Efficient axial centrifugal fan

A centrifugal fan, high-efficiency technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem that reliability and service life do not meet user requirements, structural performance does not meet design requirements, and airflow velocity gradient does not meet the requirements. Equalize the problem to achieve the effect of improving head and efficiency, reducing weight, impeller flatness and end runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

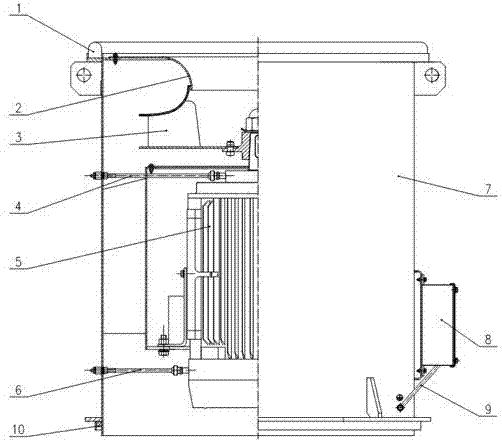

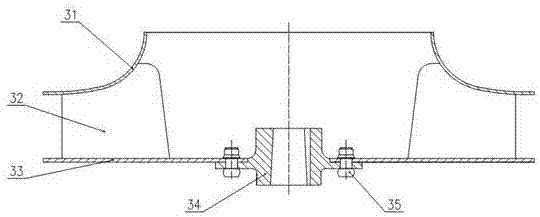

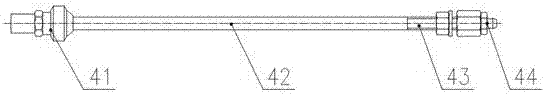

[0020] refer to figure 1 , figure 2 , image 3 with Figure 4 , a high-efficiency axial centrifugal fan, including an upper sealing ring 1, an air inlet duct 2, an impeller 3, a front-end filling pipe 4, a motor 5, a rear-end filling pipe 6, an air cylinder 7, a junction box 8, a grounding wire 9, The lower sealing ring 10 is characterized in that:

[0021] The air cylinder 7 is provided with an upper sealing ring installation ring 71, lifting lug 72, outer cylinder 73, guide vane 74, inner cylinder 75, lower sealing ring installation ring 76, junction box mounting seat 77, reinforcing rib 78 and grounding Nut 79, wherein, the upper sealing ring installation ring 71 on the fan cylinder 7 and the lower sealing ring installation ring 76 are respectively provided with the upper sealing ring 1 and the lower sealing ring 10, which effectively reduces the vibration and impact from the car body, and at the same time The vibration of the fan itself is also blocked from propagatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com