Jet nozzle of mild combustion chamber of gas turbine

A technology of jet nozzles and gas turbines, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of unfavorable establishment and realization of soft combustion, reduction of flue gas return ratio, large pressure loss, etc., so as to facilitate practical application and operation , reduce the peak flame temperature, reduce the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

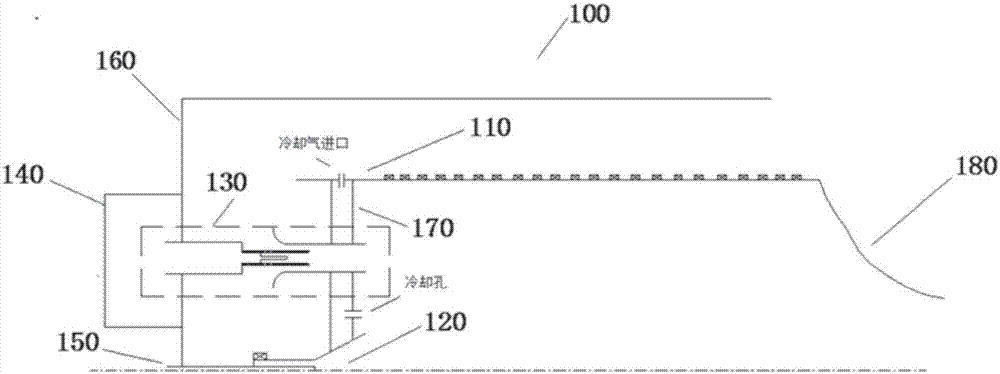

[0043] The invention provides a soft combustion chamber jet nozzle, and several jet nozzles are important components of the nozzle assembly of the combustion chamber head. The composition of the general soft combustion chamber is as follows: figure 1 Shown: soft combustor 100, combustor flame barrel 110, duty swirl nozzle 120, jet nozzle 130, main fuel pipe 140, duty fuel pipe 150, combustor casing 160, combustor head baffle 170 and combustor transition section 180 .

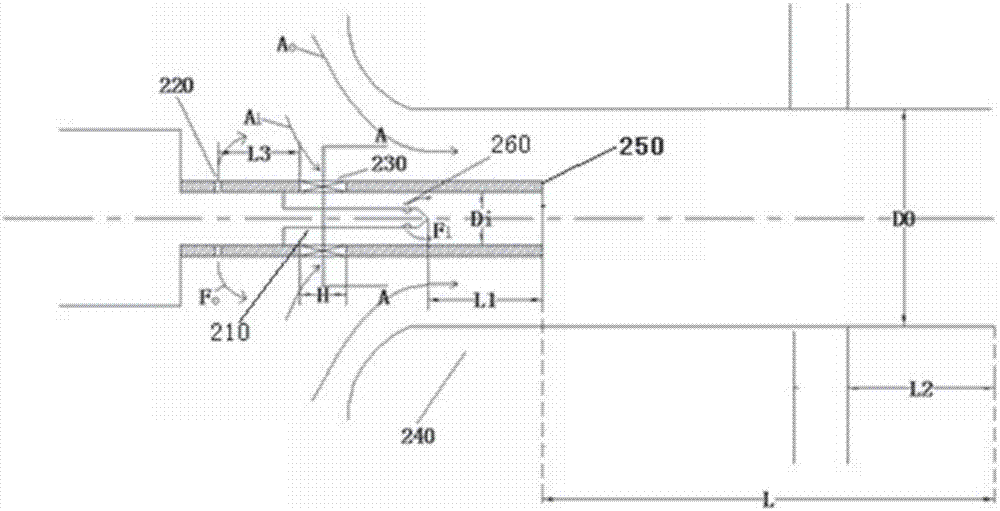

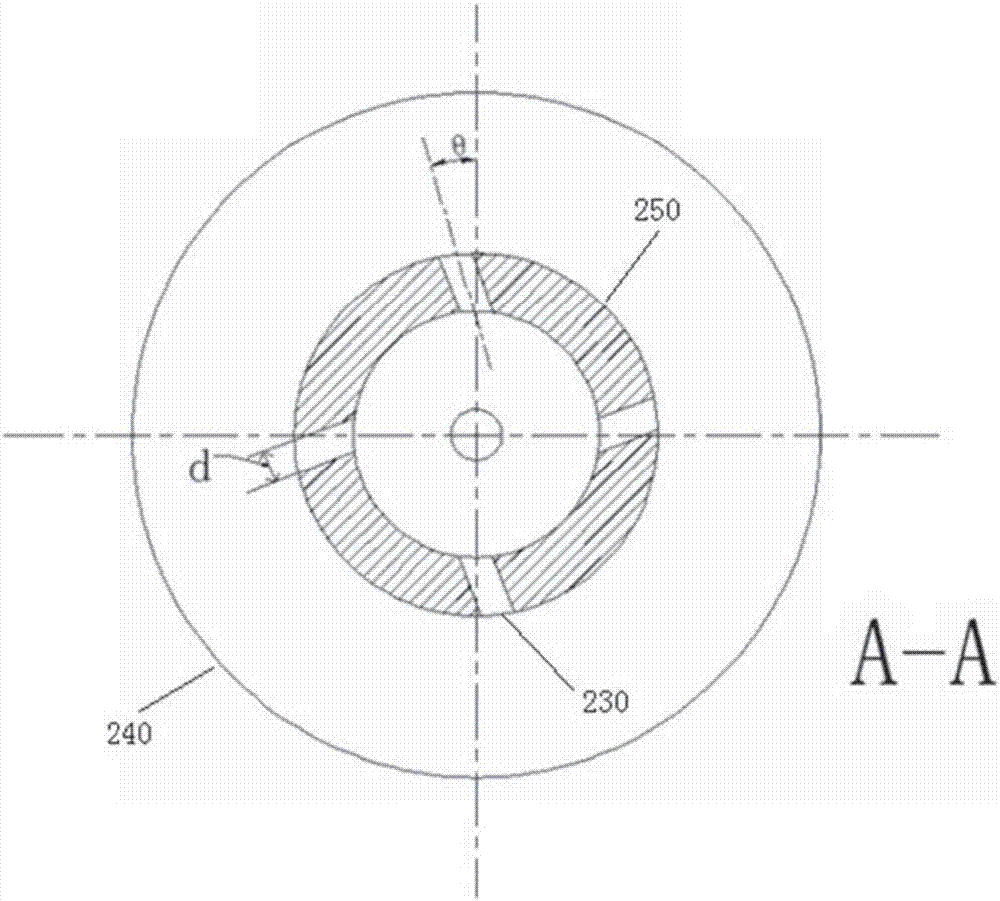

[0044] Such as figure 2 As shown, the jet nozzle 130 of the present invention comprises a fuel inner nozzle 210, a fuel outer injection hole 220, a swirl channel 230, an outer pipe 240 and an inner pipe 250, and the outer pipe 240 is fixed on the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com