A snap ring type connection baffle installation method

A technology for connecting baffles and installation methods, applied in workpiece clamping devices, metal processing equipment, metal processing and other directions, can solve the problems of the snap ring can not be ejected, the baffle is damaged, etc., and achieve the effect of real-time controllable deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

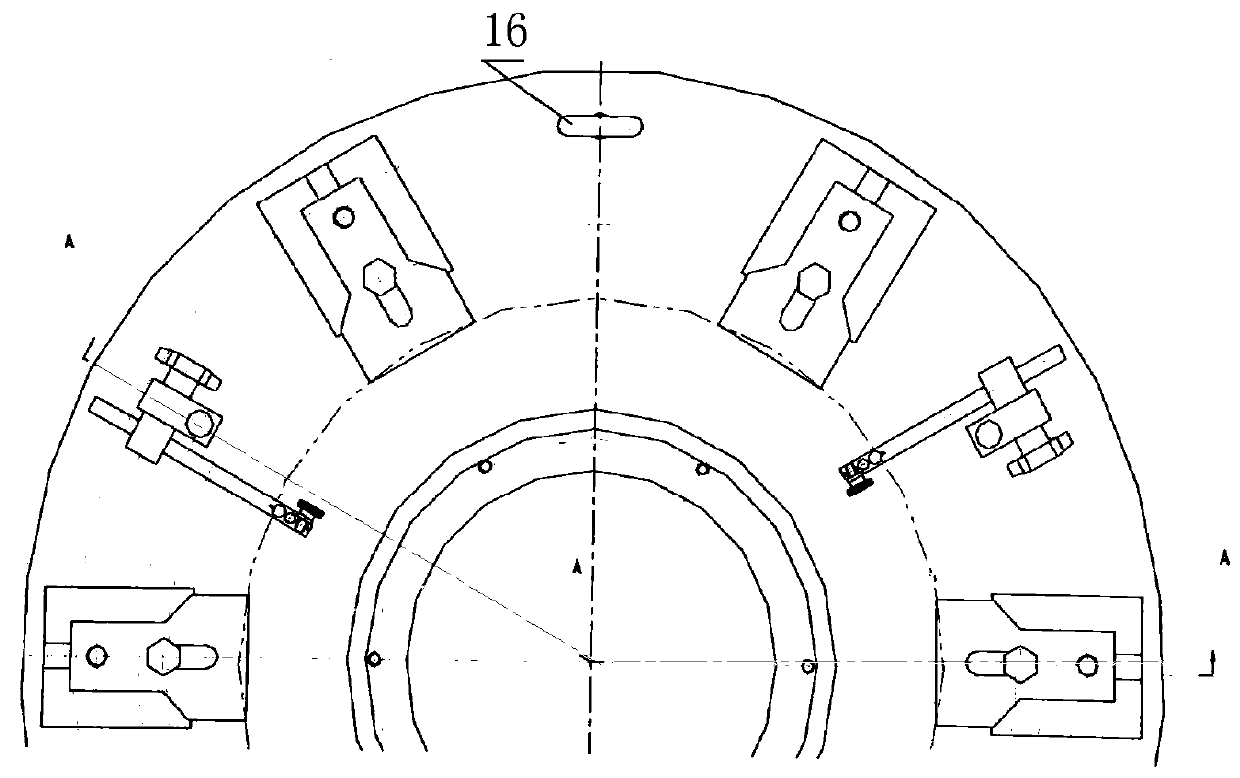

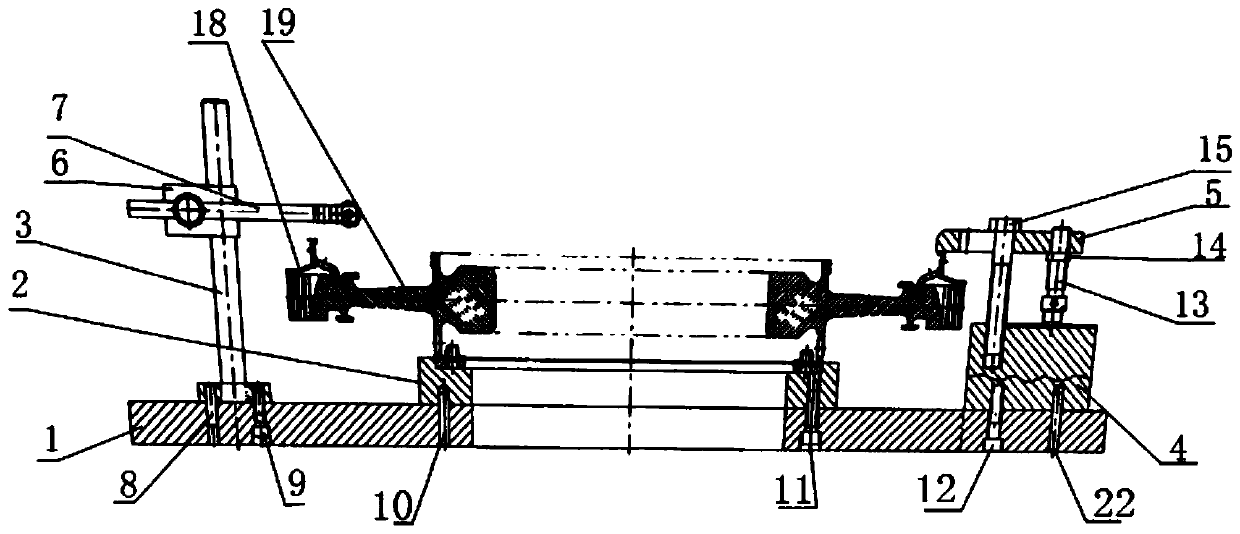

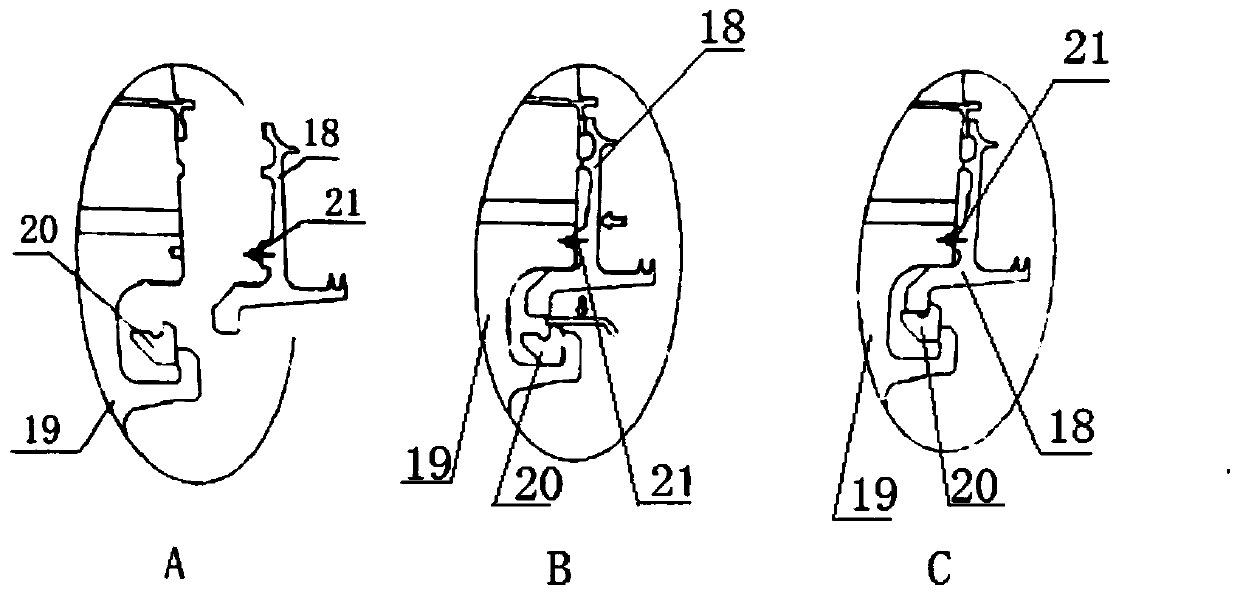

[0023] A snap ring-type installation device for connecting baffles, including a base 1, a positioning ring 2, a support 4, a pressure plate 5 and a watch frame; the base 1 is disc-shaped, and the base 1 is fixed with a pin-8 Set positioning ring 2;

[0024] The table frame includes a table head connector 6, a table rod 7 and a pillar 3, and the pillar 3 is fixed on the base 1 by a pin one 8 and a screw one 9, and the table head joint 6 is fixed on the pillar 3 On, the meter rod 7 is connected with the meter head joint 6, and the dial indicator is installed on the meter head joint 6;

[0025] The support 4 is fixed on the base 1 by screws 3 9 and pins 3 22; the pressure plate 5 is arranged on the support 4, and one end of the pressure plate 5 is provided with an adjustment support 13 parallel to the bolt 15, The adjustment support 13 and the pressure plate 5 are fixed by nuts 14. The pressure plate 5 is evenly distributed on the base 1; shelf.

[0026] The installation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com