Transmission device with posture adjustment function

A transmission device and attitude technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low efficiency and slow response, and achieve the effect of high efficiency, fast response, and prevention of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

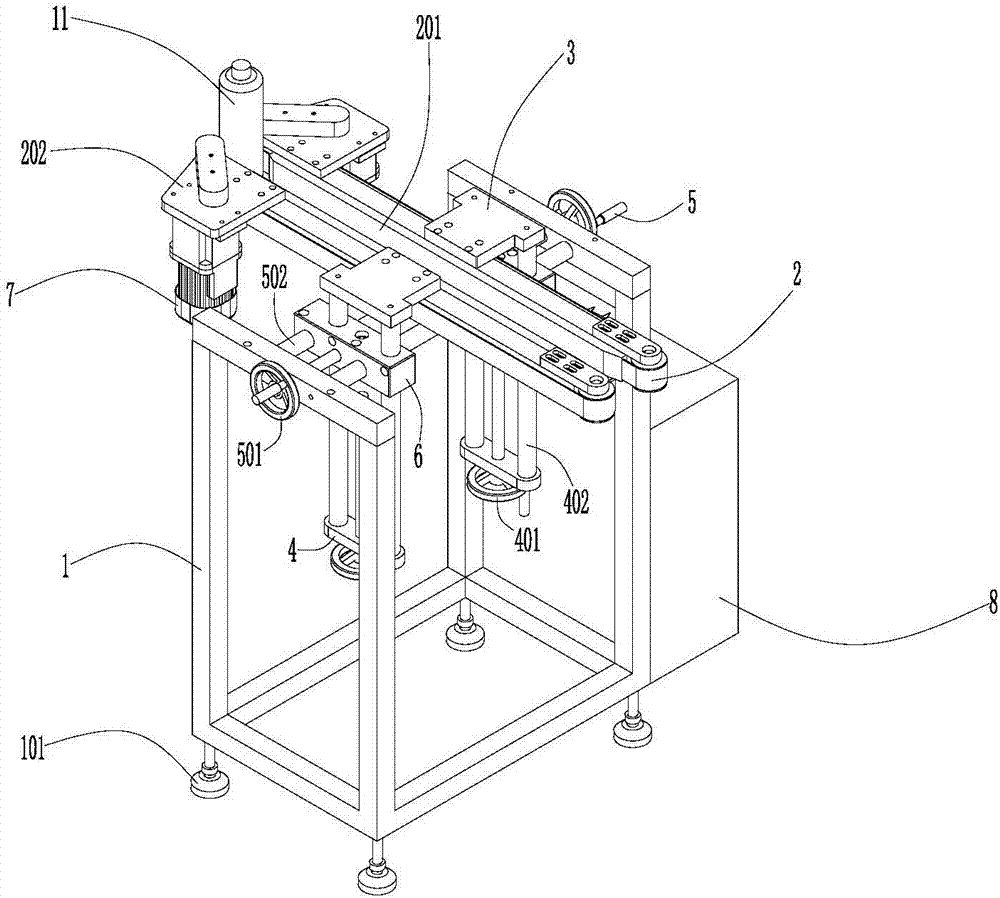

[0035] This embodiment provides a transmission device with posture adjustment function, such as figure 1 As shown, it includes a support frame 1, an attitude adjustment mechanism 2, an adjustment mechanism 3, a vertical displacement mechanism 4, a horizontal displacement mechanism 5, a fixing member 6, a drive motor 7, a visual detection mechanism (not shown in the figure) and an electric box 8 .

[0036] Wherein, four supporting bases 101 are provided at the bottom of the supporting frame 1 .

[0037] The attitude adjustment mechanism 2 is located on the support frame 1; the attitude adjustment mechanism 2 includes two conveyor belts 201, and the belt surfaces of the conveyor belts 201 are vertically arranged; the two conveyor belts 201 are arranged oppositely; There is a limit plate 202 for keeping the workpiece 11 vertical; the position of the limit plate 202 can be adaptively adjusted according to the size of the workpiece 11; the workpiece 11 is cylindrical, and it is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com