MC (Methyl Cellulose) colorful co-extrusion material drying device

A drying device and color technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of poor drying effect, short wind blowing stroke, poor drying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

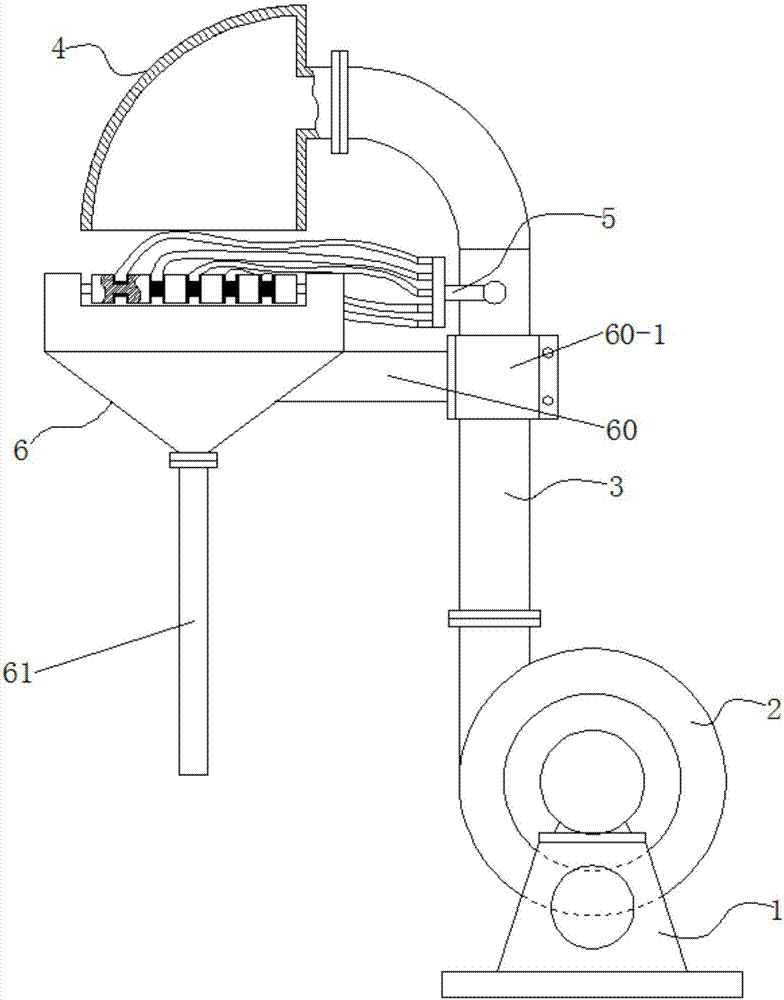

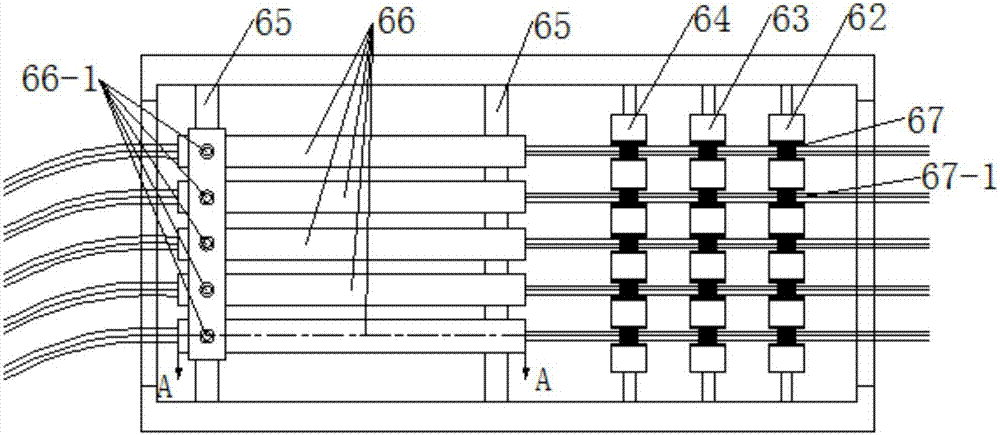

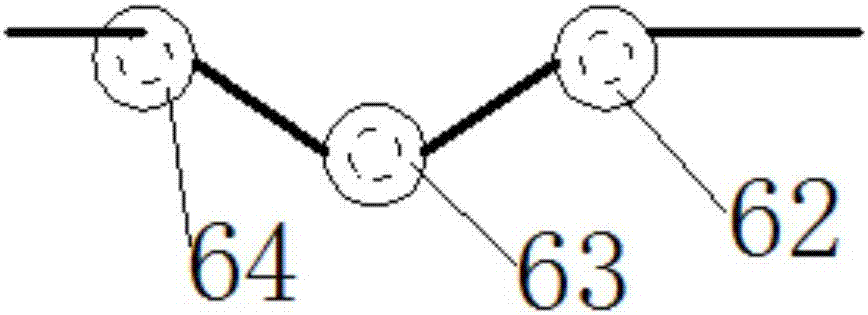

[0020] Such as Figure 1 to Figure 4 As shown, the present invention is a drying device for MC color co-extruded materials, which realizes the drying of plastic strips under tension, avoids insufficient drying caused by mutual connection, and simultaneously realizes the functions of vertical blowing and horizontal spiral blowing. Common hot air drying improves the drying effect and drying efficiency.

[0021] Specifically, if Figure 1 to Figure 4 As shown, including base 1, hot air blower 2, ventilation pipe 3, such as figure 1 As shown, the hot air blower 2 is connected to the base 1, the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com