Novel cloud ladder fire-fighting robot

A technology of fire-fighting robots and ladders, applied in the field of robots, can solve the problems of limited fire-fighting range, inability to adjust the head, and inability to effectively rescue, and achieve the effects of wide fire-fighting range, low resistance, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

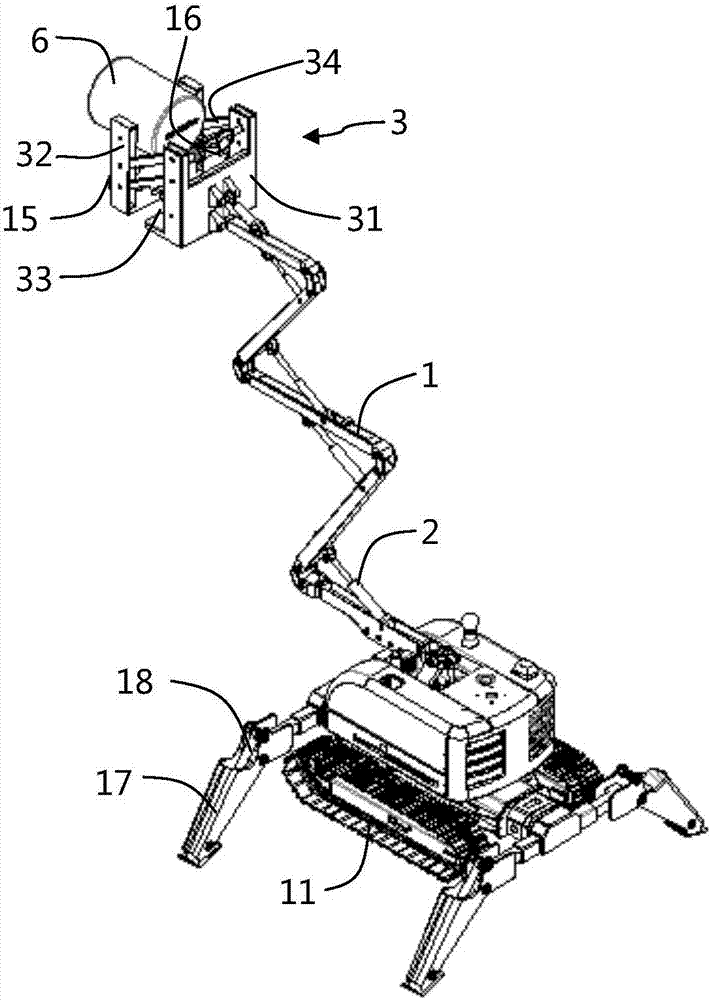

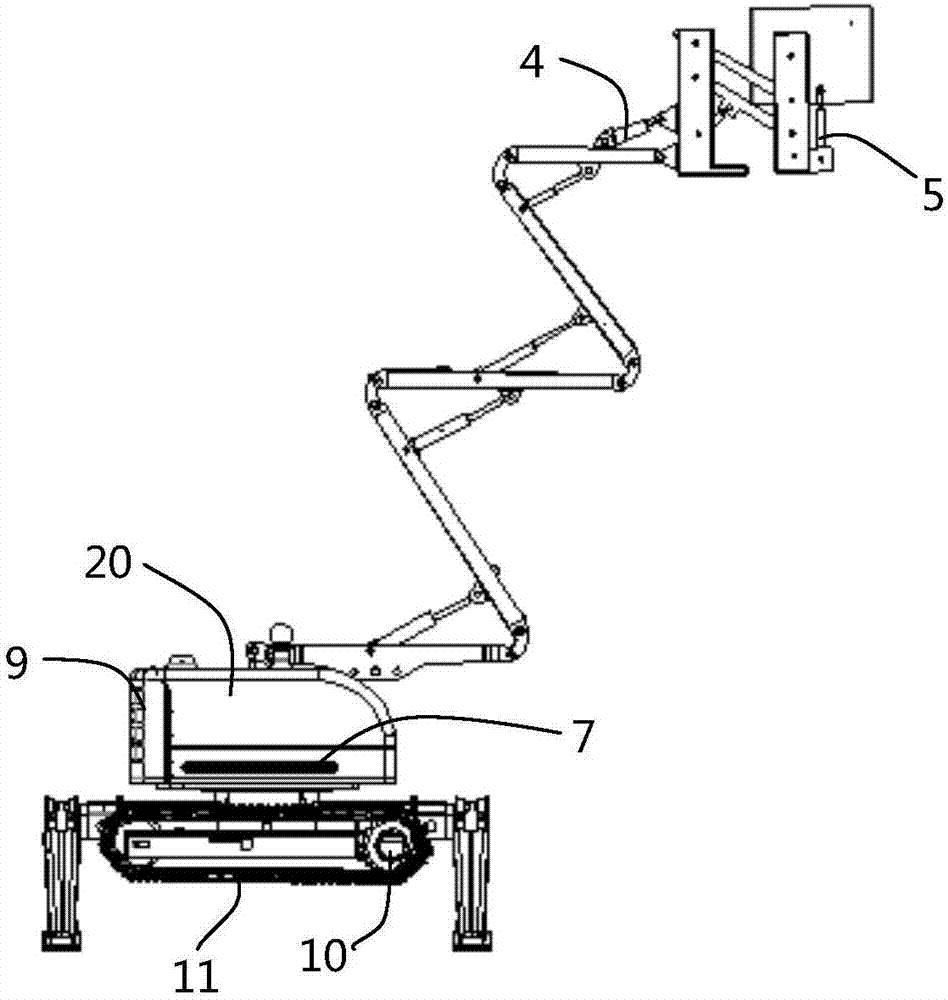

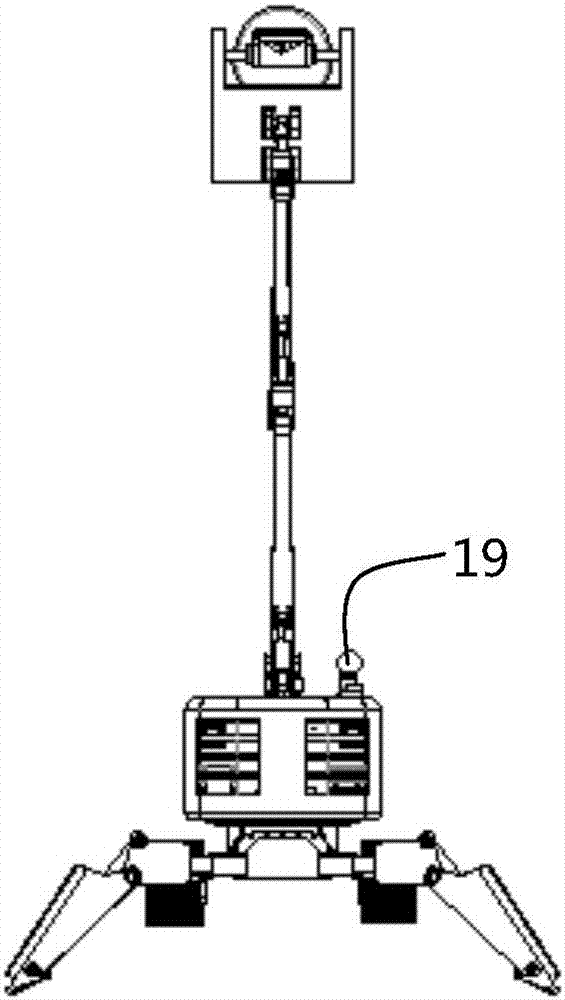

[0039] Such as Figure 1 to Figure 5 As shown, the novel aerial ladder fire-fighting robot of the present embodiment comprises a control box 20, an aerial ladder lifting mechanism, a slewing mechanism, a traveling mechanism and a bearing mechanism, and the control box 20 is provided with an alarm flashing light 19; Oil cylinder 2, bracket 3, swing oil cylinder 4, jacking oil cylinder 5 and high-pressure water cannon 6, the slewing mechanism includes a slewing bearing 7, the traveling mechanism includes a chassis 8, a diesel engine 9, a sprocket 10 and a crawler belt 11, and the slewing bearing 7 is fixed on the chassis 8, the diesel engine 9 and the control box 20 are all fixed on the chassis 8, and the crawler belt 11 is wound on the sprocket 10; the lifting arm 1 is fixed with the slewing bearing 7 through the adjustment mechanism, and the lifting cylinder 2 is fixed on the lifting arm 1. The frame 3 is hinged with the head of the lifting arm 1, the cylinder body of the swin...

Embodiment 2

[0055] In the novel aerial ladder fire-fighting robot of this embodiment, the component mass percentages of the lifting arm are: C: 0.19%, Mn: 0.59%, Si: 0.25%, Co: 0.5%, Cr: 1.4%, V: 1.13%, Ni: 1.02%, S: 0.020%, P: 0.020%, and the balance is Fe; the blank of the lifting