Blade manufacturing method and blade

A manufacturing method and technology of blades, which are applied in the manufacture of blades and in the field of blades, and can solve problems such as scrapped blades, cavities in bolt sleeves, and excessive thickness of fiber cloth layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the manufacturing method of the blade of the present invention will be described by taking the embedded bolt sleeve type blade as an example.

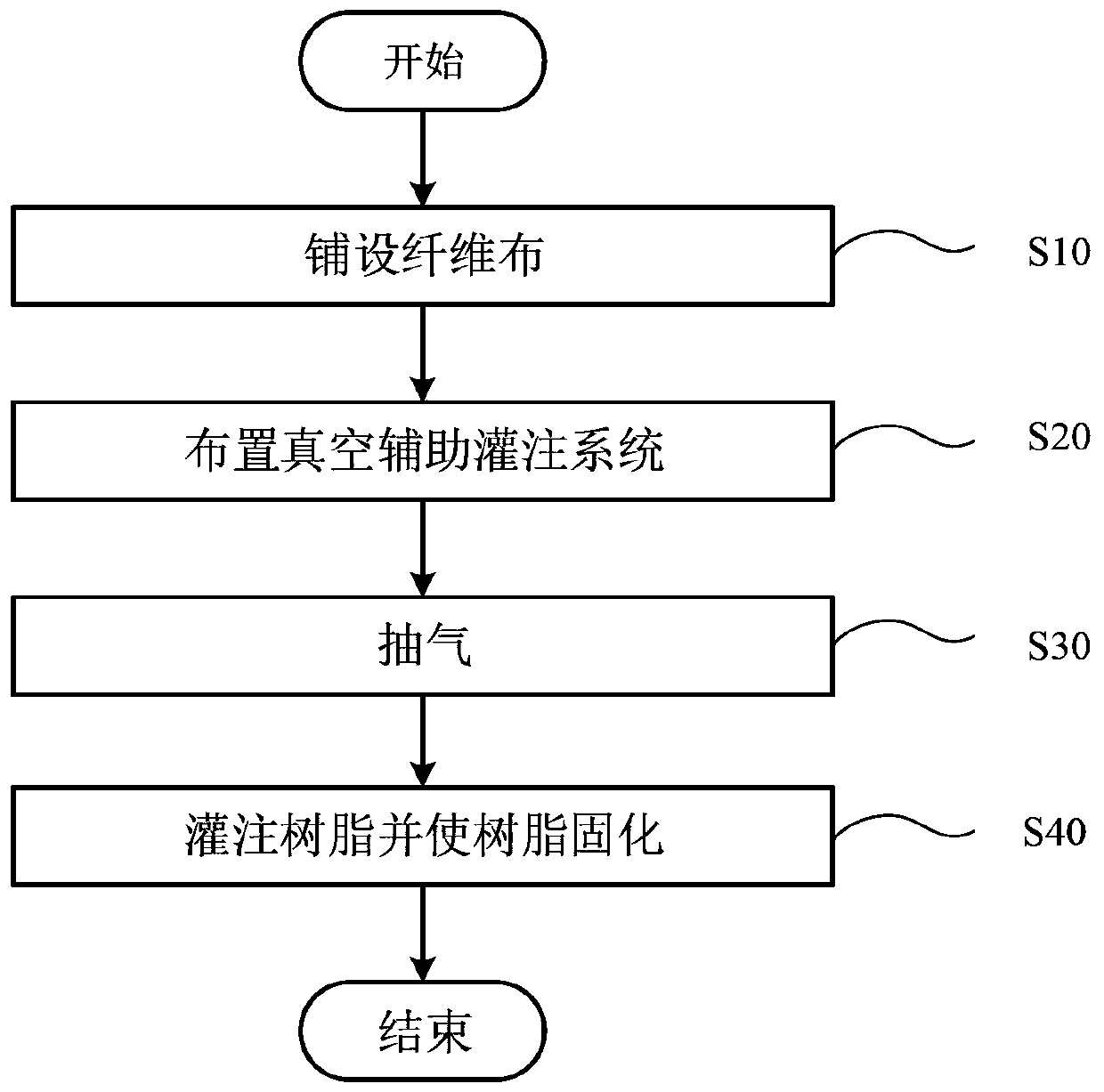

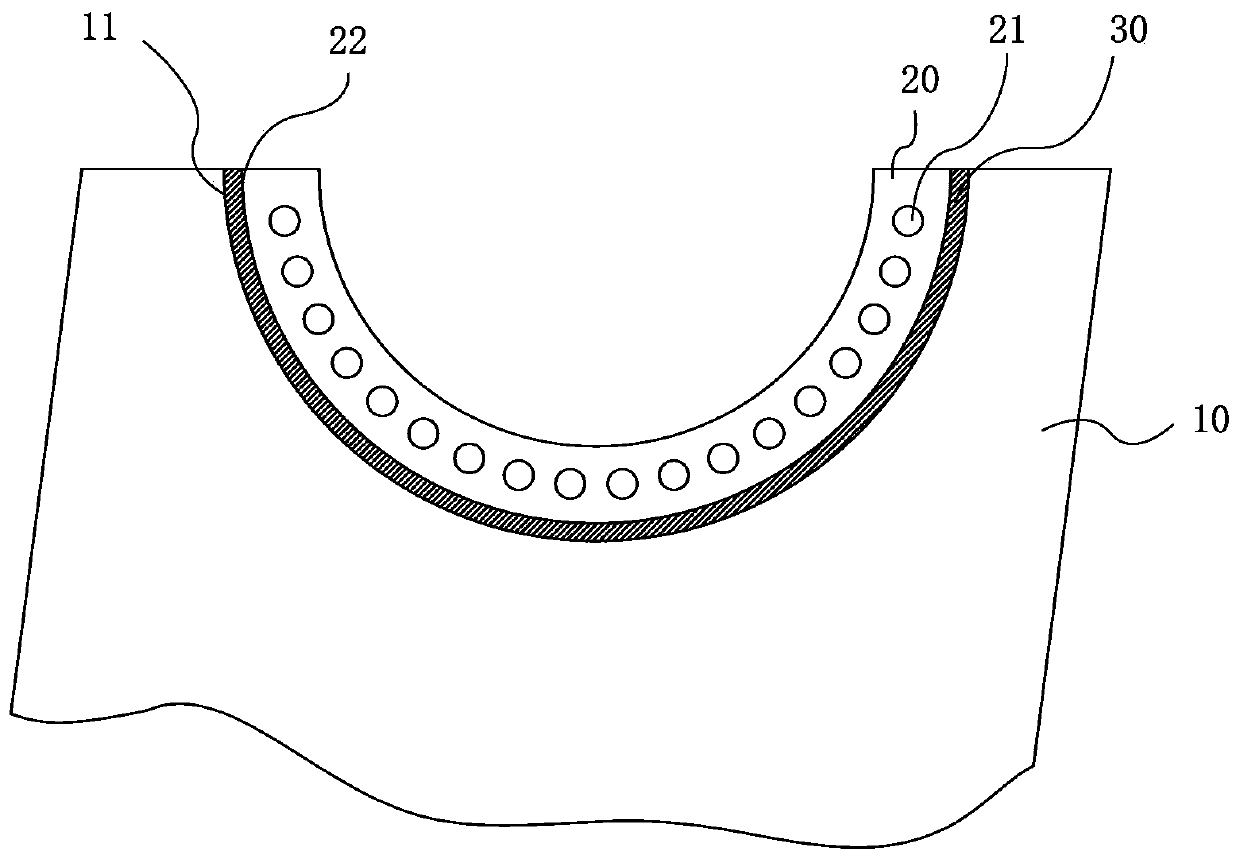

[0028] like Figure 1 to Figure 7 As shown, according to the embodiment of the present invention, the manufacturing method of the blade may include: laying fiber cloth on the blade mold 10; arranging a vacuum infusion system on the fiber cloth, the vacuum infusion system includes a main suction pipe (not shown) and an auxiliary Air extraction pipe 100, wherein, the auxiliary air extraction pipe 100 is arranged at the root of the blade, and the auxiliary air extraction pipe 100 can extract air along the direction D1 from the blade tip towards the blade root (S20); S30); pouring the resin and curing the resin (S40).

