Feed device for circulating fluidized bed boiler

A technology of circulating fluidized bed and feeding device, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, combustion type, etc., and can solve the problems that garbage easily enters bolts and countersink holes, and garbage is difficult to clean up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

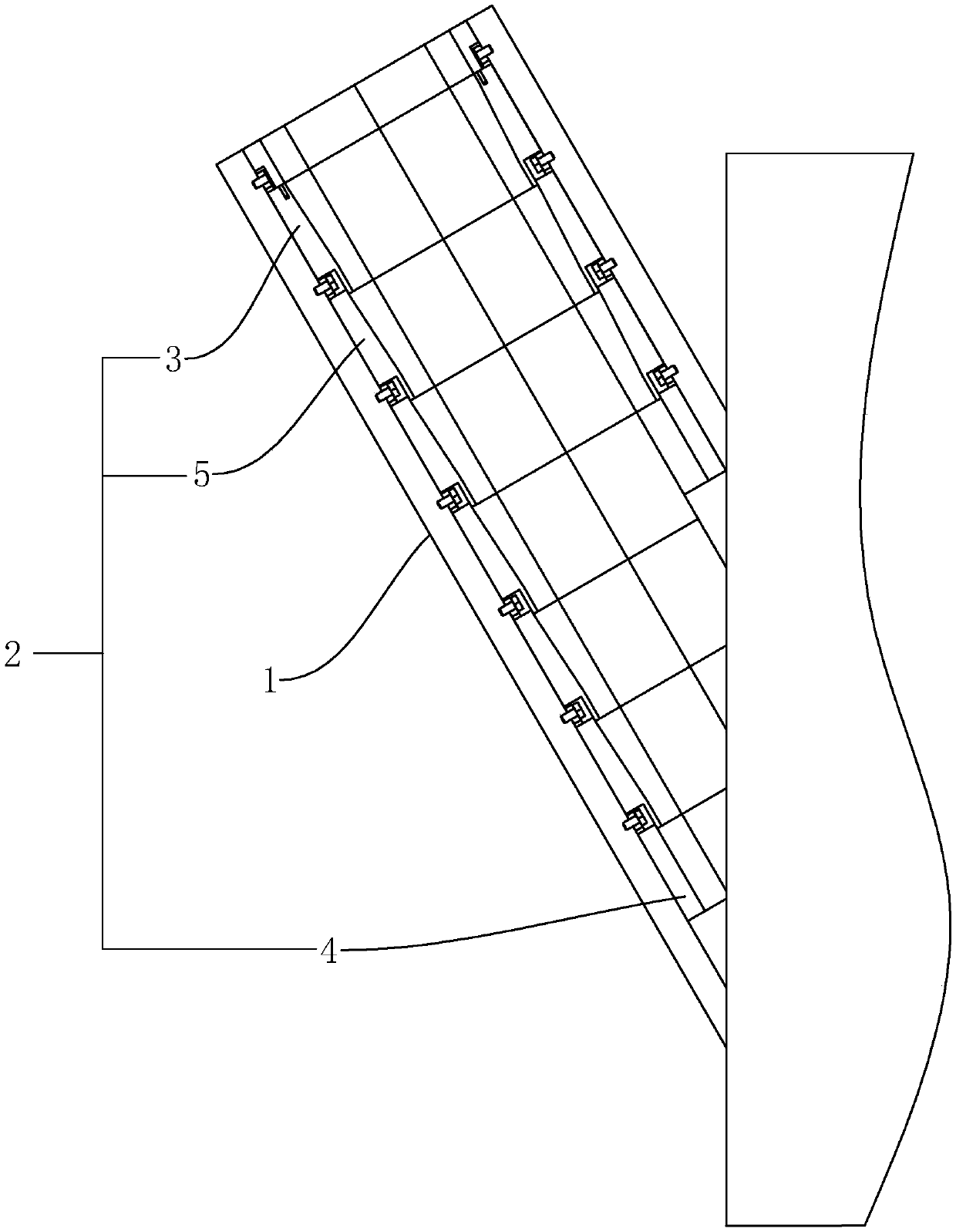

[0033] Such as figure 1 As shown, a feeding device for a circulating fluidized bed boiler includes a concrete drainage pipe 1 at an angle of 63° to the horizontal plane. The interior of the concrete drainage pipe 1 is equipped with multiple rows of steel plate assemblies 2 for guiding materials. The adjacent steel plates A certain gap is left between the components 2 so that the steel plate components 2 can expand freely without extrusion and arching when heated.

