Rotation press switch

A switch and switch module technology, applied in the field of rotary push switches, can solve the problems of external moisture entry, switch damage, and affecting the waterproof effect of the switch, so as to improve the waterproof effect and solve the effect of being easily affected by moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

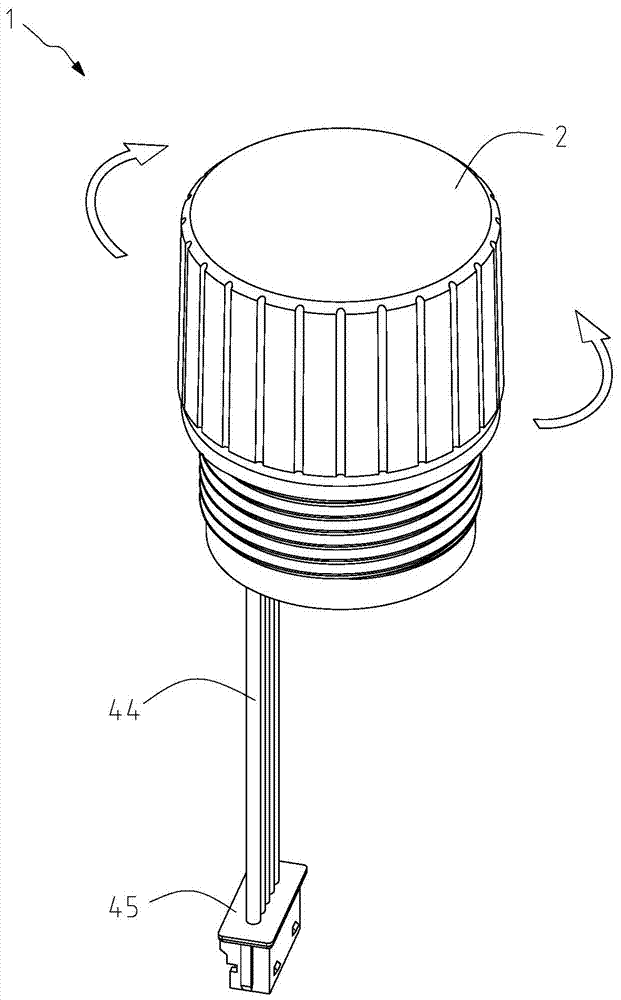

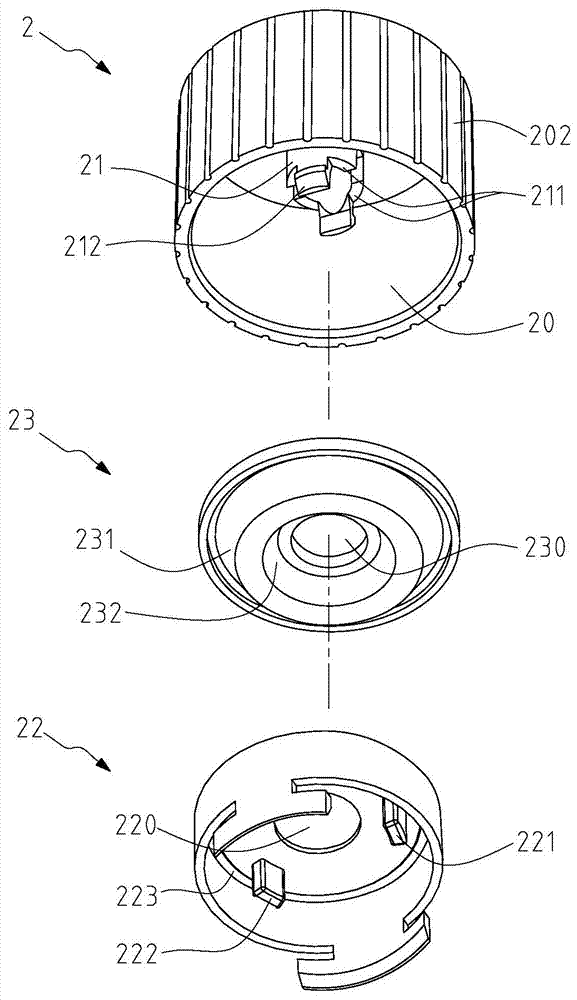

[0068] see Figure 1 to Figure 5 As a preferred embodiment of the rotary press switch of the present invention, the rotary press switch 1 of the present invention includes a cap 2, a seat body 3, a switch module 4, a terminal module 5, a movable seat 6, an elastic component 7 and a contact Terminal 8. The cap 2 has a circular configuration and includes a pressing portion 201 and a wall body 202. The pressing portion 201 and the wall body 202 jointly form an accommodating portion 20 (such as image 3 shown). A connecting column 21 extends downward from the center of the side of the pressing portion 201 facing the accommodating portion 20, one end of which includes an abutting surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com