Feeding adjustable locking device for biomass forming fuel boiler

A technology of forming fuel and locking device, which is applied in the directions of supply configuration, fuel supply, combustion method, etc., can solve the problems of furnace deflagration or sudden increase in positive pressure, inability to realize adjustable fuel opening, and large proportion of flammable volatile matter. , to achieve the effect of increasing the scope of use, convenient and easy self-locking, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

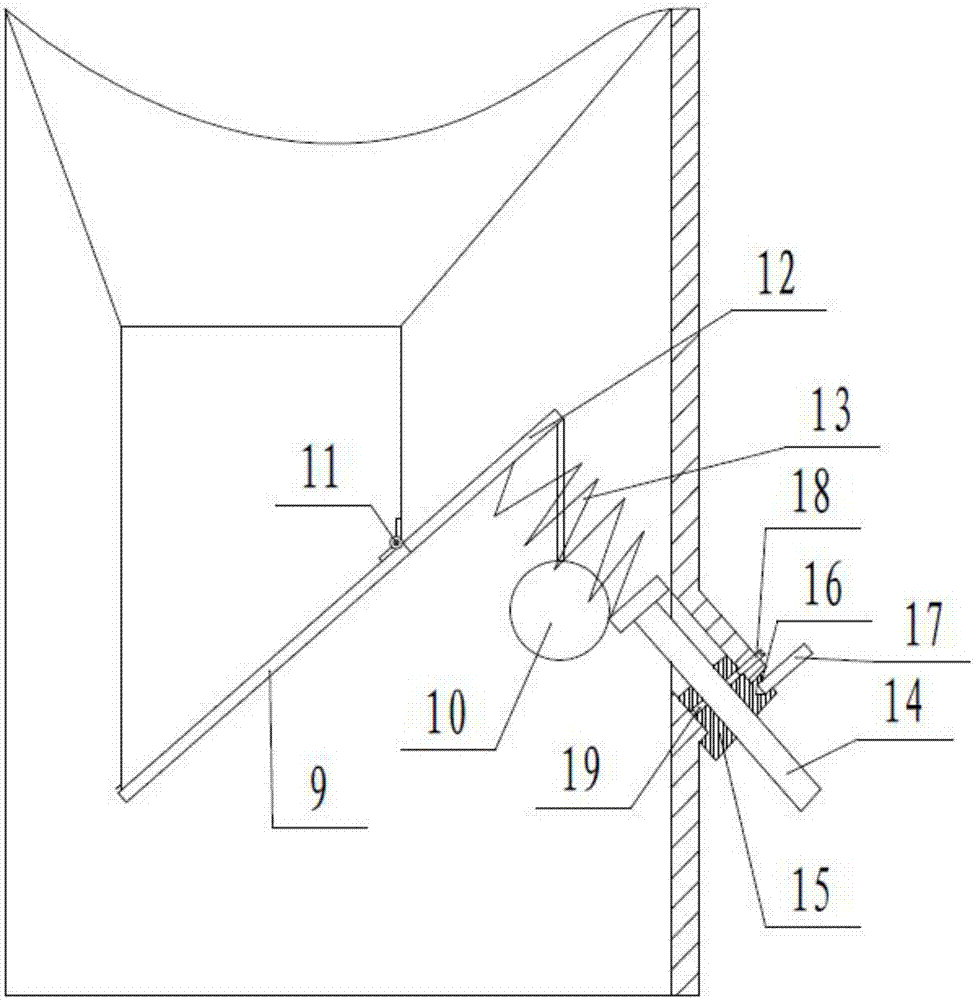

[0014] Embodiment 1: as figure 2 As shown, a biomass briquette fuel boiler feeding adjustable locking device includes an inclined flap 9 and a gravity hammer 10. The flap 9 is connected to the lower end of the drop tube 3 and connected to the drop tube 3 through a hinge 11. A section of the cantilever rod 12 extends from the side of the lower end and the connecting end of the flap. The end of the cantilever rod 12 is fixedly connected to the gravity hammer 10 through the suspension rod. The force adjustment device is installed on the cantilever rod. The structure is simple, self-locking is convenient and easy, and the cost is low. The flap-type air lock with this structure can effectively prevent clogging, feed more evenly, and prevent high-temperature smoke and open flames from entering the feeder and hopper, preventing fuel in the fuel hopper from being diverted.

