Aluminum-plastic film punching structure and method for a soft-pack lithium-ion battery

A lithium-ion battery and ion battery technology, applied in the field of aluminum-plastic film punching, can solve the problems of less adjustment factors, reduced design space, and limited adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

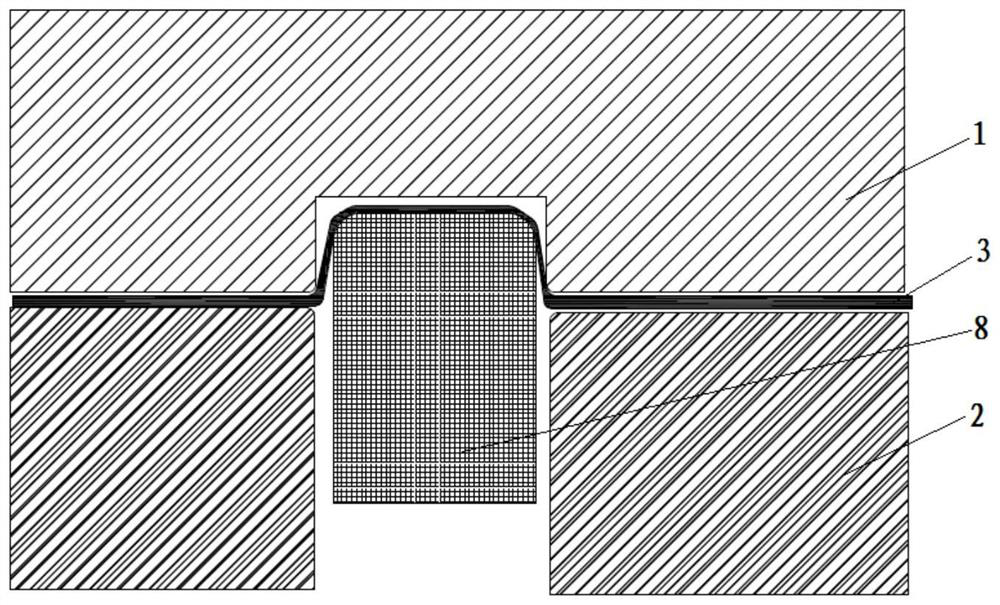

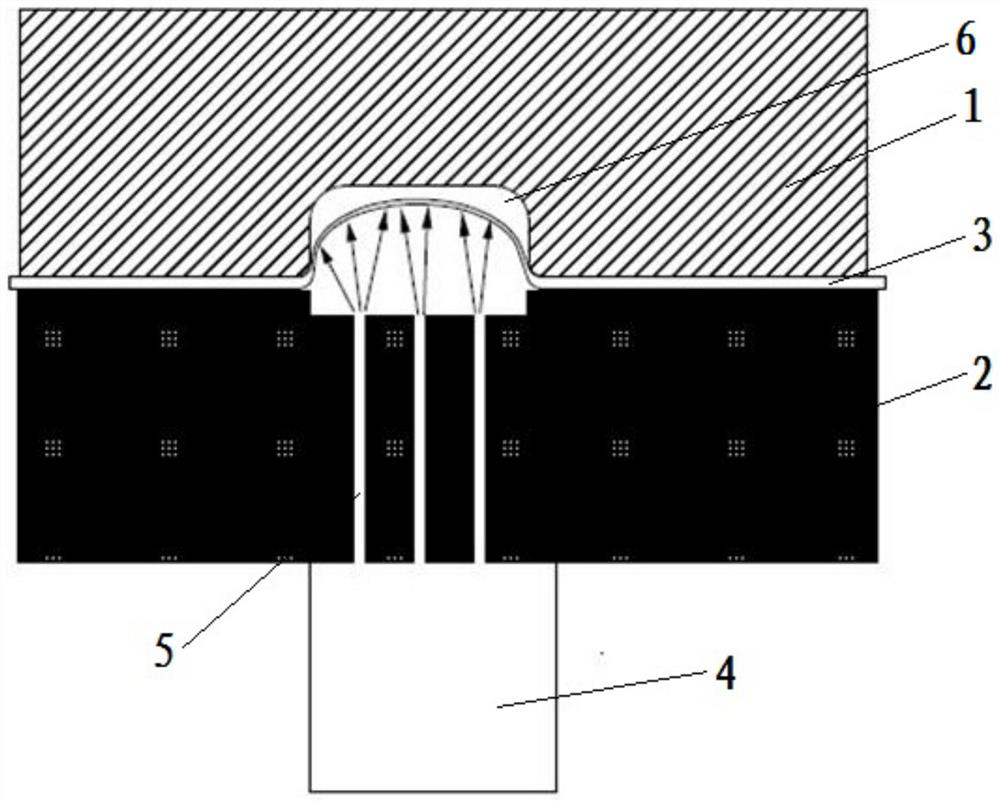

[0037] Such as image 3 with Figure 5 As shown, the aluminum-plastic film punching structure of a soft-packed lithium-ion battery according to the present invention includes a lower template 2 and an upper template 1 fixedly connected with the lower template 2, and the aluminum-plastic film 3 is fixed on the upper template 1 and the lower template 2, the bottom surface of the upper template 1 is provided with a groove 6 for punching and shaping the aluminum-plastic film 3, and the lower template 2 is provided with a through hole 5 passing through the lower template 2 at a position directly below the groove 6. The bottom of the template 2 is provided with a high-pressure compressed gas bottle 4 communicating with the through hole 5 .

