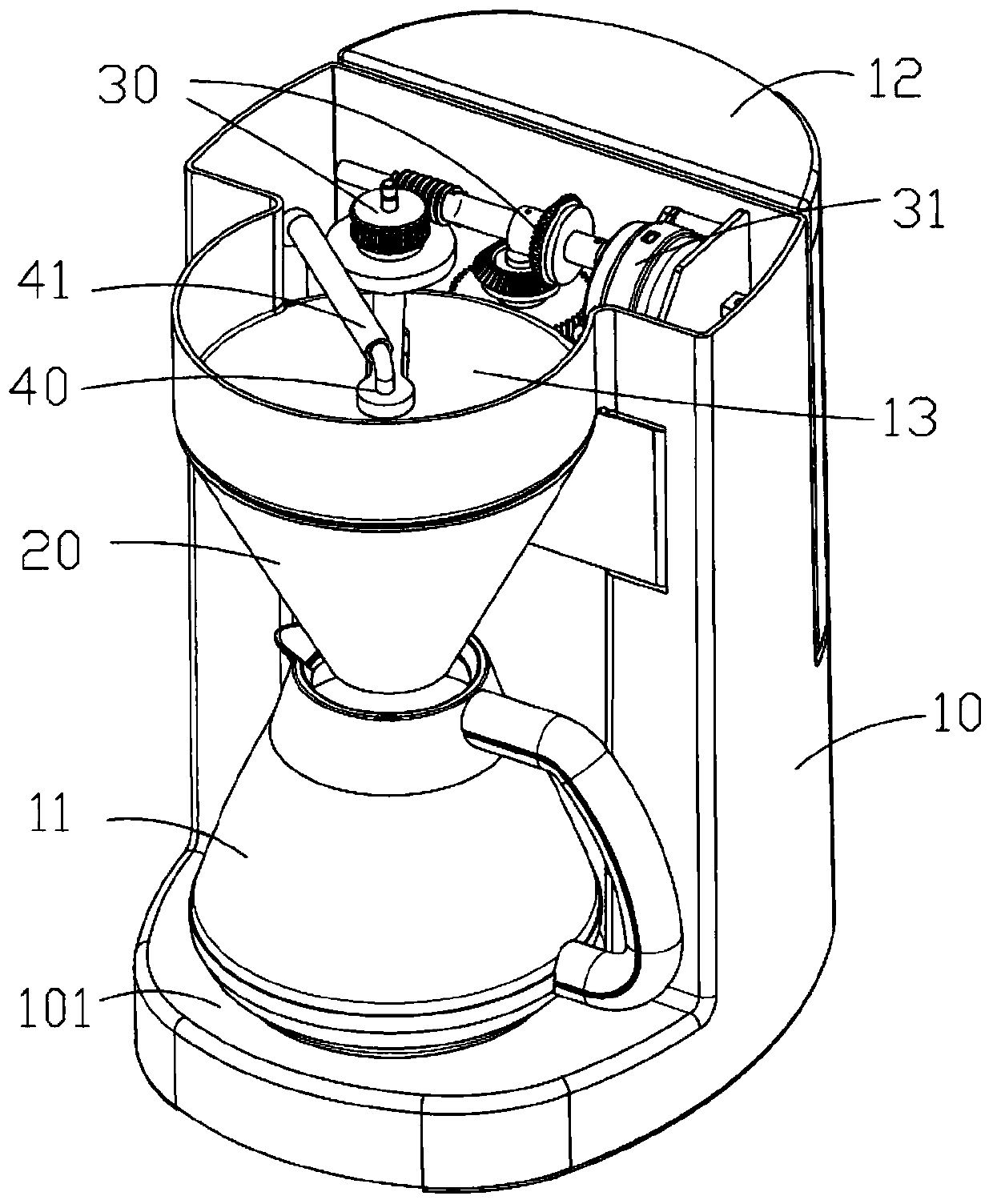

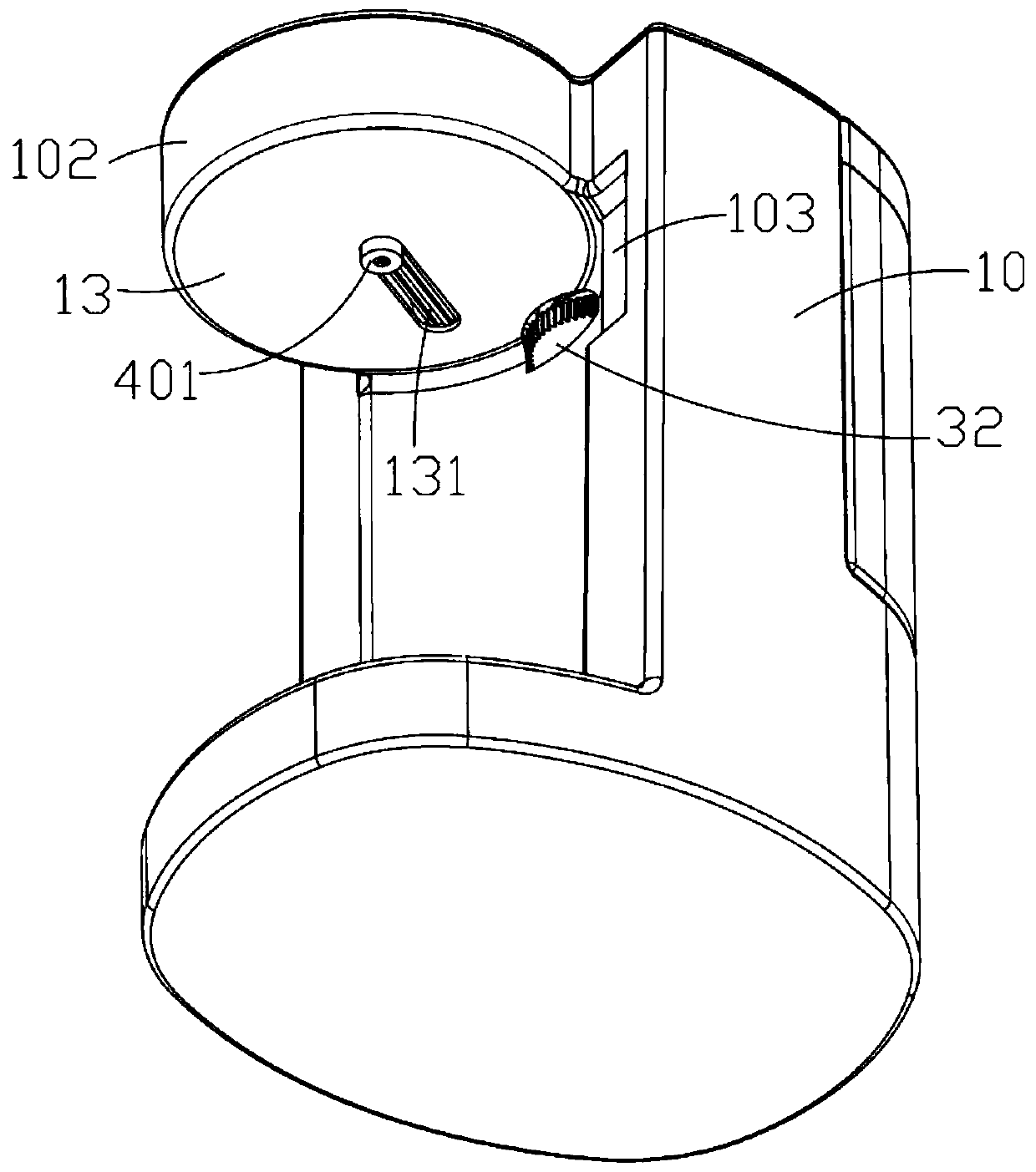

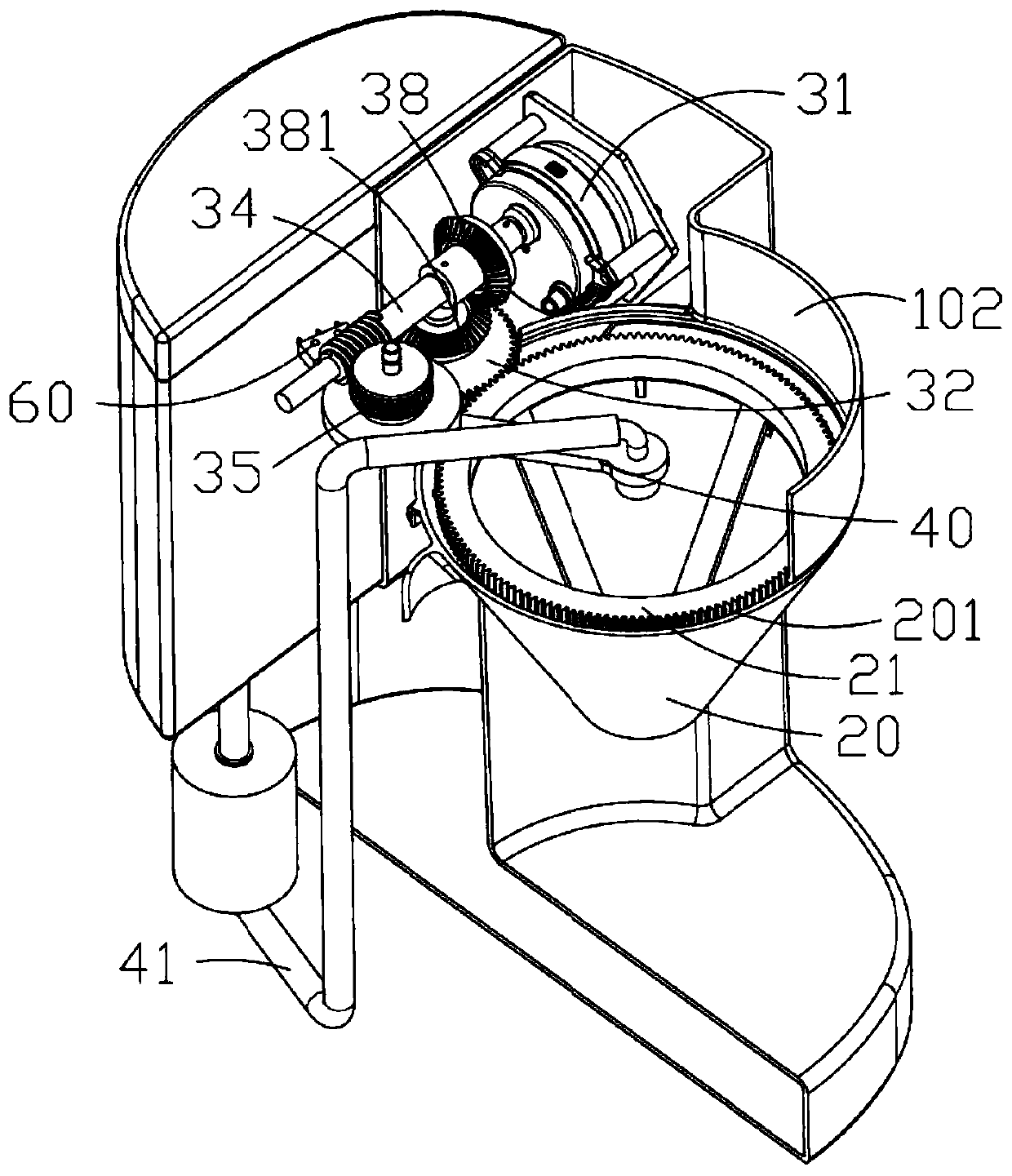

[0053] Such as figure 1 As shown, an improved coffee machine includes a body 10, a water storage device 12 and a water injection part 40. The water storage device 12 is located inside the body 10. The water injection part 40 is connected to the water storage device 12 through a hose 41. The water injection part 40 A baffle 13 connected to the machine body 10 is provided below, and a brewing basket assembly 20 is provided below the baffle 13 . See figure 2 , the baffle 13 is provided with a radial groove 131, the water injection part 40 is driven by the power mechanism 30 to reciprocate radially along the groove 131, the brewing basket assembly 20 includes a filter cup 21 and a brewing basket 22, the filter cup 21 is placed in the brewing The bubble basket 22 is driven by the power mechanism 30 to rotate circumferentially.

[0054] Such as figure 1 with figure 2 As shown, the body 10 is in the shape of a "concave" placed sideways, and includes a cup holder 101 for placing...

