Copper oxide nonenzymatic glucose electrochemical sensor

A technology of copper oxide and glucose, which is applied in the detection field, can solve the problems of easy poisoning and high price, and achieve the effect of excellent selectivity and excellent performance of glucose detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

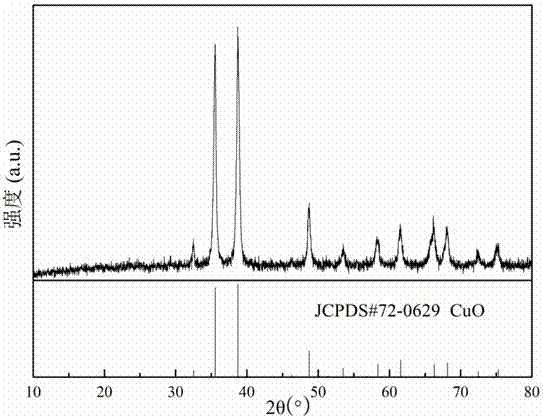

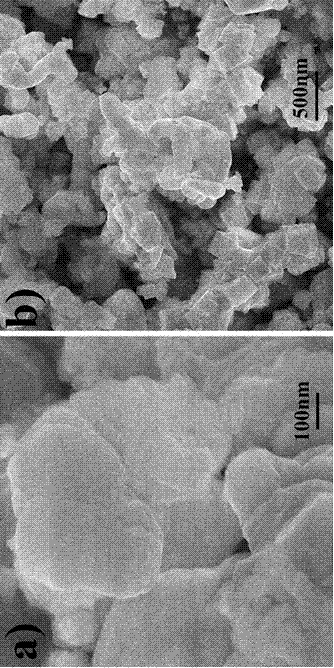

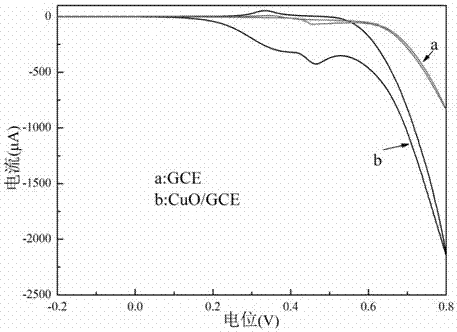

[0040] Preparation of a raspberry-shaped copper oxide material and construction of a non-enzymatic glucose sensor, including the preparation of raspberry-shaped copper oxide, the preparation of the raspberry-shaped copper oxide: Weigh 0.2 g P123 and dissolve it in 3.8 mL ethanol, ultrasonic 15 min to dissolve, add 0.399 g copper nitrate and 0.045 g HMT to sonicate until dissolved, and obtain a stable solution, add 46 mL of ethylene glycol, high-density ultrasonic for 30 min, and react at 200 °C for 24 hours to obtain a precipitate. washed three times with ethanol, dried in a vacuum oven at 60°C for 12 hours, and calcined at 400°C for 2 hours to obtain a black copper oxide solid. Preparation of modified glassy carbon electrode: Weigh a small amount of the solid, add 0.5% Nafion solution and ethanol solution, ultrasonically disperse it into an ink-like state, apply the dispersed liquid onto the surface of the previously treated glassy carbon electrode, and dry it in the air to ob...

Embodiment 2

[0042] Preparation of a raspberry-shaped copper oxide material and construction of a non-enzymatic glucose sensor, including the preparation of raspberry-shaped copper oxide, the preparation of the raspberry-shaped copper oxide: Weigh 0.1 g P123 and dissolve it in 3.8 mL ethanol, ultrasonic 15 min to dissolve, add 0.399 g copper nitrate and 0.070 g HMT ultrasonic to dissolve to obtain a stable solution, add 46 mL ethylene glycol, high-density ultrasonic 30 min, and react at 200 °C for 24 hours to obtain a precipitate, wash it three times with deionized water, Wash with ethanol three times, dry in a vacuum oven at 60°C for 12 hours, and calcinate the product at 400°C for 2 hours to obtain a black copper oxide solid. Preparation of modified glassy carbon electrode: Weigh a small amount of the solid, add 0.5% Nafion solution and ethanol solution, ultrasonically disperse it into an ink-like state, apply the dispersed liquid onto the surface of the previously treated glassy carbon e...

Embodiment 3

[0044] Preparation of a raspberry-shaped copper oxide material and construction of a non-enzymatic glucose sensor, including the preparation of raspberry-shaped copper oxide, the preparation of the raspberry-shaped copper oxide: Weigh 0.2 g P123 and dissolve it in 3.8 mL ethanol, ultrasonic 15 min to dissolve, add 0.399 g copper nitrate and 0.045 g HMT ultrasonic to dissolve, obtain a stable solution, add 46 mL ethylene glycol, high-density ultrasonic 30 min, and react at 200 ° C for 12 hours to obtain a precipitate. washed three times with ethanol, dried in a vacuum oven at 60°C for 12 hours, and calcined at 400°C for 2 hours to obtain a black copper oxide solid. Preparation of modified glassy carbon electrode: Weigh a small amount of the solid, add 0.5% Nafion solution and ethanol solution, ultrasonically disperse it into an ink-like state, apply the dispersed liquid onto the surface of the previously treated glassy carbon electrode, and dry it in the air to obtain CuO / GCE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com