Single-color spraying and printing dual-purpose machine for terrace printing and work method thereof

A single-color, printing technology, applied in printing, typewriters, etc., can solve the problems of heavy workload and low efficiency, and achieve the effect of improved printing, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

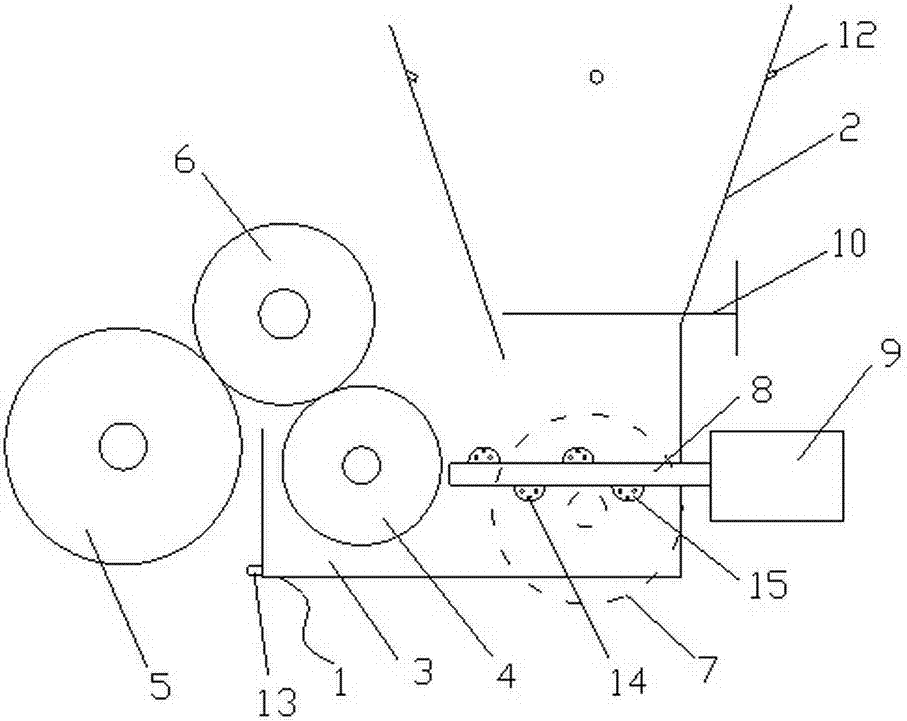

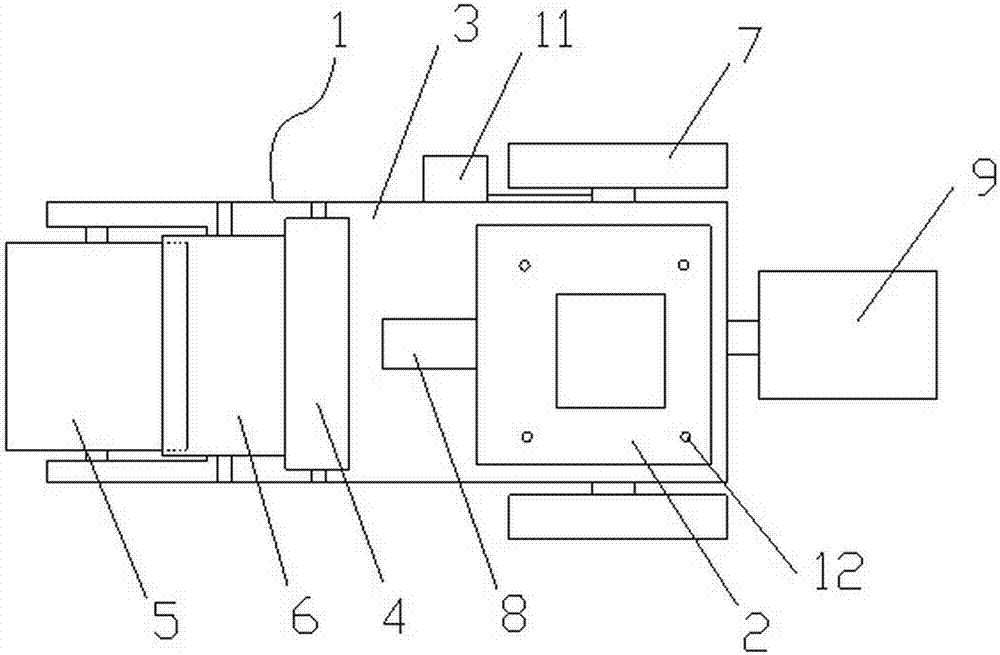

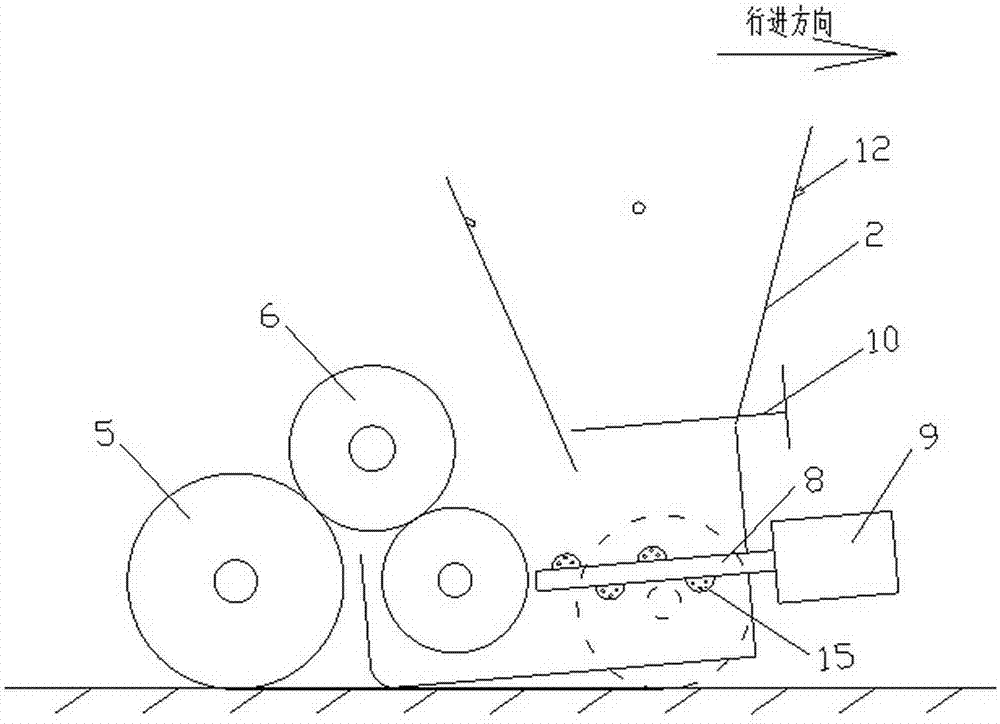

[0022] The monochromatic spraying and printing dual-purpose machine for floor printing of the present invention comprises a traveling vehicle frame 1 and a hopper 2 arranged on the traveling vehicle frame 1, the lower part of the hopper 2 is provided with a storage pool 3, and the storage pool 3 is provided with a transfer drum 4, the first end of the traveling frame 1 is provided with a transfer drum 5, and an intermediate drum 6 is provided between the transfer drum 4 and the transfer drum 5, and the traveling frame 1 The second end is provided with a road wheel 7, forming a support wheel that travels with the road wheel 7 and the transfer roller 4 as a road frame.

[0023] Further, in order to realize the stirring of the printing paint in the material storage tank 3, the above-mentioned material storage tank 3 is provided with a stirring shaft 8 protruding from the outside into the tank, and the outer end of the stirring shaft 8 is driven by a motor 9 to rotate.

[0024] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com