Coiled tubing motive sealing device

A dynamic sealing and tubing technology, which is applied in the direction of sealing/packing, drilling pipe, casing, etc., can solve the problems of dynamic sealing devices and methods that have not been disclosed for coiled tubing injection or lifting, so as to improve the effect of hanging and removing, improve effect, effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

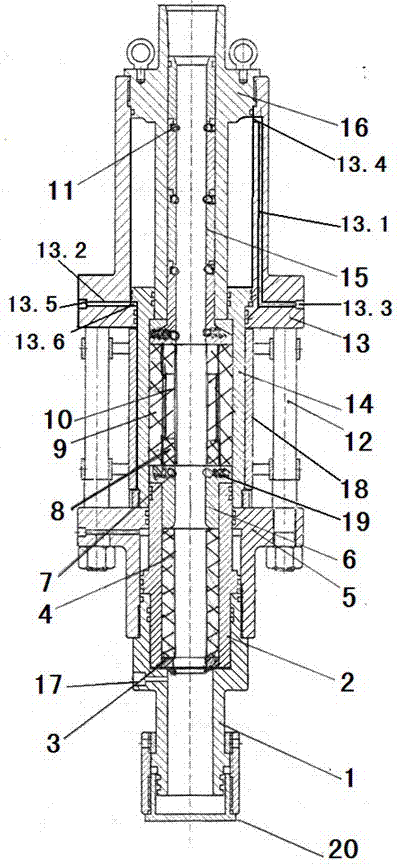

[0029]Embodiment 1, a coiled tubing dynamic sealing device mentioned in the present invention, its technical solution is: including a lower joint 1, a seat seal piston 2, a split ring oil wiper 3, an oil-expandable rubber 4, and a seat seal hydraulic cylinder 5 , rubber pressure ring 6, righting steel ball 7, easy-change rubber pad 8, sealing base sleeve 9, sealing rubber core 10, positioning and righting steel ball 11, connecting bolt 12, rubber replacement cylinder 13, sealing cylinder 14, rubber seat seal The base ring 15, the hollow mandrel 16, the limit support plate 18, the oil wiper 3 of the split ring are installed at the boss of the inner cavity of the lower joint 1, and the upper part of the lower joint 1 is movably connected with the seat seal hydraulic cylinder 5, and the seat seal hydraulic cylinder 5 Install the seat seal piston 2 in the inner cavity of the seat seal piston 2, install the oil-expandable rubber 4 in the inner cavity of the seat seal piston 2, and i...

Embodiment 2

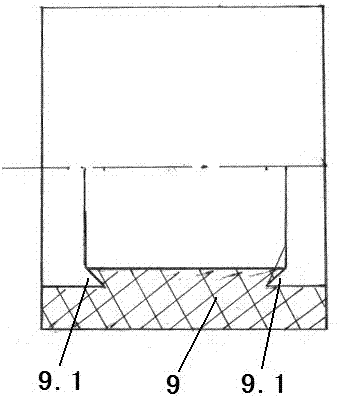

[0045] Embodiment 2, the easy-to-change rubber pad 8 adopted by the present invention is a ring-shaped structure, and an oblique cut is cut in the middle, so that it can be conveniently placed on the working coiled tubing through the oblique cut; in addition, the sealing base sleeve 9 of the present invention is Cylindrical structure, its outer diameter is not greater than the inner diameter of the sealing cylinder 14; the outer diameter of the sealing rubber core 10 is not greater than the inner diameter of the sealing base sleeve 9, so that the sealing rubber core 10 is installed in the inner cavity of the sealing base sleeve 9, and the sealing rubber core Two ends of 10 are installed with one or more sets of easy-change rubber pads 8 respectively; the hardness of the sealing base sleeve 9 is greater than that of the sealing rubber core 10 .

[0046] The middle part of the sealing base sleeve 9 of the present invention is in contact with the sealing rubber core 10, the inner ...

Embodiment 3

[0048] Embodiment 3, with reference to attached Figure 5 The difference between the present invention and Embodiment 1 is that the inlet 13.3 of the first through hole 13.1 does not need to be arranged on the lower outer wall of the rubber replacement cylinder 13, and the outlet does not need to be arranged on the top, and the first through hole does not need to 13.1 is arranged inside the outer wall of the rubber replacement cylinder 13 to reduce production costs; instead, the inlet 13.3 is arranged on the upper part of the outer wall of the rubber replacement cylinder 13, communicates with the outlet 13.4 of the inner wall, injects pressure through the inlet 13.3, and directly enters the air through the outlet 13.4 Cavity, so that the sealing cylinder 14 moves down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com