Laminated wall body structure and manufacturing method thereof

A wall structure and wall technology, applied in the direction of structural elements, walls, building components, etc., can solve the problems of low strength and poor integrity of the internal connection structure, achieve internal connection structure strength and overall performance enhancement, simple structure, and improved The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

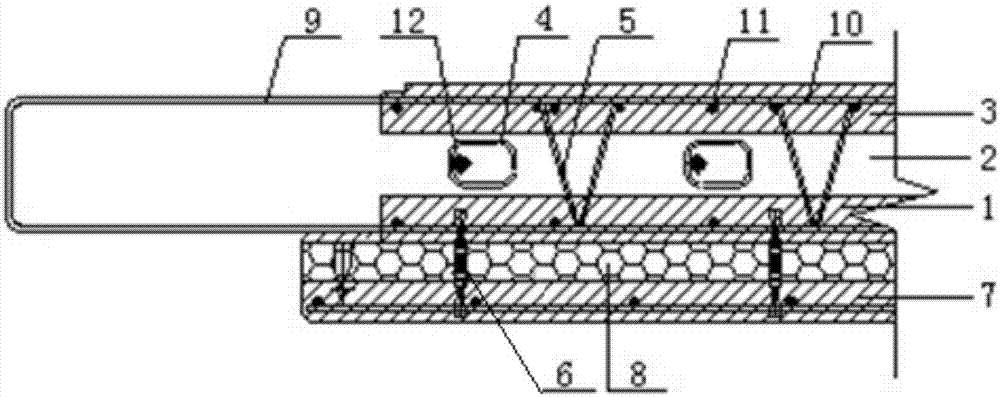

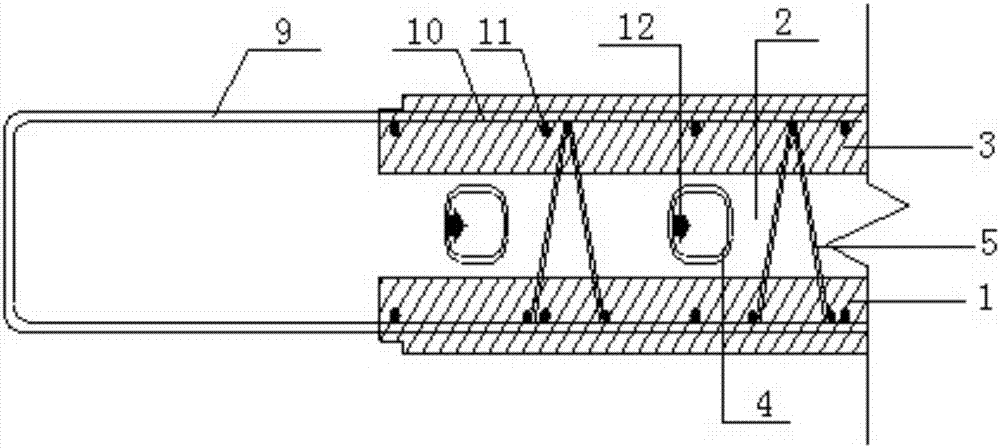

[0033] The laminated wall structure of the present invention comprises prefabricated outer wall panels, a middle cast-in-place layer and a prefabricated inner wall board connected in sequence, the middle cast-in-place layer is provided with vertically connected steel bars, and the vertically connected steel bars are connected with binding rectangular hoops; The vertical connecting steel bars are connected and fixed on the inside of the rectangular hoop; the rectangular hoop is an independent rectangular frame structure, and the plane of the rectangular hoop is perpendicular to the vertical connecting steel bars; there are multiple rectangular hoops, divided into multiple rows, Each row is evenly distributed in the superimposed wall from top to bottom, and the plane of each rectangular hoop is arranged horizontally, and the plane of the rectangular hoop is perpendicular to the vertical plane of the superimposed wall; the prefabricated outer wall panels are prefabricated outer lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com