[0038] It should be noted that the number of through holes 5 is provided in multiples, and the plurality of through holes 5 are evenly arranged on the lower template 2 at the position directly below the groove 6, and the bottom surface of the u...

Embodiment 2

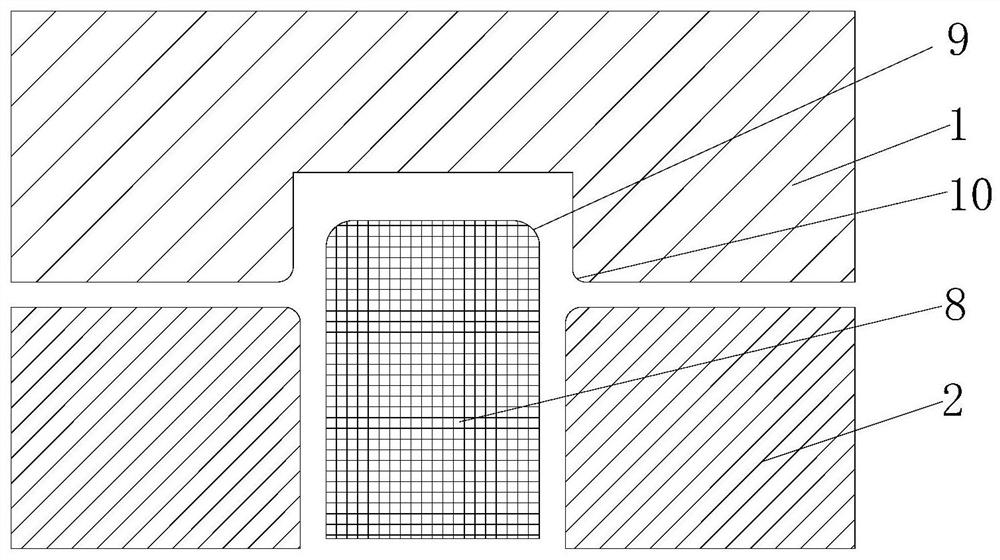

[0048] Such as Figure 4 with Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the side of the lower formwork 2 close to the groove 6 is provided with a memory rubber bag 7 communicating with the through hole 5 .

[0049] In this embodiment, the memory rubber bag 7 is a hollow elastic memory rubber bag.

[0050] It should be noted that the memory rubber bag 7 is made of plastic material, and the memory rubber bag 7 is filled with the high-pressure gas output from the high-pressure compressed gas cylinder 4. The purpose is to make a deformable punch instead of the original rigid punch 8 Before the high-pressure compressed gas cylinder 4 is opened, the memory rubber bag 7 shrinks into the lower template 2, which occupies a small volume and is compressible. After the high-pressure compressed gas cylinder 4 is opened, the high-pressure gas enters the memory rubber bag 7 through the through hole 5, pushing The stretching and expansion of the mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com