arm goes through the first stage: room temperature to 560°C: the blank is heated from room temperature to 560°C, and the heating time is 60min; the second stage: 560°C~780°C: Heat the billet from 560°C to 780°C, control the heating time for 20 minutes, and keep it for 80 minutes; the third stage: 780°C~1200°C: heat the billet from 780°C to 1200°C, control the heating time for 70 minutes , heat preservation for 45 minutes; the fourth stage: 1200 ℃ ~ 1350 ℃: heating the billet from 1200 ℃ to 1350 ℃, controlling the heating time to 20 minutes, and heat preservation for 40 minutes. After heat treatment, there are almost no cracks inside the blank, and the body structure is dense;

[0056] As we all know, during th...

Embodiment 3

[0059] In the new ladder fire-fighting robot of this embodiment, the components of the lifting arm are weighed and mixed according to the mass percentage, wherein the mass percentage of the components is: C: 0.20%, Mn: 0.75%, Si: 0.35%, Co: 0.6 %, Cr: 1.47%, V: 1.03%, Ni: 1.22%, S: 0.020%, P: 0.020%, and the balance is Fe; the blank of the arm or forearm goes through the first stage: room temperature to 560°C: put The blank is heated from room temperature to 560°C, and the heating time is 45min; the second stage: 560°C to 780°C: the blank is heated from 560°C to 780°C, the heating time is controlled to 20min, and the heating time is 65min; the third stage: 780°C to 1200 ℃: Heat the billet from 780°C to 1200°C, control the heating time to 65min, and keep it warm for 40min; the fourth stage: 1200°C to 1350°C: heat the billet from 1200°C to 1350°C, control the heating time to 20min, keep it warm for 40min, After heat treatment, there are almost no cracks inside the blank, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com