Full-automatic continuous reinforcement flow separation and packing device and packing method thereof

A splitting device and fully automatic technology, applied in the field of steel bar manufacturing, can solve the problems of continuous packaging without stopping the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

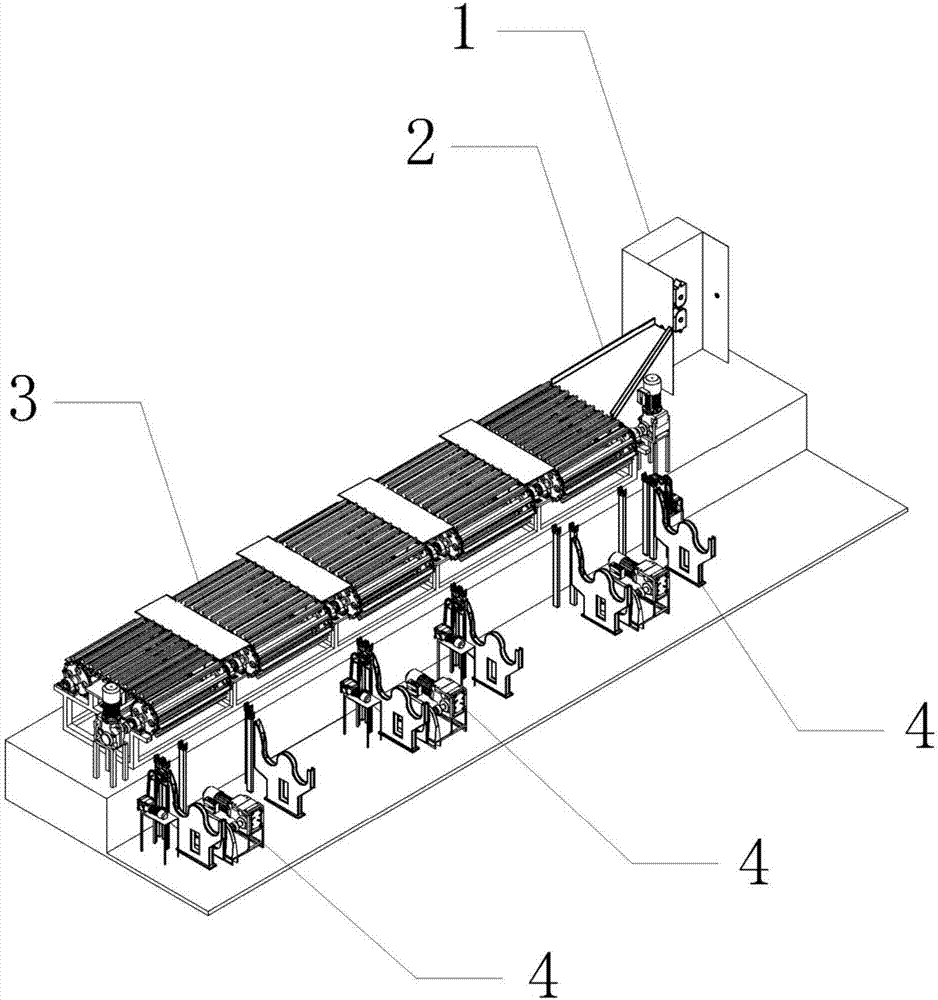

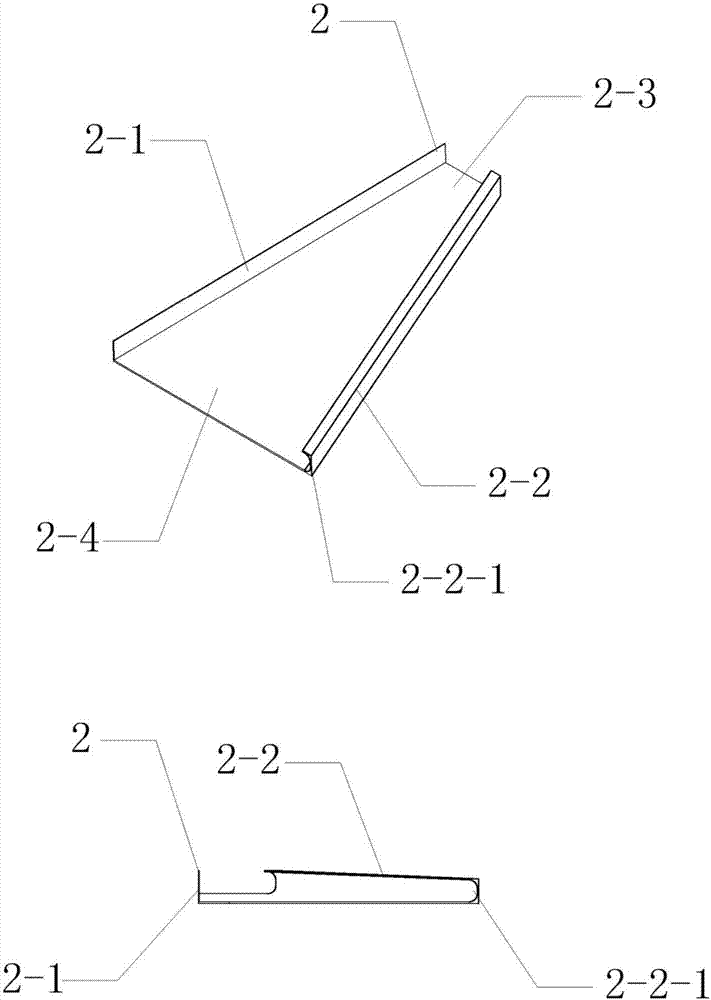

[0044]The present invention will be described in detail below with reference to the accompanying drawings and the embodiments thereof, but the protection scope of the present invention is not limited to the scope described in the embodiments.

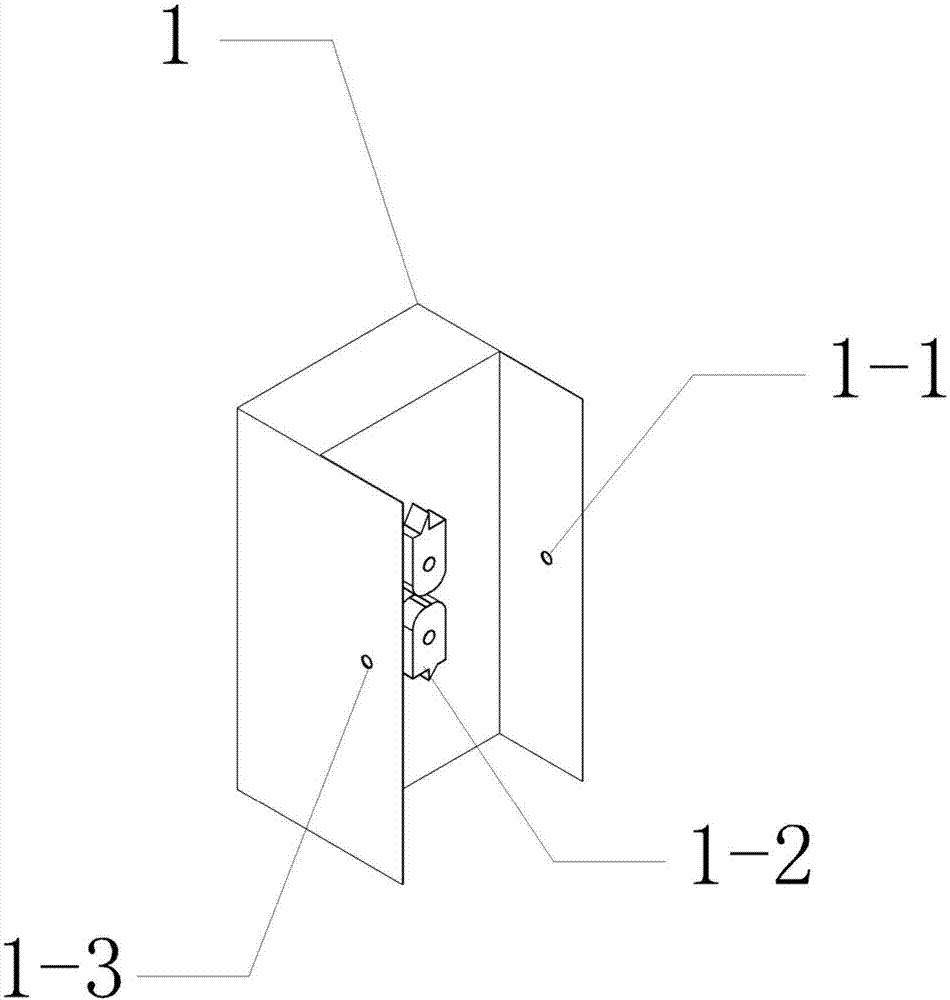

[0045] The steel bar shearing machine 1 of the present invention refers to: the main components of the steel bar shunting and packaging device; and a steel bar inlet 1-1, a steel bar shearing knife 1-2, and a steel bar outlet 1-3 are arranged on it; its function is It is convenient to cut out the required steel bars; its structure is as attached figure 2 shown; its design position is as attached figure 1 Shown in mark 1.

[0046] The steel bar inlet 1-1 of the present invention refers to: be located at the circular hole on the right side of steel bar shearing machine 1; Its effect is to facilitate steel bar to enter steel bar shearing machine 1; Its design position is as attached figure 1 Shown in Mark 1-1.

[0047] The steel bar sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com