Making method of candied Chinese chestnuts

A technology of chestnut and preserved fruit, which is applied in confectionary, confectionery industry, food science, etc., can solve the problems of starch aging and regeneration, preserved fruit is easy to break, and high starch content, so as to improve plumpness, good anti-oxidation effect, and degradation ability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

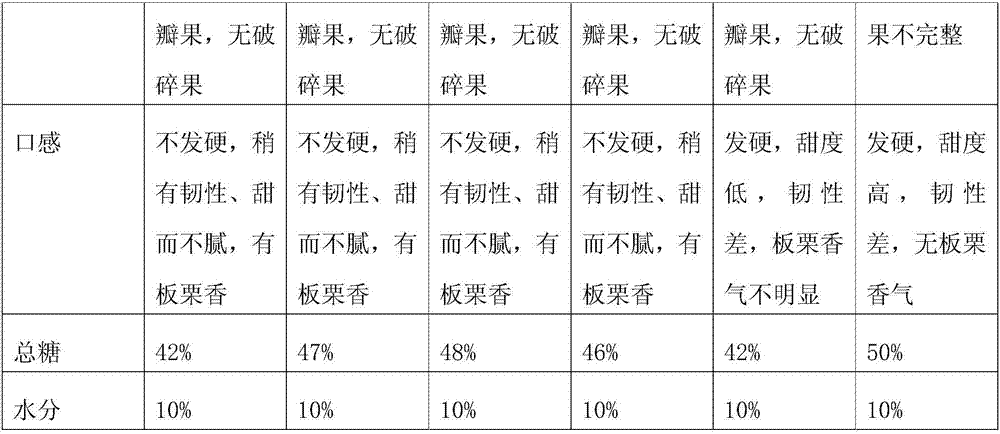

Examples

Embodiment 1

[0026] A kind of preparation method of preserved chestnut comprises the steps:

[0027] (1) Raw material pretreatment: shell the chestnut and peel off the skin, boil the chestnut in water for 5 minutes;

[0028] (2) Color protection: soak the chestnut in the color protection solution containing chestnut shell extract for 5 minutes; in the color protection solution, the mass percentage of chestnut extract is 25%; the chestnut shell The extract is extracted by the following method: dry the chestnut shell and crush it through a 200-mesh sieve, put the chestnut shell in a supercritical extraction kettle, and use ethyl acetate as an entrainer for supercritical CO extraction. 2 Extraction 10min; The supercritical CO 2 The extraction conditions are: temperature 25°C, extraction pressure 30MPa, CO 2 The flow rate is 15L / min; the ratio of the mass of ethyl acetate to chestnut shell is 1:100; the content of caffeic acid in the extract of chestnut shell is not less than 23mg / 100g, the ...

Embodiment 2

[0033] A kind of preparation method of preserved chestnut comprises the steps:

[0034] (1) Raw material pretreatment: shell the chestnut and peel off the skin, boil the chestnut for 3 minutes;

[0035] (2) Color protection: soak the chestnut in the color protection solution containing chestnut shell extract for 10 minutes; in the color protection solution, the mass percentage of chestnut extract is 20%; the chestnut shell The extract is extracted by the following method: dry the chestnut shell and crush it through a 200-mesh sieve, put the chestnut shell in a supercritical extraction kettle, and use ethyl acetate as an entrainer for supercritical CO extraction. 2 Extraction 12min; The supercritical CO 2 The extraction conditions are: temperature 25°C, extraction pressure 30MPa, CO 2The flow rate is 15L / min; the ratio of the mass of ethyl acetate to chestnut shell is 0.1:100; the content of caffeic acid in the extract of chestnut shell is not less than 23mg / 100g, the content...

Embodiment 3

[0040] A kind of preparation method of preserved chestnut comprises the steps:

[0041] (1) Raw material pretreatment: shell the chestnut and peel off the skin, boil the chestnut for 4 minutes;

[0042] (2) Color protection: soak the chestnut in the color protection solution containing the chestnut shell extract for 8 minutes; in the color protection solution, the mass percentage of the chestnut extract is 23%; the chestnut shell The extract is extracted by the following method: dry the chestnut shell and crush it through a 200-mesh sieve, put the chestnut shell in a supercritical extraction kettle, and use ethyl acetate as an entrainer for supercritical CO extraction. 2 Extraction 11min; The supercritical CO 2 The extraction conditions are: temperature 25°C, extraction pressure 30MPa, CO 2 The flow rate is 15L / min; the ratio of ethyl acetate to chestnut shell mass is 0.5:100; the content of caffeic acid in the chestnut shell extract is not less than 23mg / 100g, the content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com