Method of connecting bridge round pier column with square bent cap anchorage rebar skeleton in sleeving mode

A technology for anchoring steel bars and pier columns, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of high cost, low precision of locators, and inability of secondary use of locators, etc., to achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

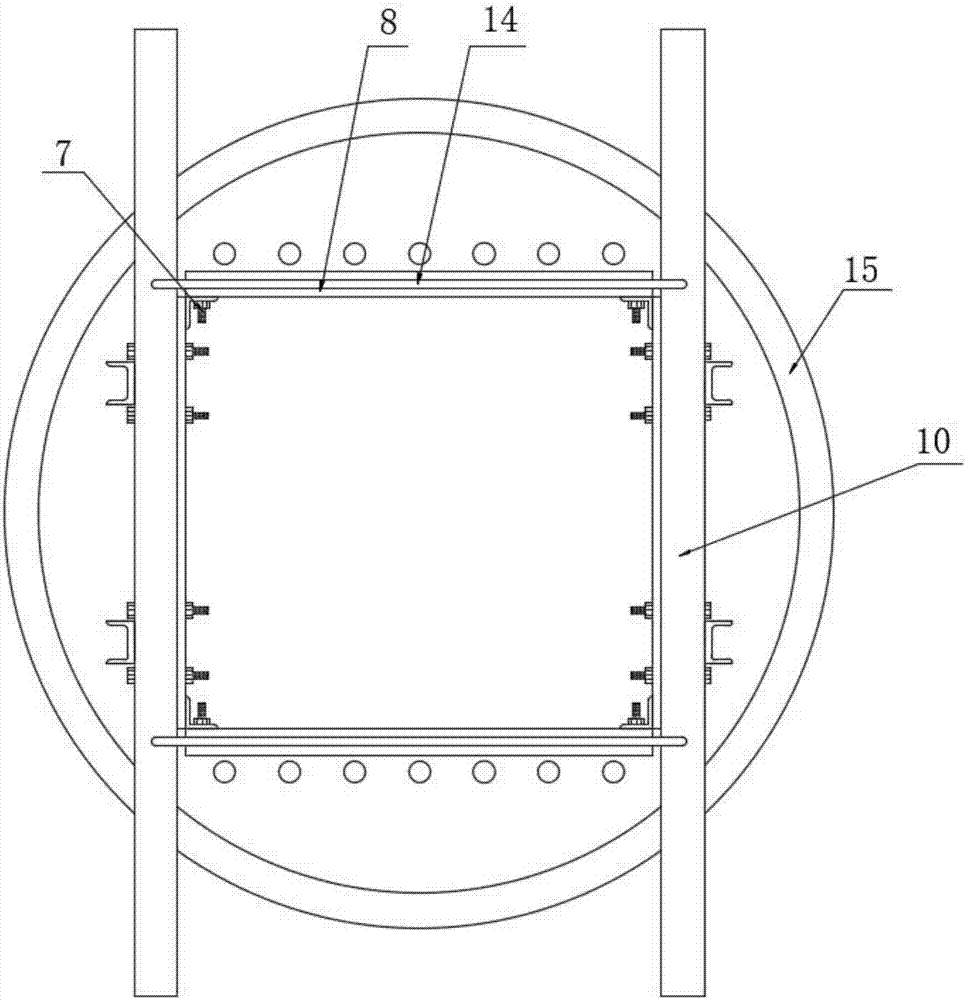

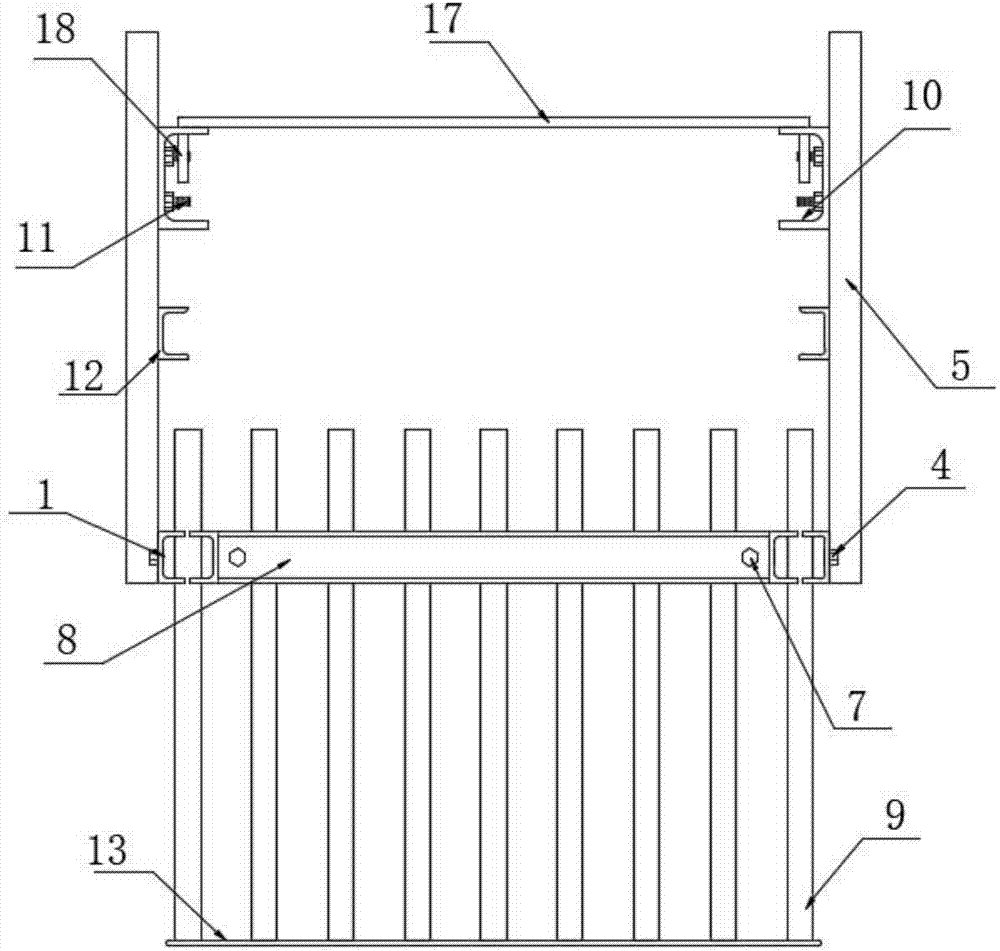

[0032] Such as Figure 1-3 As shown, a fixing device for a square steel bar skeleton includes a pair of oppositely arranged clamping parts 1, and the two ends of the oppositely arranged clamping parts 1 are provided with fixedly connected support parts 8; the clamping parts 1 include internal teeth grooves The steel 2 and the outer tooth channel steel 3, the inner tooth channel steel 2 and the outer tooth channel steel 3 are provided with the corresponding tooth mouth 16, and the teeth on the inner tooth channel steel 2 and the outer tooth channel steel 3 The mouth 16 is arranged oppositely, and the inner tooth channel steel 2 and the outer tooth channel steel 3 are detachably connected through the connecting piece 4. The connecting piece 4 is composed of screws and nuts. The inner toothed channel steel 2 is offset to realize the fastening between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com