[0034] Such as figure 1 As shown, the steel plate assembly 2 includes an inlet fixed steel plate 3 located at the entrance of the concrete drainage pipe 1, an outlet fixed steel plate 4 located at the outlet of the concrete drainage pipe 1, and a middle fixed steel plate 5 covering the position between the inlet fixed steel plate 3 and the outlet fixed steel plate 4.

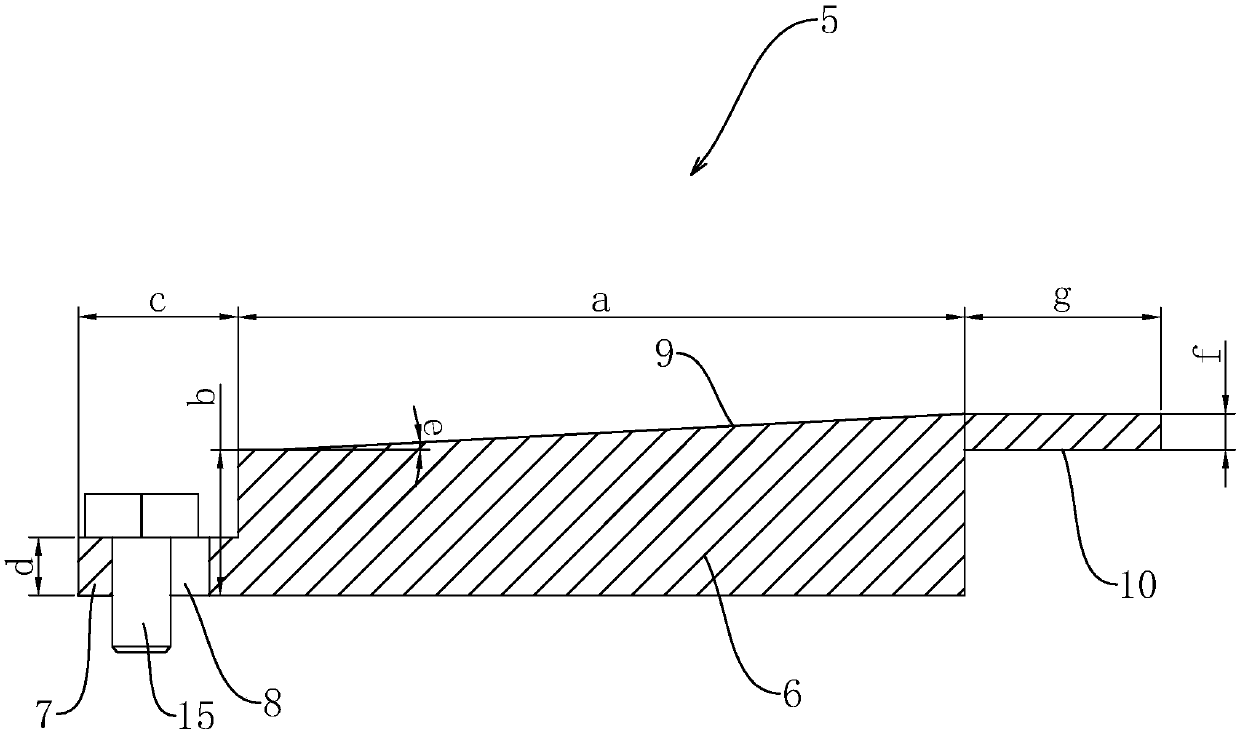

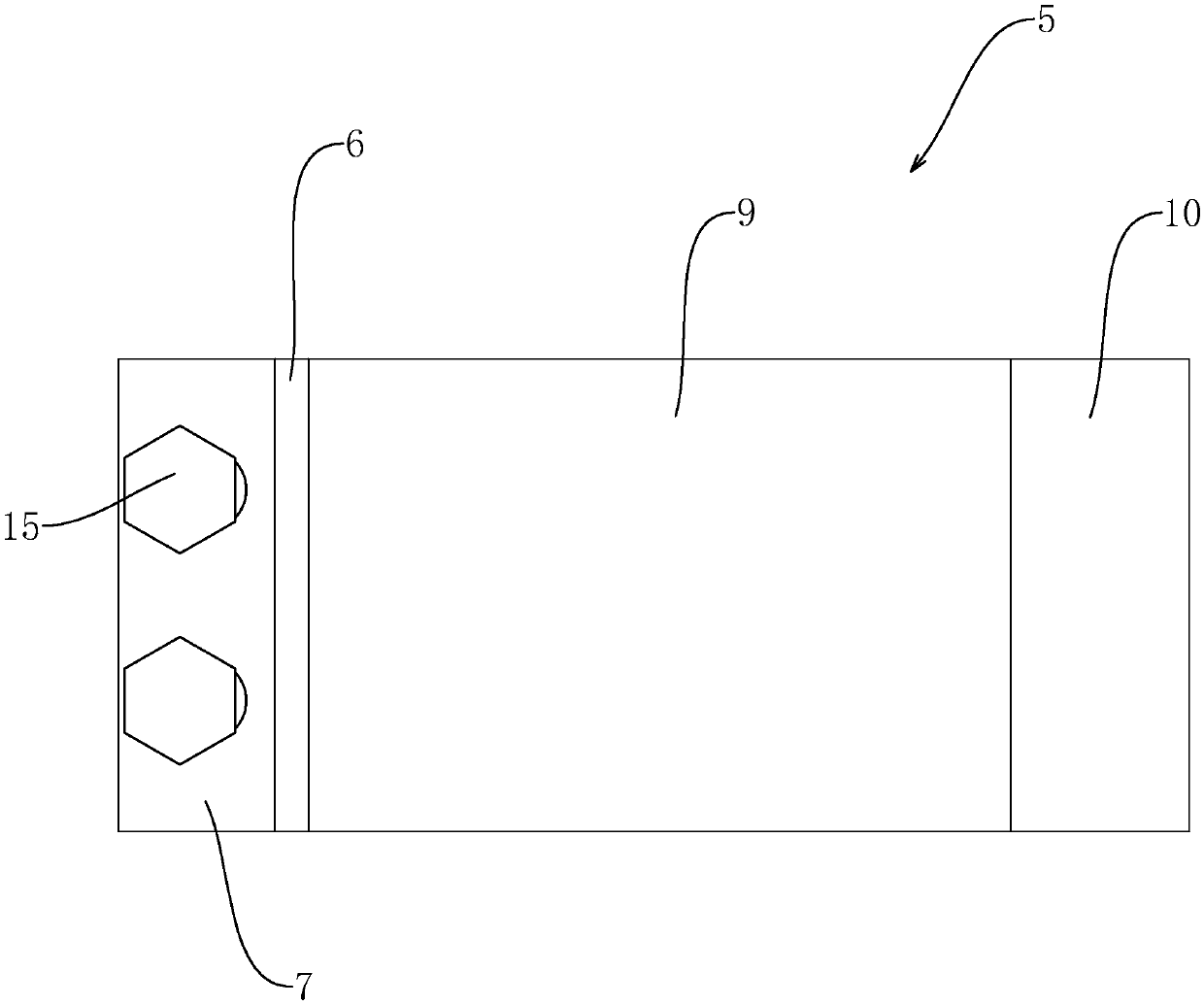

[0035] Such as figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com