Three-level Boost converter neutral-point potential balance control method

A potential balance and control method technology, applied in the field of multi-level conversion, can solve the problems of low control accuracy and dynamic response speed, complex coupling relationship, unfavorable controller design, etc., to improve the type and phase angle margin. , to ensure no static difference adjustment, improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

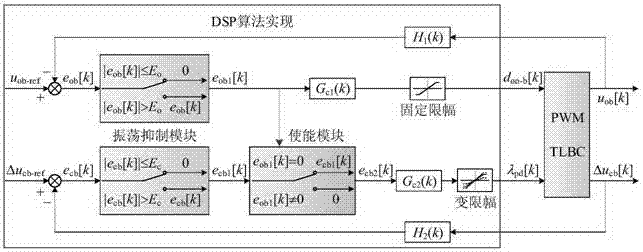

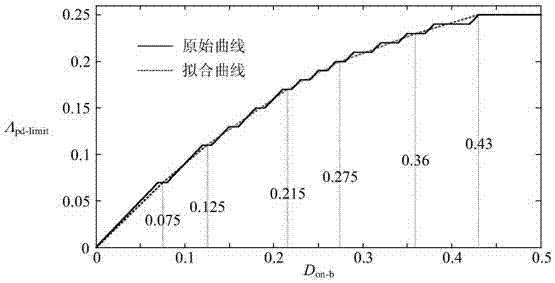

[0039] Optimize and improve the pulse phase delay control method of the previous three-level Boost converter, adopt a modeling method based on the inductor current ripple, establish an accurate mathematical model of the output voltage and the deviation voltage, and derive the subsection of the deviation voltage gain characteristic coefficient Analyze the expression, and use the segmental fitting method of the maximum deviation voltage condition to determine the phase delay boundary conditions in different duty cycle intervals, and then design dual-loop controllers with different bandwidths, and optimize the controller parameters to increase the output voltage. The dynamic performance of the ring, and ensure the non-static adjustment of the deviation voltage ring.

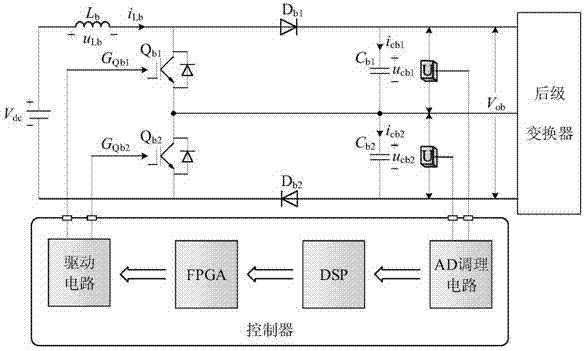

[0040] Five, the realization scheme of the present invention

[0041] The present invention proposes a method for controlling the midpoint potential balance of a three-level Boost converter. The specific logic proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com