[0015] Preferably, there are two gravity hammers 10, which are symmetrically arranged at the front and rear en...

Embodiment 2

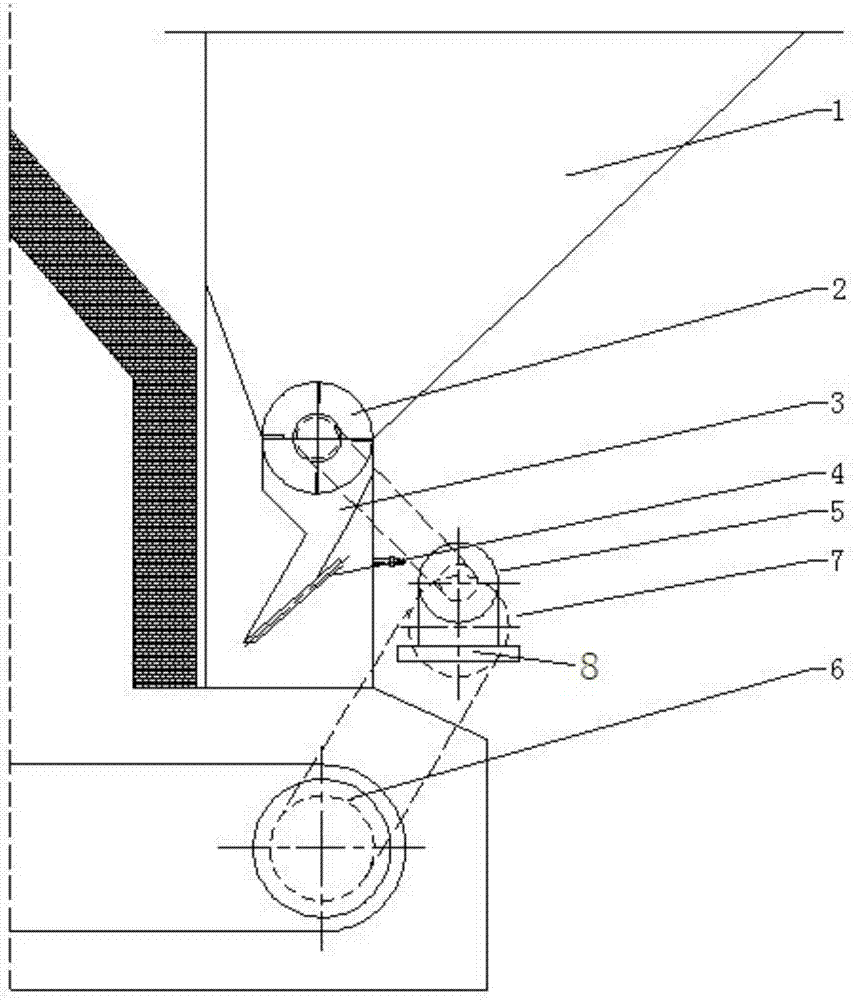

[0017] Embodiment 2: as Figure 1-2 As shown in the figure, an adjustable locking device for biomass briquette fuel boiler includes a front feed bin 1, a feeder 2, a feeding pipe 3 and an adjustable locking device 4. The adjustable locking device adopts a flap lock The gas device, the front feed bin 1 is in the shape of a trumpet with a large top and a small bottom. The feeder 2 is installed at the lower end of the furnace feed bin 1, and the lower end of the furnace feed bin 1 is connected to the boiler’s drop pipe 3, which is The lower end is connected with an adjustable locking device 4.

[0018] Preferably, the above-mentioned material shifter 2 is connected to the primary shift output shaft of the transmission 7 through a primary belt transmission mechanism, and the secondary transmission output shaft of the transmission 7 is connected to the grate main shaft 6 through a secondary belt transmission mechanism, and the input of the transmission 7 The shaft is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com