Fire grate and pyrolysis combined waste incineration equipment

A waste incineration and combined technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of increased combustion aids, increased energy consumption, poor drying effect, etc., to reduce combustion aids, reduce waste Purify energy consumption and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

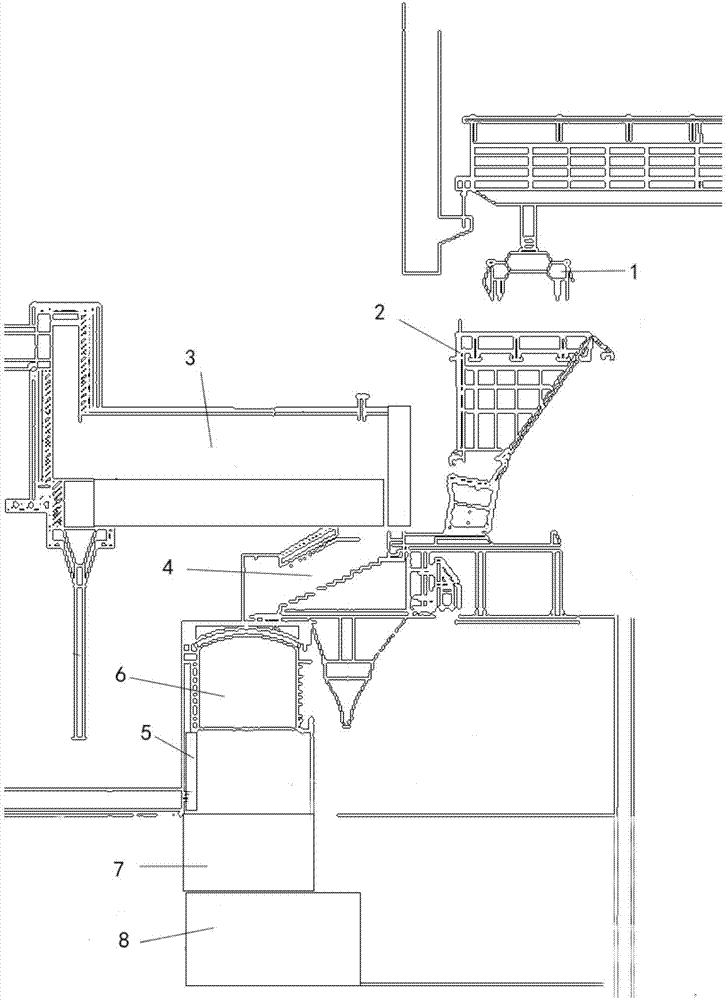

[0016] Such as figure 1 , a grate and pyrolysis combined waste incineration equipment, including gantry crane jaw 1, garbage guide 2, secondary combustion chamber 3, grate furnace 4, circulation pipeline 5, pyrolysis furnace 6, automatic slag discharger 7 , storage box 8; this fire grate and pyrolysis combined waste incineration equipment take pyrolysis furnace 6 as the main body, and fire grate furnace 4 is installed at the feed end of pyrolysis furnace 6, which is inclined; The material end is connected with the garbage guide canister 2, the entrance of the garbage guide canister 2 faces upward, and the gantry crane crane jaw 1 is set above the entrance of the garbage guide canister 2, and the slag outlet of the pyrolysis furnace 6 is connected with the automatic slag discharge machine 7 , the bottom of the automatic slagging machine 7 is provided with a storage box 8, the second combustion chamber 3 is installed on the upper left of the grate furnace 4, and the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com