Multi-tool approximation method for machining small-sized addendum fillets with worm grinding wheel

A worm grinding wheel, small size technology, applied in geometric CAD, special data processing applications, etc., can solve the problem of worm grinding wheel not being able to dress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

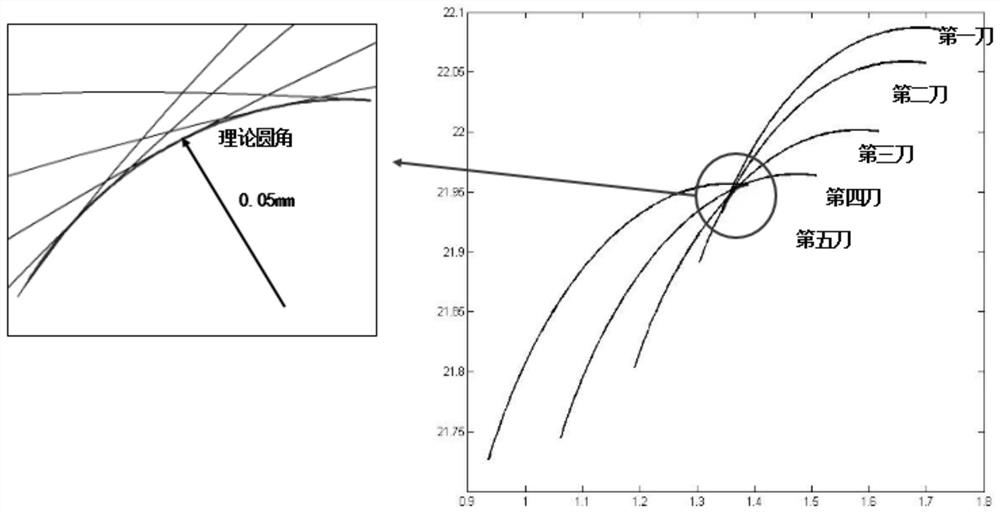

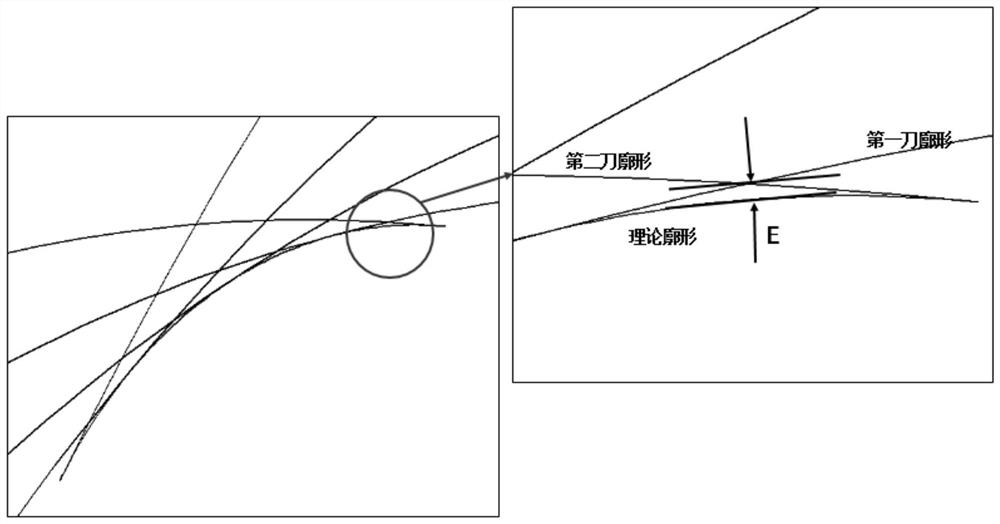

[0020] The multi-tool approximation method for machining the small fillet of the tooth top with the worm grinding wheel, the approximation principle is as follows figure 1 As shown, first determine the rack point vector of the large fillet on the processing tooth top, the radius of the large fillet is R, and the large fillet equation (X 1 , Y 1 )for:

[0021]

[0022] Large fillet tooth profile normal vector (N x , N y )for:

[0023]

[0024] where: R a Indicates the radius of the addendum circle, α is the solution parameter of the coordinates of the center of the circle, θ1 indicates the arc angle on the addendum circle, and θ2 indicates the arc angle on the involute line of the tooth profile. Substitute into the meshing equation:

[0025]

[0026] in represents the tooth profile normal vector, Indicates the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com