Pile driver for civil engineering

A technology of civil engineering and pile drivers, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems that the impact frequency and impact kinetic energy of pile drivers cannot be changed, and achieve the effect of prolonging the service life and working reliably and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further specifically described below through specific embodiments in conjunction with the accompanying drawings.

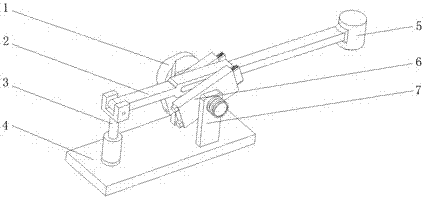

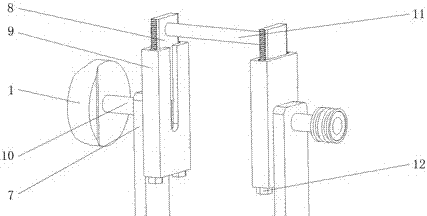

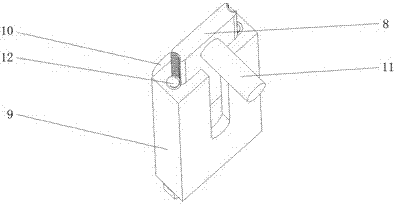

[0026] Such as figure 1 As shown, it is a structural diagram of a pile driver for civil engineering. The tail support rod 3 is fixed at the rear of the base 4. The tail support rod 3 includes a base, a hydraulic rod and a hinged joint. The hinged joint and the base are respectively located at both ends of the hydraulic rod. The seat is fixedly connected with the base 4, and the hinge joint is hinged with the end of the hammer rod 2. There is a thickened area in the middle of the hammer rod 2, and there is a hollow slot in the thickened area. The slot hole cooperates with the crankpin 11 of the crankshaft to form a sliding pair. The end is fixedly connected with the hammer head 5, the column 7 is fixedly installed on the front part of the base 4, the crankshaft 6 is installed on the column 7, one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com