Hot air utilizing device realizing high-efficiency utilization of energy

A technology of energy and hot air, applied in household heating, application, heating fuel, etc., can solve the problem of low heat utilization rate, achieve the effect of optimized and reasonable structural design, and improve recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

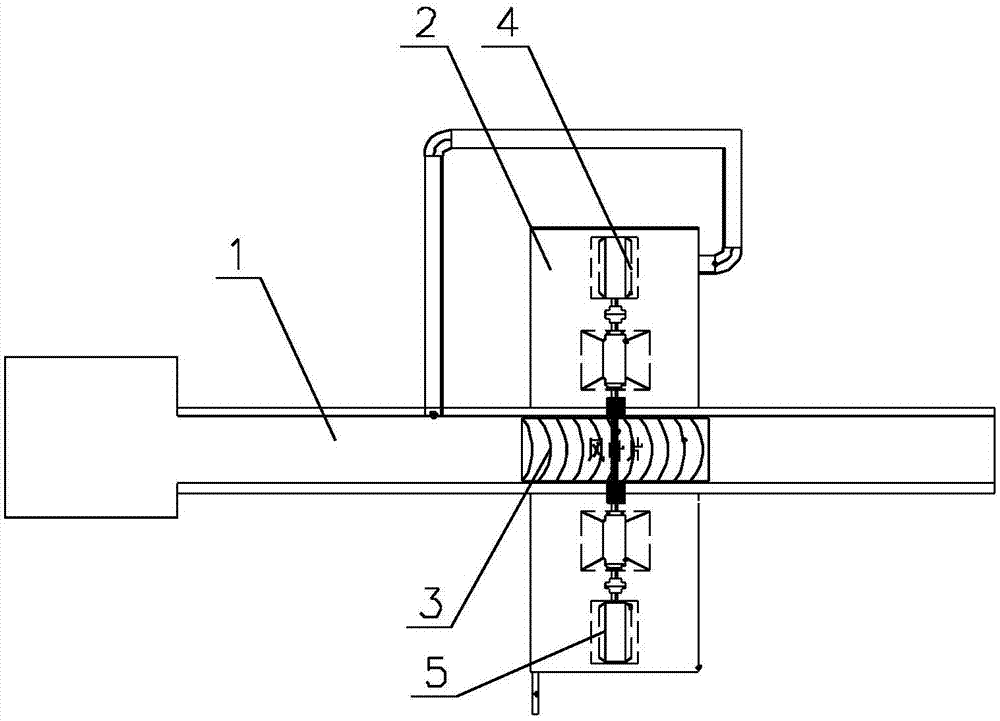

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a hot air utilization device for energy efficient utilization proposed by the present invention.

[0013] refer to figure 1 , a hot air utilization device for efficient energy utilization proposed by the present invention, comprising: a hot air channel 1, an annular energy utilization chamber 2, and a kinetic energy conversion mechanism;

[0014] The two ends of the hot air channel 1 are respectively provided with a hot air inlet and a hot air outlet. The hot air channel 1 includes a gas flow section and a gas utilization section. , the wind moving blade 3 rotates with the flow of hot air in the hot air passage 1;

[0015] The annular energy utilization chamber 2 is sleeved outside the gas utilization section, and the side wall of the annular energy utilization chamber 2 is provided with an air inlet and an air outlet, and the gas outlet communicates with the gas inlet, and the kinetic energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com