Chitosan micromolecular degradation turbulent flow reaction tank

A technology of small molecules and chitosan, applied in the field of reaction tanks, can solve the problems of insufficient mixing, sinking to the bottom of the tank, and low degradation rate of chitosan, and achieve the goal of improving catalytic degradation, promoting catalytic degradation, and increasing degradation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention. In the following detailed description, exemplary embodiments of the present invention are described by way of illustration only. Needless to say, those skilled in the art would realize that the described embodiments can be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims.

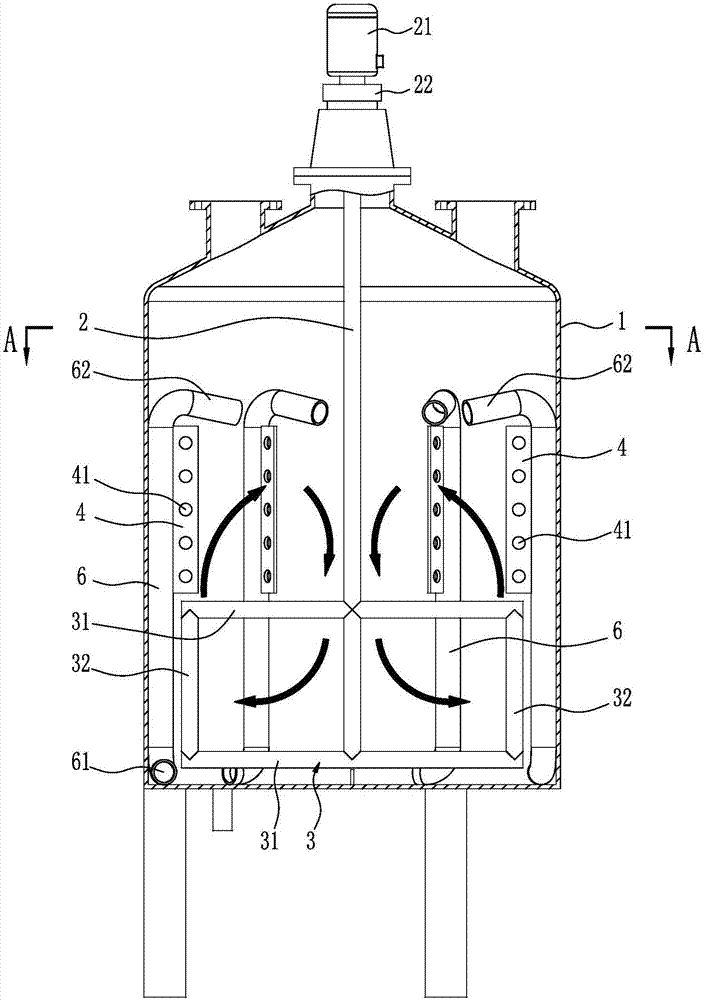

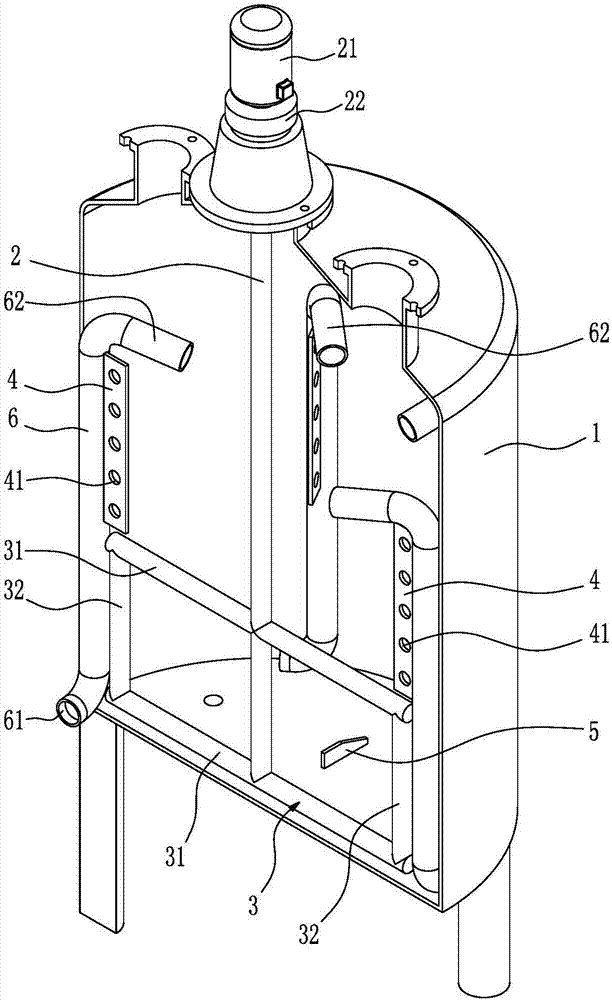

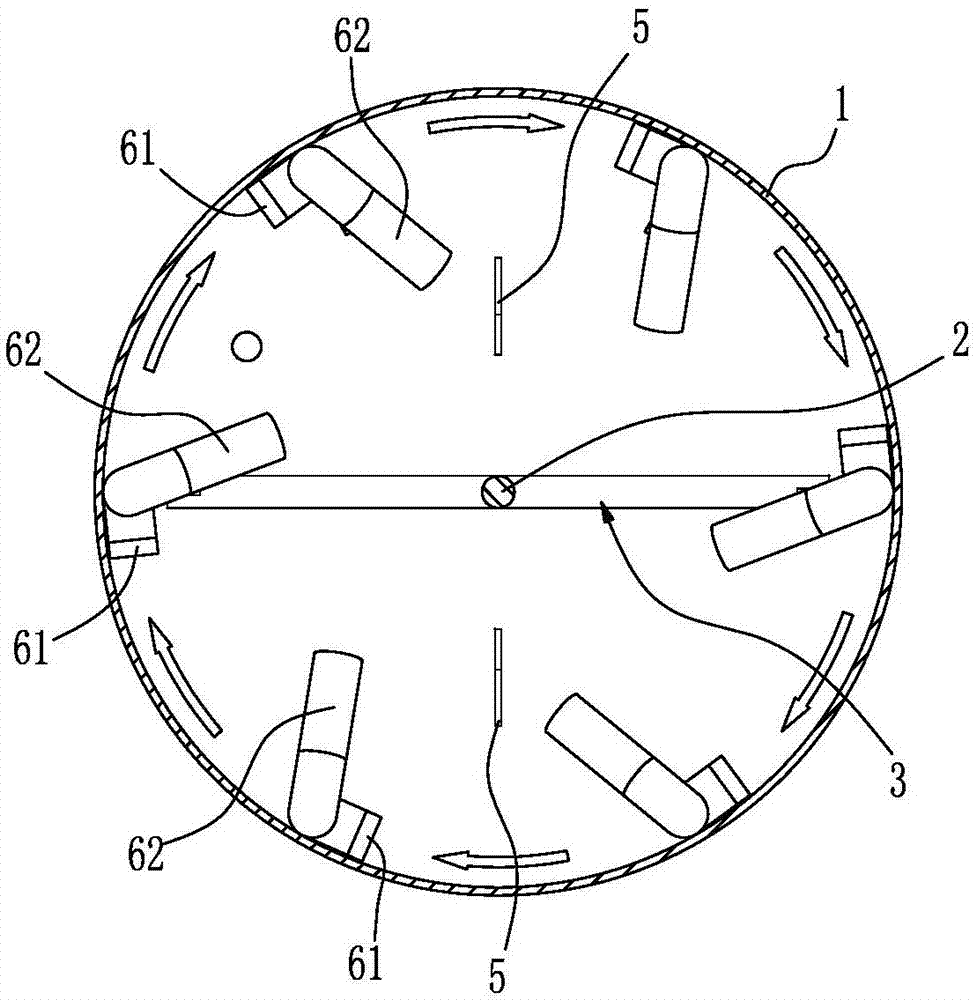

[0018] Such as figure 1 , figure 2 and image 3 As shown, the chitosan small molecule degradation turbulence reaction tank includes a tank body 1 on which a vertically arranged stirring shaft 2 is rotatably installed, and a stirring impeller 3 is provided on the stirring shaft 2 . The stirring impeller 3 in this embodiment includes two stirring bars 31 fixedly arranged radially along the stirring shaft 2, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com