Heat exchanger core binding machine

A technology of heat exchanger and strapping machine, which is applied to the parts of strapping machinery and strapping materials, etc. It can solve the problems of difficult control of multi-channel strapping strength, low strapping efficiency, high labor intensity, etc., and achieves fast and convenient type change and saves energy. Good labor force and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

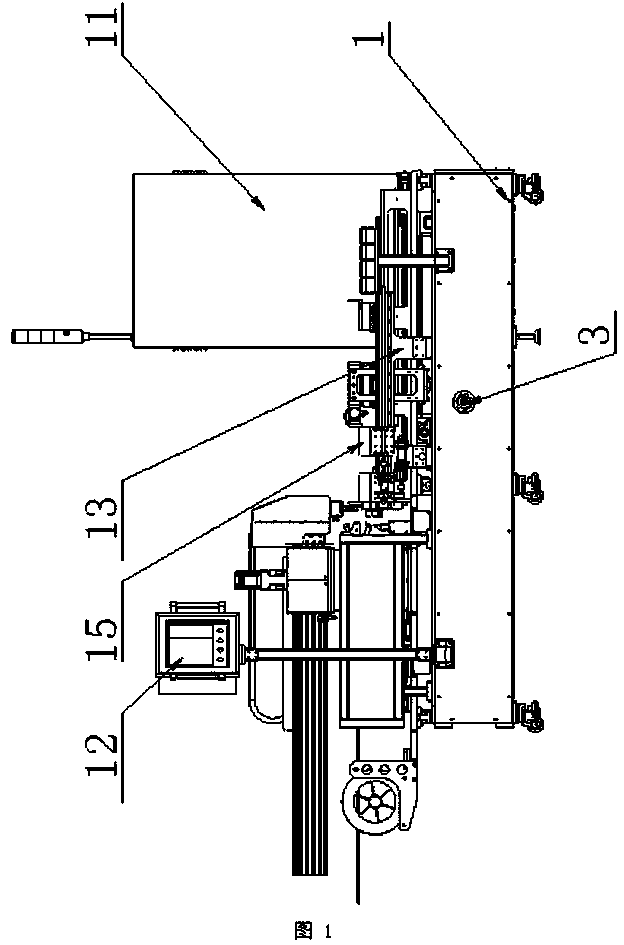

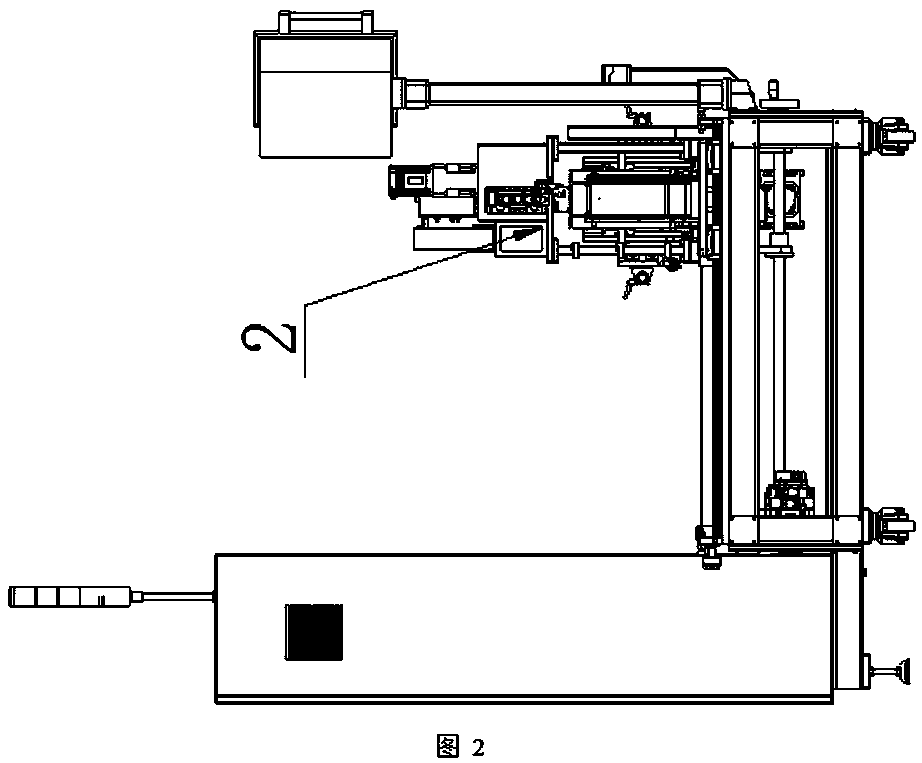

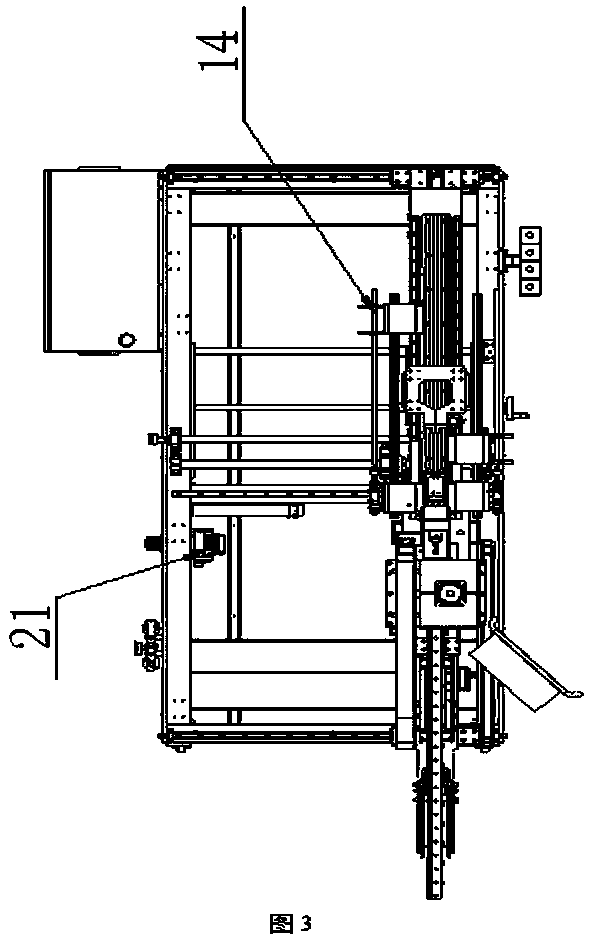

[0021] refer to Figure 1-4 , the specific embodiment adopts the following technical solutions: heat exchanger core body binding machine, including the chassis 1 and the main mechanism 2, the main mechanism 2 is arranged on the guide rail of the chassis 1, and the main mechanism 2 moves left and right through the screw rod and the main mechanism The motor 21 is connected; the underframe 1 is provided with a distribution box 11, a touch screen control box 12, a fixed core support plate 13, an adjustable core support plate 14 and a core clamping module 15, and the side wall of the underframe 1 Also be provided with handwheel 3, handwheel 3 links to each other with adjustable core body support plate 14 by screw mandrel, adjustable core body support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com