Device for testing drilling performance of drilling tool for sampling deep layer of planet

A testing device and deep technology, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem of not completing the research of mechanical power structure and drilling regulations, formulating the comprehensive function of the scope, and the inability to achieve Problems such as simulating the deep sampling function of the planet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

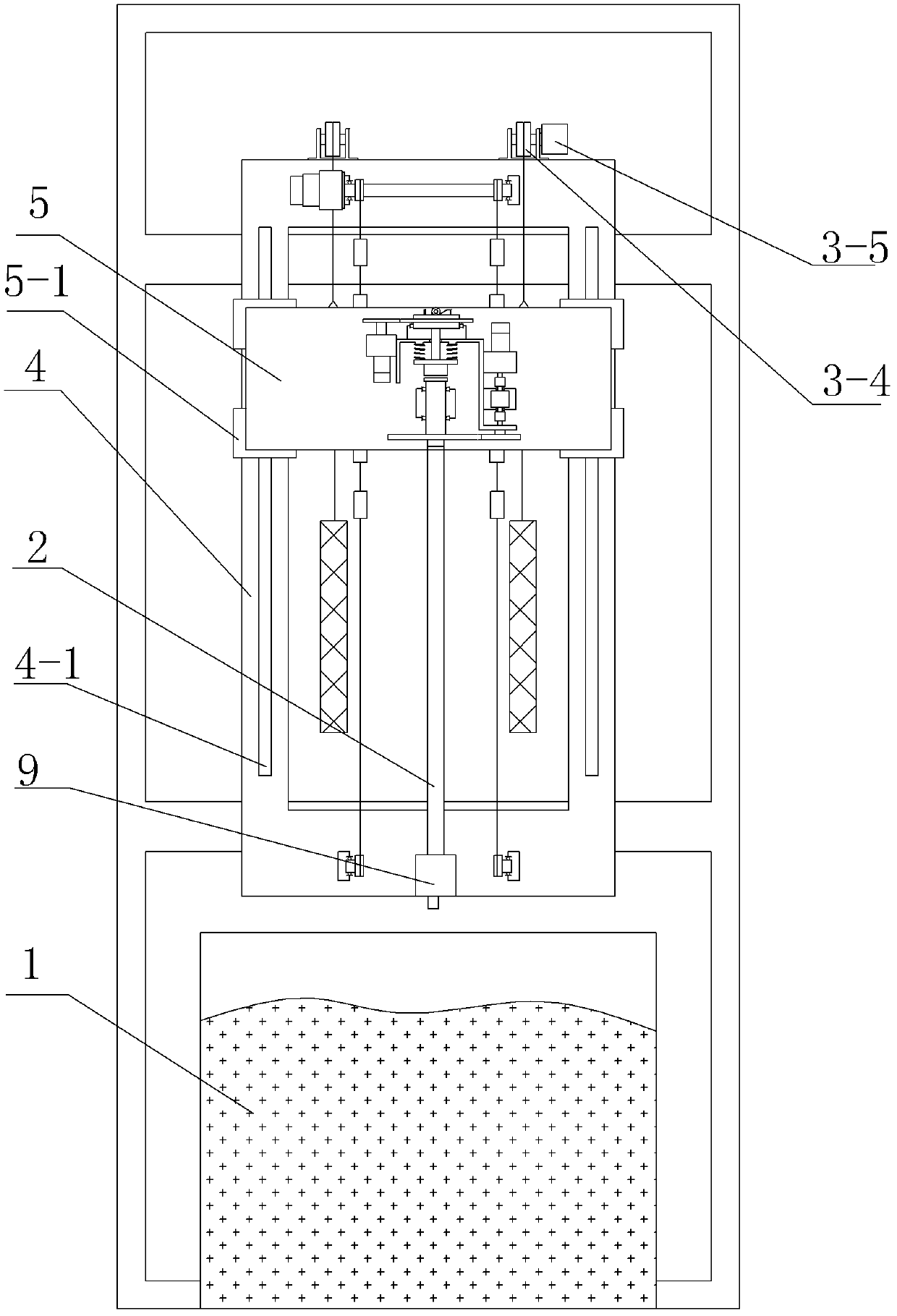

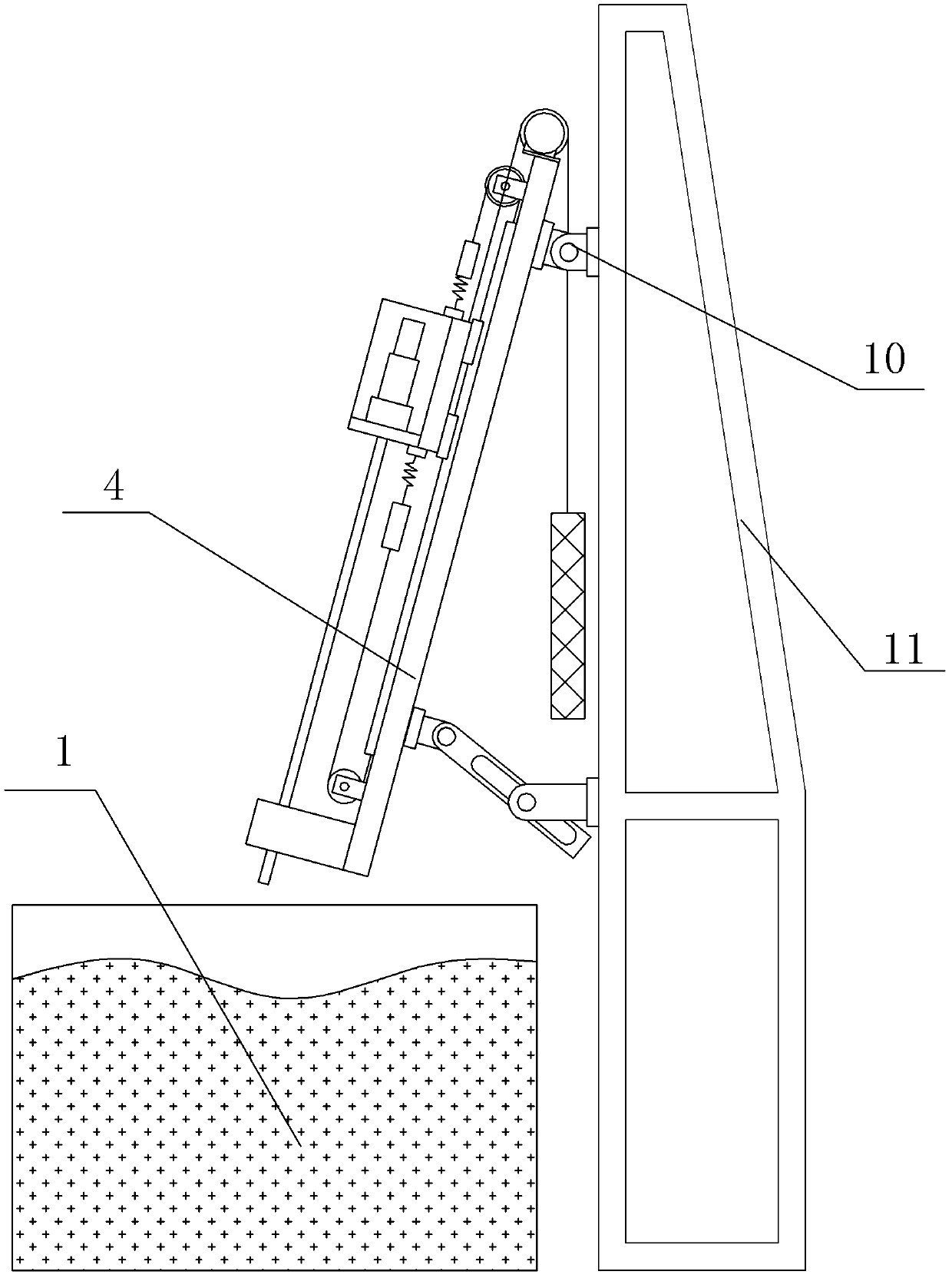

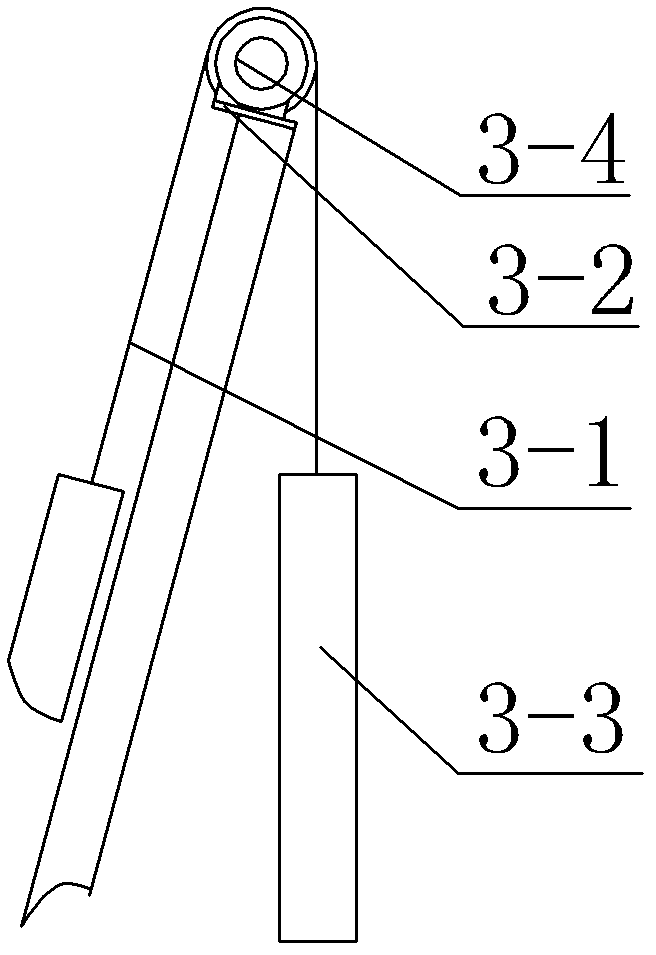

[0011] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the device of this embodiment comprises simulation star soil bucket 1, drill rod 2, angle adjustable mobile frame 4, mobile platform 5, impact drive mechanism, footage drive mechanism, rotary drive mechanism, drill rod support seat 9, Drilling angle adjustment mechanism 10, test bench 11 and two linear guide