Automatic sorting equipment for special-shaped sheet parts

An automatic sorting and sheet technology, applied in sorting and other directions, can solve the problems of automatic feeding upside down, stacking, etc., and achieve the effect of high-speed handling, promotion of development, and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

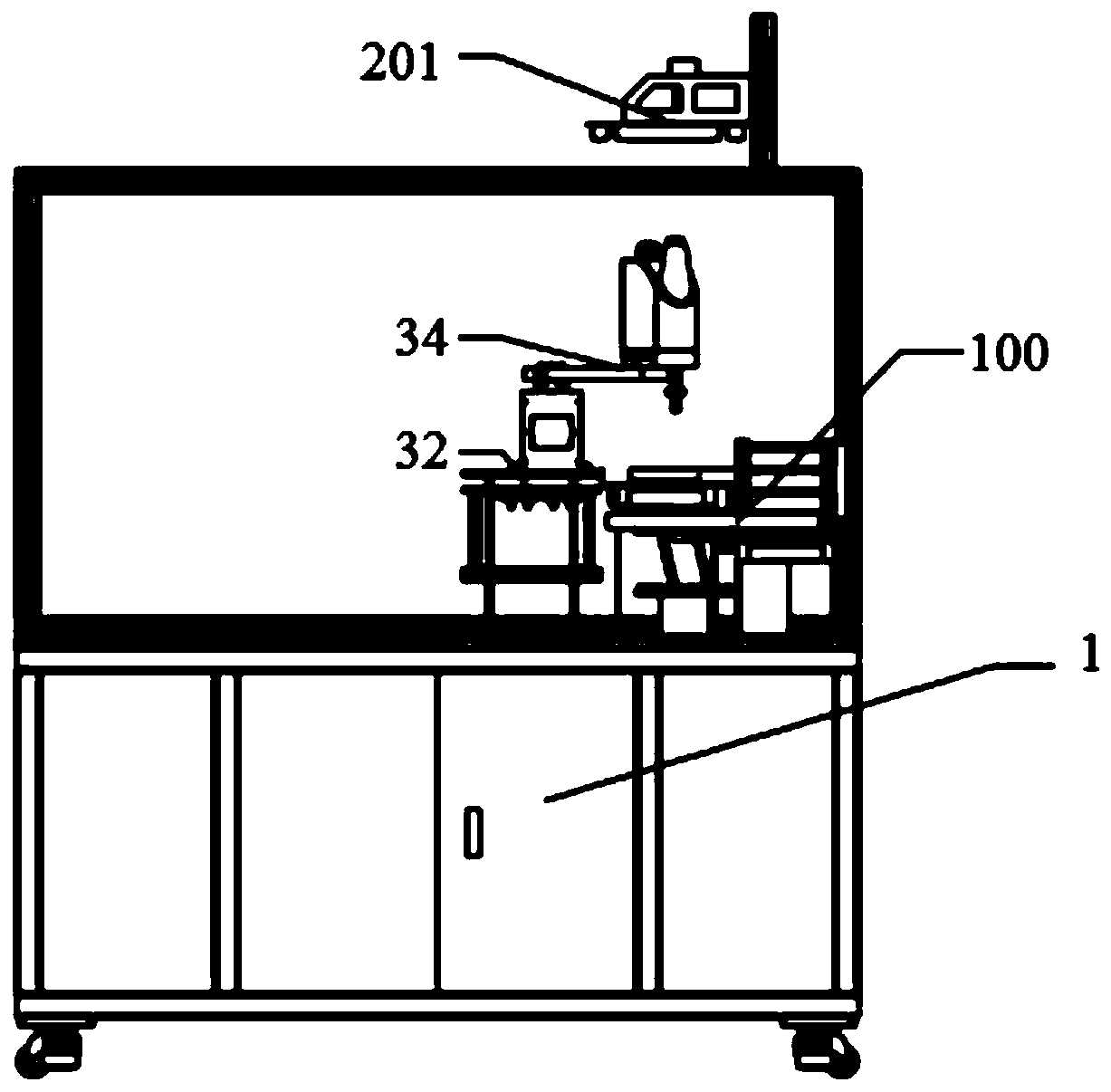

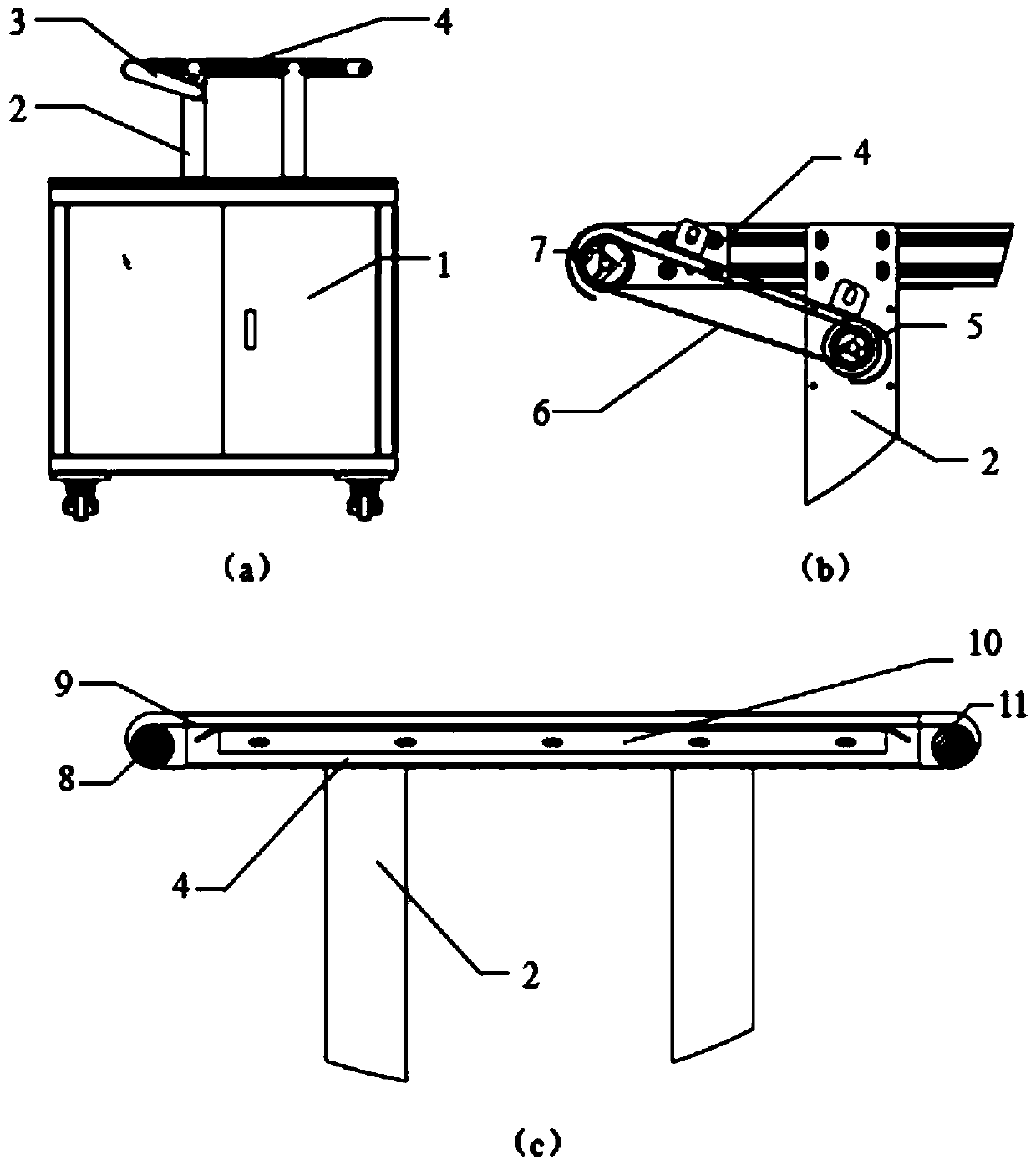

