Automatic cable rolling mechanism for new energy automobile charging pile

A new energy vehicle and winding mechanism technology, applied in the direction of electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of excessive space occupation, loose cable winding, knotting, etc., and achieve low processing accuracy, The effect of compact cable winding and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

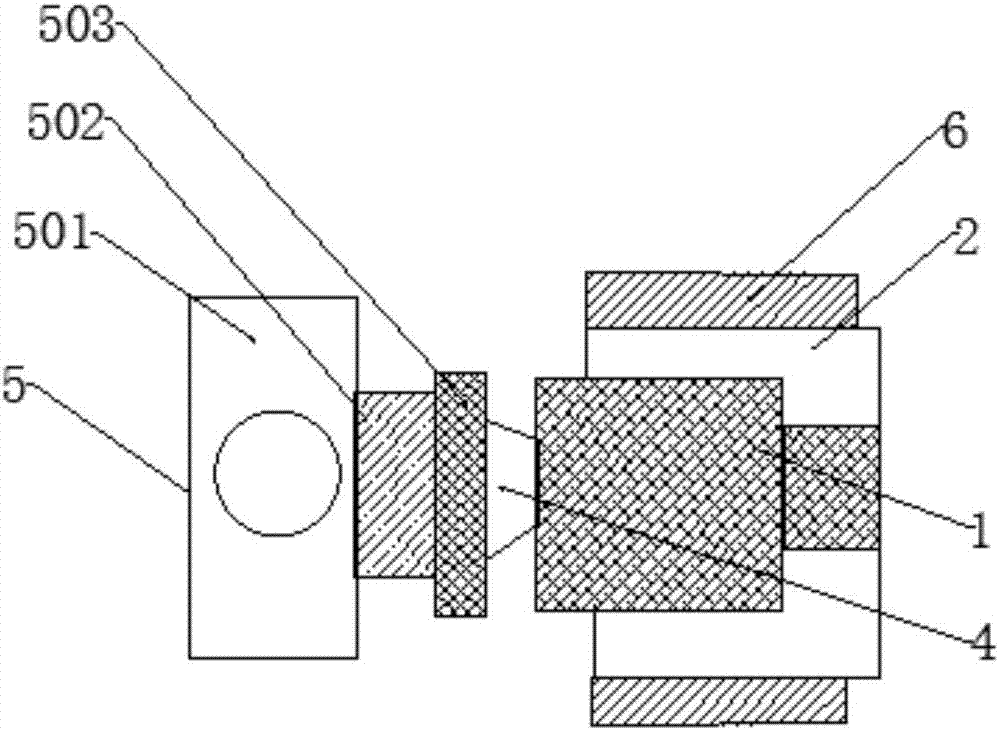

[0028] Such as figure 1 and Figure 4 As shown, the present invention provides a cable automatic winding mechanism for a new energy vehicle charging pile, including a winding shaft 1, the outer surface of the winding shaft 1 is sleeved with a bobbin 2, and the winding bobbin 2 A winding groove 3 is dug on the surface, and the inner diameter of the winding groove 3 is consistent with the outer diameter of the cable to be wound; the end of the reel of the winding shaft 1 is sleeved with a coupling gear 4, and The other end is sleeved with a two-way transmission mechanism 5; the rewinding shaft 1 is connected to the two-way transmission mechanism 5 through the coupling gear 4. When the two-way transmission mechanism 5 starts to work, it drives the rewinding shaft 1 to rotate, and the cable is connected with the rotation when rotating. The cable is clamped inside the winding groove 3, so as to realize the automatic winding operation of the cable.