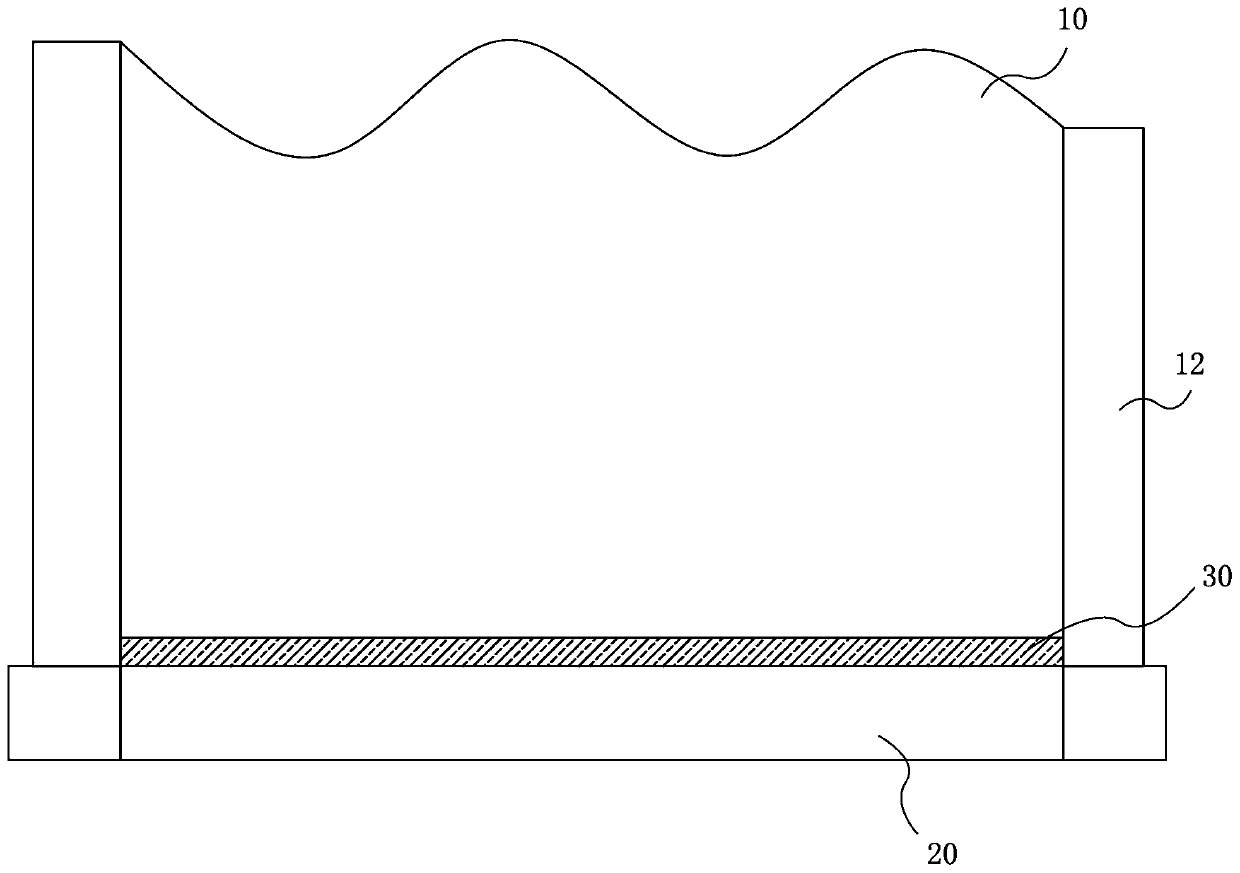

[0029] figure 2 It is a schematic view viewed from the tip of the blade mold 10 toward the root of the blade when manufacturing the blade, image 3 is a plan view of the blade mold 10 seen from the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com