Assembly type corrugated steel arch-shaped shed-tunnel structure

A technology of corrugated steel and arched sheds, applied in construction, protective equipment, etc., can solve the problems of poor bearing capacity and impact resistance of falling rocks, serious environmental damage, poor adaptability to deformation, etc., to achieve improved mechanical performance and significant Economic benefits and the effect of reducing the pressure on traffic protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

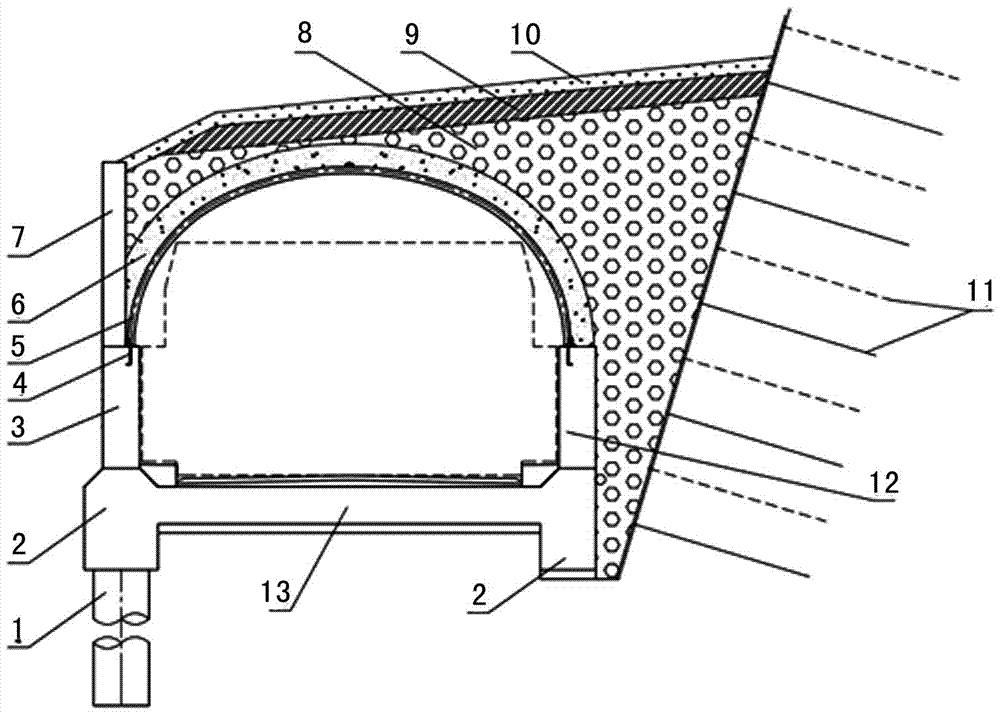

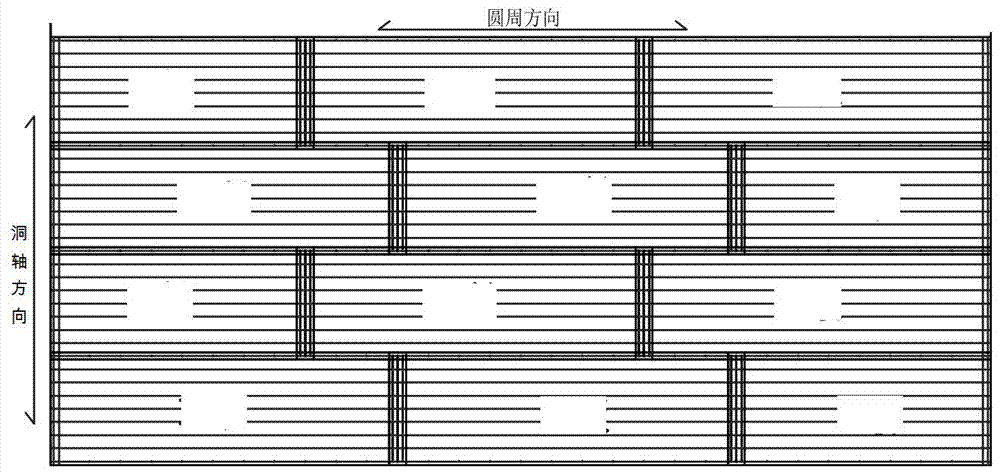

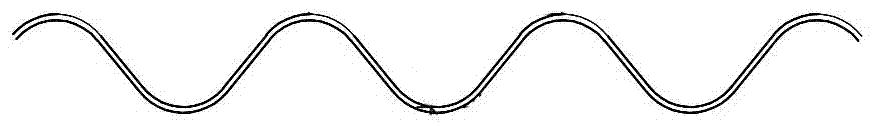

[0016] As shown in the figure, a prefabricated corrugated steel arched shed structure disclosed in the present invention is provided with a reinforced concrete foundation rigidly integrated with the inner and outer sides at the lower part, reinforced concrete side walls are arranged on the inner and outer sides, and reinforced concrete side walls are arranged on the outer side. There is an outer reinforced concrete retaining wall 7, the upper end face of the inner and outer reinforced concrete side walls is equipped with a corrugated steel plate arched ceiling 5 along the axial direction of the hole, and the arched outer side of the steel plate arched ceiling 5 is laid with fillers accordingly. and greenery. The lower reinforced concrete foundation is a rigid body formed by connecting the underground pile foundation 1, the underground continuous beam 2 in the form of a strip foundation, and the reinforced concrete bottom plate 13 to each other. The reinforced concrete outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com