[0049] Such as Figure 1 to Figure 10 As shown, the present invention discloses an automatic sorting device for special-shaped sheet parts, including a circular feeding system 100 , a positioning platform 32 , a robot 34 and a vision system 201 . Preferably, the robot 34 of the present invention is a planar four-degree-of-freedom robot. Of course, the robot 34 can also choose a planar six-degree-of-freedom robot or other types of robots, as long as the functions in the present invention can be realized, they will not deviate from the concept of the present invention.

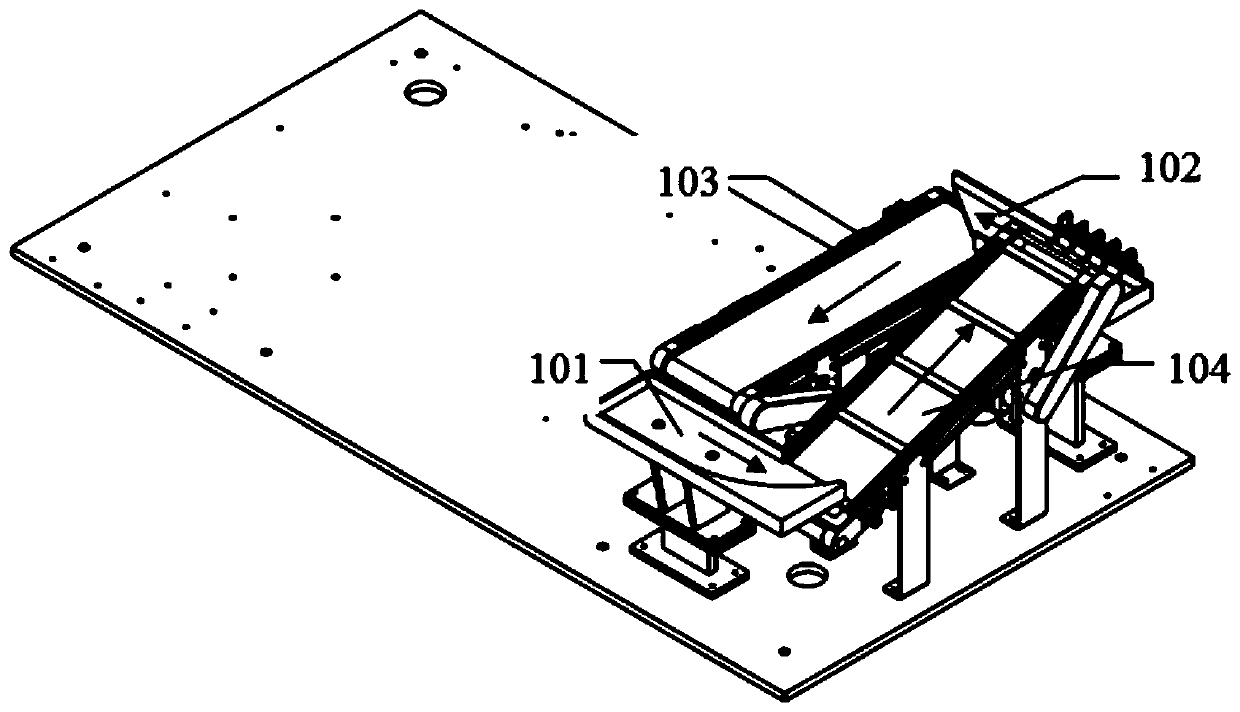

[0050] Such as figure 2 As shown, the circulating feeding system 100 includes a feeding device 103 , a feeding device 104 , a first vibrating device 101 , and a second vibrating device 102 . Preferably, the first vibration device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com