rails 4-1, impact drive mechanism includes a third code disc 6-1, impact motor 6-2, impact reducer 6-3, impact pinion 6- 4. Impact large gear 6-5, impact cam 6-6, impact drive housing 6-7, cam roller 6-8, spring 6-9, spring connection block 6-10 and heavy hammer 6-11, drive by footage The mechanism includes a first code disc 7-8, a footage motor 7-9, a footage reducer 7-10, a linkage shaft 7-11, two lower sprockets 7-1, two chains 7-3, and two pull-down force sensors 7-4. Two upper tension sensors 7-5 and two upper sprockets 7-6. The rotary drive mechanism includes a drill pipe m...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 7Describe the present embodiment, the drilling angle adjustment mechanism 10 of the present embodiment includes the angle adjustment tilt platform lower support 10-1, the angle adjustment tilt platform upper support 10-2, the upper rotation shaft 10-3, and the angle adjustment platform upper support 10-1. Support 10-4, lower rotating shaft 10-5, swing rod 10-6, angle adjustment bench lower support 10-7 and movable shaft 10-8, angle adjustment tilt table upper support 10-2 and angle adjustment tilt The lower support 10-1 is fixed on the angle adjustable mobile frame 4, the upper support 10-4 of the angle adjustment bench and the lower support 10-7 of the angle adjustment bench are fixed on the test bench 11, and the angle adjustment The upper support 10-2 of the tilting platform is hinged with the upper support 10-4 of the angle adjustment platform through the upper rotating shaft 10-3, and one end of the swing rod 10...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 Describe this embodiment, the device of this embodiment also includes four moving sliders 5-1, and the moving bottom plate 5 slides through the four moving sliders 5-1 and the two linear guide rails 4-1 on the angle-adjustable moving frame 4 connect. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com