Embodiment 2

[0064] The coffee machine of the second embodiment is substantially the same as that of the first embodiment, except for the power mechanism 30 .

[0065] In this embodiment, the power mechanism 30 such as Figure 13 with Figure 14 As shown in , includes a second motor 33, the second motor 33 drives the second spur gear 39 to rotate, the filter cup 21 of the brewing basket assembly 20 is provided with a first gear structure 201, the first gear structure 201 and the second spur gear 39 Compatible (see Figure 5 with Image 6 ); the power mechanism 30 also includes a third motor 36, the third motor 36 drives the second worm 37 to rotate, and the second worm 37 is compatible with the worm gear 35 to form a worm gear transmission, and the worm gear 35 is pivotally connected with the water injection part 40 (see Figure 13 with Figure 14 ).

[0066] The power mechanism 30 includes a second motor 33, the second motor 33 is fixedly arranged on the body 10, the shaft of the sec...

Embodiment 3

[0068] The coffee machine of the third embodiment is substantially the same as that of the second embodiment, the difference lies in the brewing basket assembly 20 .

[0069] Such as Figure 15-Figure 18 As shown, the brewing basket assembly 20 also includes a rotating ring 23, which is placed on the upper surface of the baffle plate 13, and the first gear structure 201 is arranged on the outer peripheral surface of the rotating ring 23 (see Figure 17 ), the rotating ring 23 is also provided with a first attractor 231, and the opening 211 of the filter cup 21 is provided with a second attractor 214 at a position corresponding to the first attractor 231 (see Figure 16 ), the rotating ring 23 drives the filter cup 21 to rotate through the magnetic force generated between the first attracting member 231 and the second attracting member 214 .

[0070] In this embodiment, the brewing basket assembly 20 includes a filter cup 21, a brewing basket 22 and a rotating ring 23, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com