A device for testing the reliability of baby carriage safety belt and restraint system

A safety belt and reliability technology, which is applied in the field of devices for testing the reliability of the safety belt and restraint system of the stroller, can solve the problems of uncontrollable force accuracy, low data accuracy, unable to guarantee stability, etc., and can protect the pressure sensor. , space saving, simple and clear test principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with example the present invention will be further described. (but not limitation of the invention).

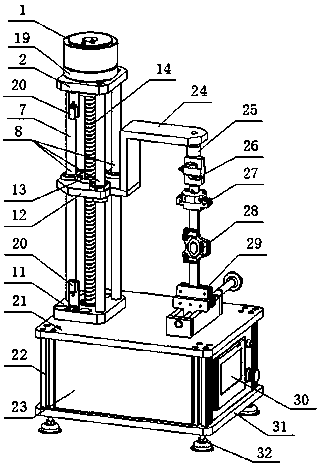

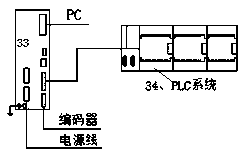

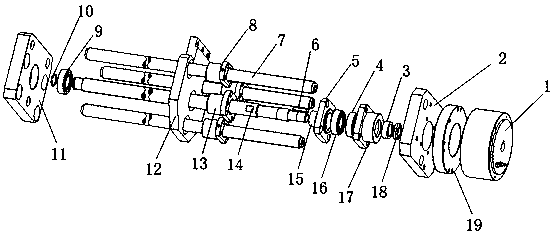

[0010] The test device of the present invention is provided with a direct drive motor (DDR), an upper mounting plate proximity switch, a screw lock washer ring, a back-to-back contact bearing, a bearing gland, a key, a linear bearing guide rod, a linear bearing, a bearing, and an elastic shaft. Retaining ring (snap ring), lower mounting plate, lifting mounting plate, ball nut, ball screw, spacer ring, back-to-back contact bearing two, bearing seat, screw lock nut, motor mounting plate, proximity switch, upper base plate, aluminum Profiles, sheet metal, lifting connecting plate, floating joint, S double hole type pressure sensor (strain gauge sensor), upper quick clamping fixture, seat belt buckle, lower quick clamping fixture, touch screen, lower substrate, floor foot, intelligent drive, PLC system; such as figure 1 As shown, the direct drive mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com