Composite material sandwich plate for floating body structure and floating body

A composite material and sandwich board technology, applied in the mechanical field, can solve the problems of poor anti-corrosion performance, high density, high cost, etc., and achieve the effects of avoiding corrosion, easy cutting and processing, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In view of the deficiencies in the prior art, the inventor of the present application was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

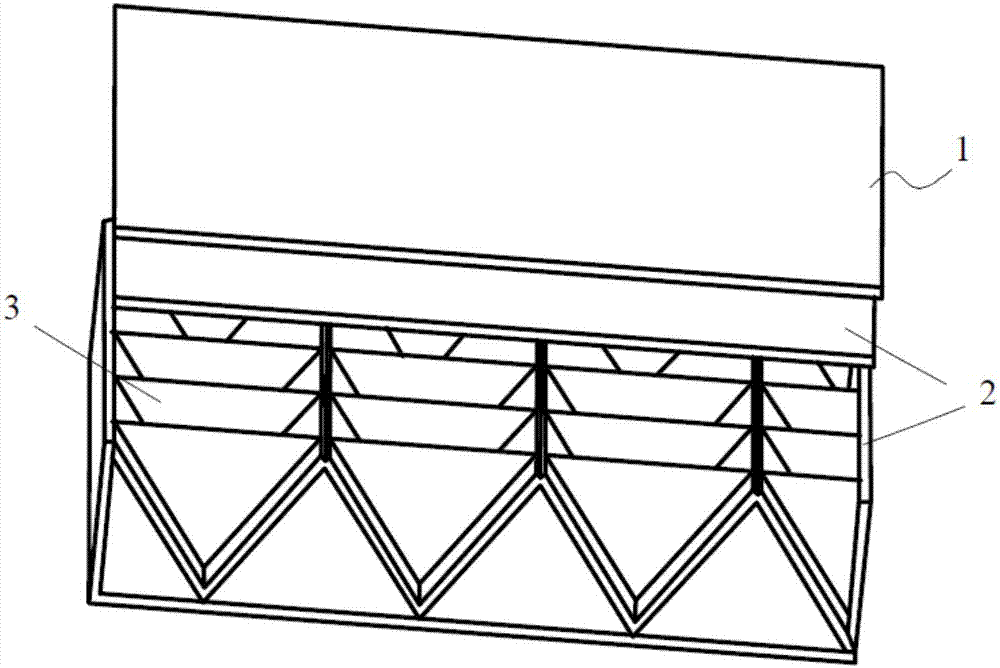

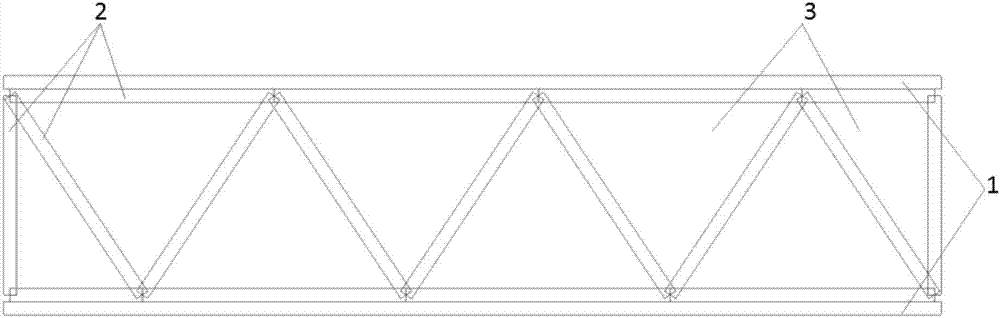

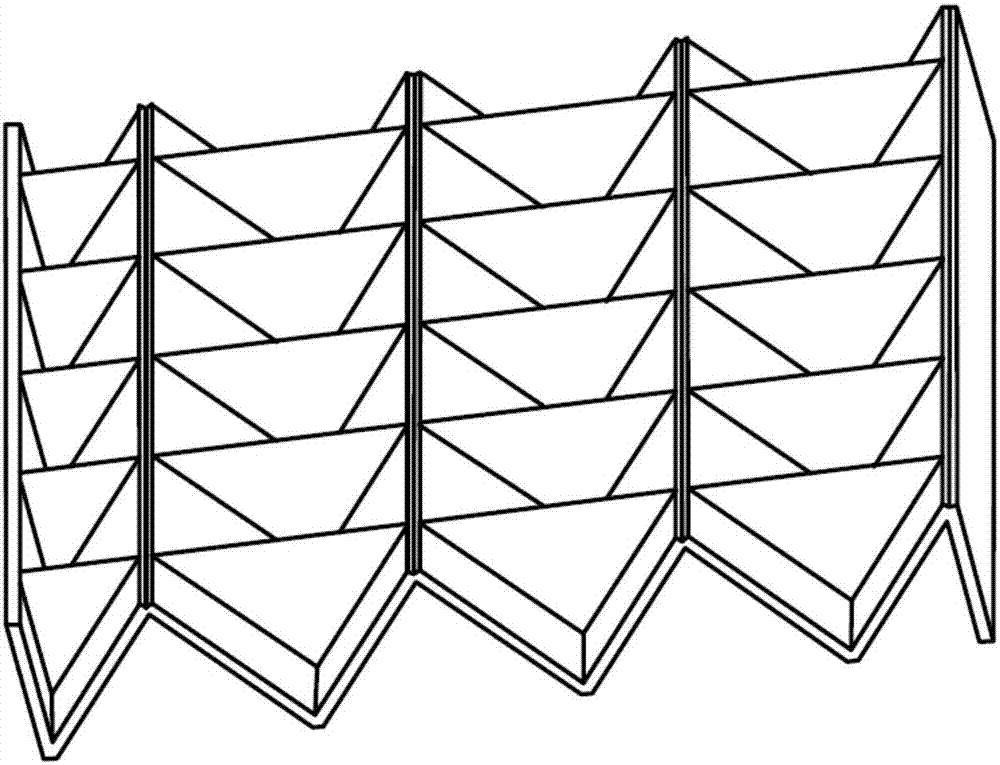

[0030] An embodiment of the present invention provides a composite sandwich panel for a floating body structure, including a first high alkali-resistant glass fiber cloth layer, a second high alkali-resistant glass fiber cloth layer and a core layer, the first high alkali-resistant glass fiber cloth layer. The fiber cloth layer is fixedly arranged on the upper surface of the core layer, and the second high alkali-resistant glass fiber cloth layer is fixedly arranged on the lower surface of the core layer; the core layer has a plurality of cavities inside, and the hollow The cavity is filled with lightweight plastic foam.

[0031] Further, the core layer includes a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com