Dye liquor for low-temperature black polyester elastic knitted fabric and dyeing technology

A knitted fabric, black technology, applied in the field of fabric production, can solve the problems of high production cost, unsatisfactory, loose, etc., and achieve the effect of improving factory efficiency, saving production cost, and permanent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A low-temperature black full polyester elastic knitted fabric dye liquor, the dye liquor structure includes dye components and dye auxiliary components, the dye components are cationic dyes, including 0.30% o.w.f cationic red SD-GRL, 2.0% o.w.f cationic black AD -RN, 0.3% o.w.f cationic yellow SD-5GL; dye auxiliaries include 0.3g / L pure glacial acetic acid HAc, 0.3g / L sodium acetate, 0.3g / L dispersing and leveling agent HTN, 1.0g / L Yuzhongbao HB226 , 0.3g / L chelating diffuser DM1016.

[0018] A low-temperature dyeing process for black all-polyester elastic knitted fabrics, using the above-mentioned dye solution, adding all-polyester gray cloth into a dye vat with a bath ratio of 1:5-10, heating the dye vat to 35°C for pre-treatment, and then adding the above-mentioned cationic dyes, The temperature was raised to 80°C for low-temperature dyeing for 30 minutes, followed by water washing and dehydration, and the temperature was controlled at 40°C for low-temperature settin...

Embodiment 2

[0020] A kind of dye liquor of low-temperature black full polyester elastic knitted fabric, the dye liquor structure includes dye components and dye auxiliary components, the dye components are cationic dyes, including 0.30% o.w.f cationic red SD-GRL, 2.0% o.w.f cationic Black AD-RN, cationic yellow SD-5GL at 0.3% o.w.f; dye auxiliaries include 0.3g / L pure glacial acetic acid HAc, 0.3g / L sodium acetate, 0.3g / L dispersing and leveling agent HTN, 1.0g / L bath Zhongbao HB226, 0.3g / L chelating diffuser DM1016.

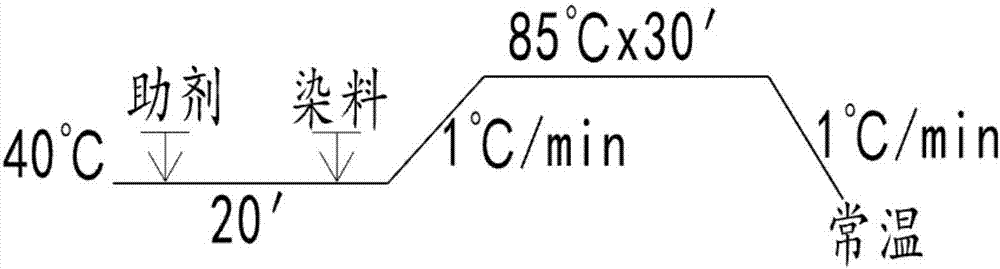

[0021] A low-temperature dyeing process for black all-polyester elastic knitted fabrics, using the above-mentioned dye solution, adding all-polyester gray cloth into a dye vat with a liquor ratio of 1:5-10, heating the dye vat to 38°C for pre-treatment, and then adding the above-mentioned cationic dyes, The temperature was raised to 85°C for low-temperature dyeing. The dyeing time was 35 minutes, followed by water washing and dehydration. The temperature was controlled at 4...

Embodiment 3

[0023] A kind of dye liquor of low-temperature black full polyester elastic knitted fabric, the dye liquor structure includes dye components and dye auxiliary components, the dye components are cationic dyes, including 0.30% o.w.f cationic red SD-GRL, 2.0% o.w.f cationic Black AD-RN, cationic yellow SD-5GL at 0.3% o.w.f; dye auxiliaries include 0.3g / L pure glacial acetic acid HAc, 0.3g / L sodium acetate, 0.3g / L dispersing and leveling agent HTN, 1.0g / L bath Zhongbao HB226, 0.3g / L chelating diffuser DM1016.

[0024] A low-temperature dyeing process for black all-polyester elastic knitted fabrics, using the above-mentioned dye solution, adding all-polyester gray cloth into a dye vat with a bath ratio of 1:5-10, heating the dye vat to 40°C for pre-treatment, and then adding the above-mentioned cationic dyes, The temperature was raised to 100°C for low-temperature dyeing. The dyeing time was 40 minutes, followed by water washing and dehydration. The temperature was controlled at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com