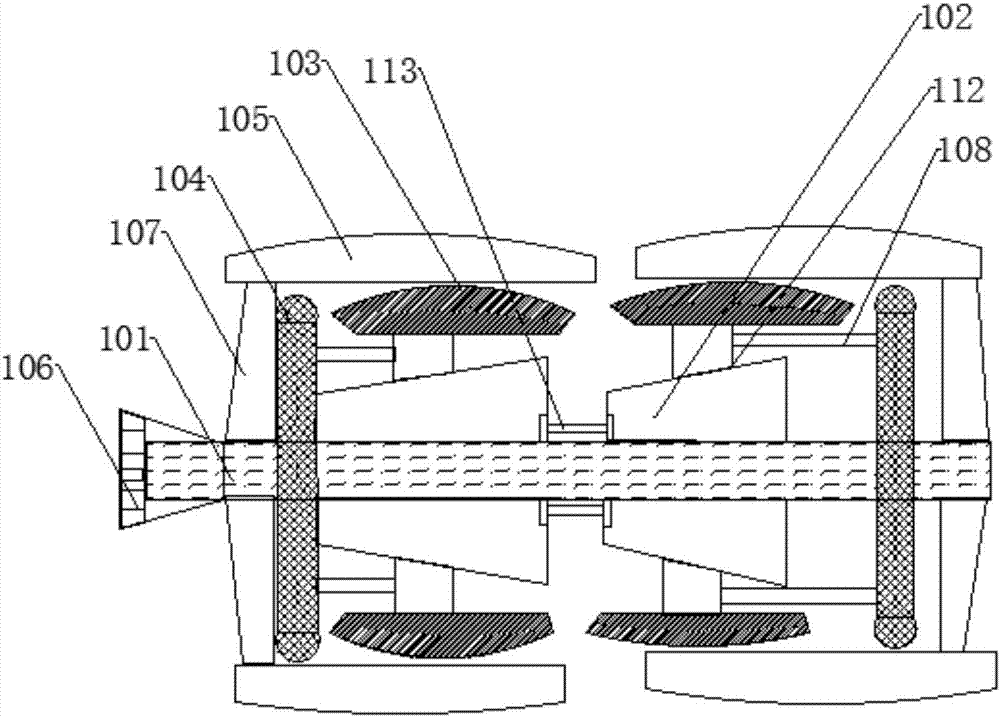

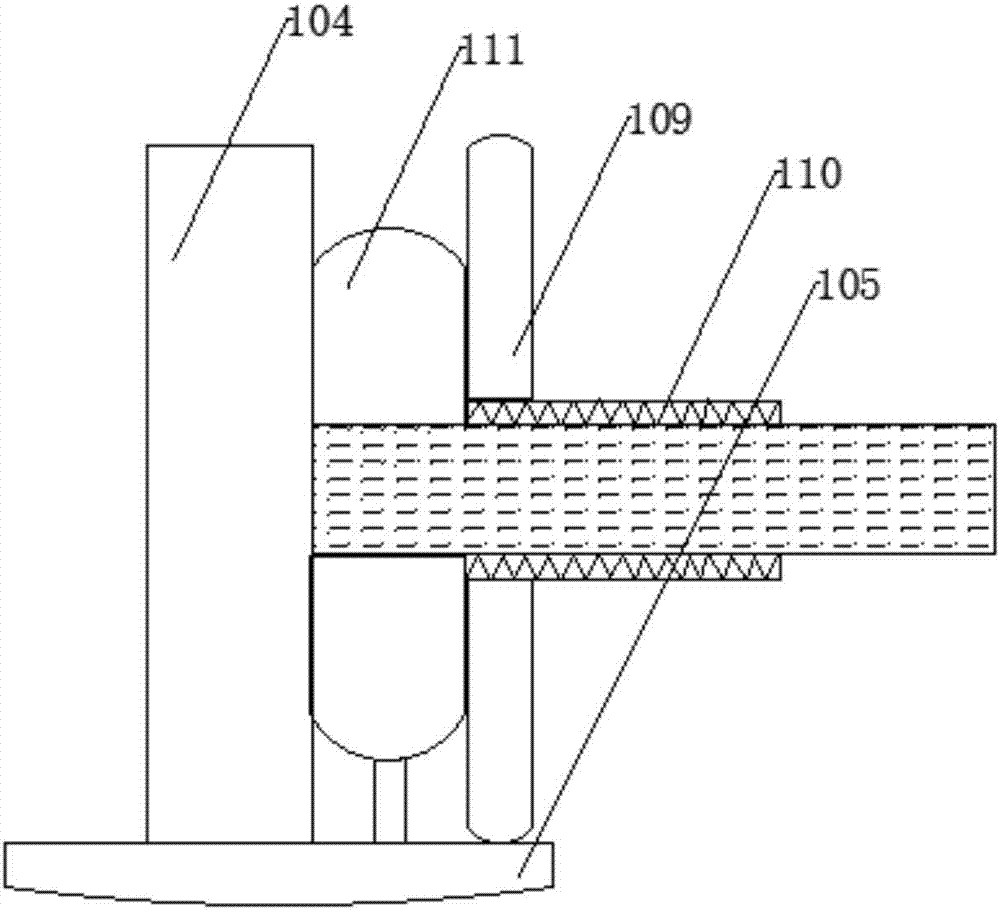

[0029] Such as figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com