Dry-brick rubble wall anti-seismic reinforcement and energy-saving modification integrating method

An energy-saving renovation and wall technology, applied in building construction, building maintenance, construction, etc., can solve the problems of great influence on the appearance of stone masonry walls, damage to the beauty of stone masonry walls, time-consuming and laborious reinforcement work, etc. Improve seismic safety and indoor livability, simple and safe construction methods, and enhance the effect of integrity and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] For further describing the present invention in detail, its specific implementation is as follows:

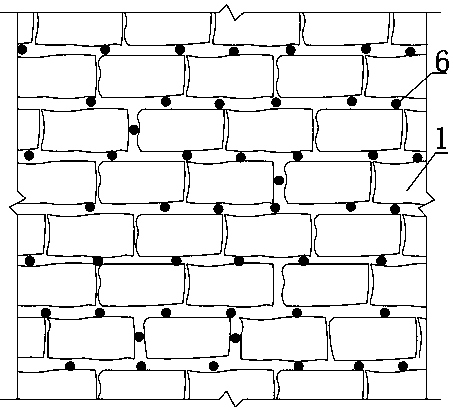

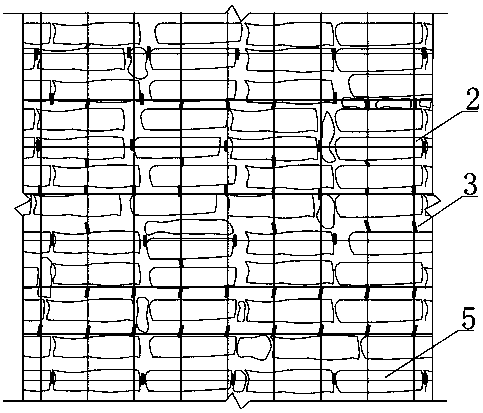

[0026] For the outdoor side wall of the dry-laid rough stone wall, the caulking reinforcement technology is adopted, that is, the structural glue 6 is poured between the gaps of the stones 1, and for the indoor side of the dry-laid rough stone wall, the "L" shaped The steel bar 3 is implanted into the pores of the wall, and the FRP bar grid 2 is suspended and fixed on the extended section of the "L" shaped steel bar 3, and finally, a polymer mortar surface with a thickness of 25mm to 30mm is applied to the interior surface of the existing dry masonry wall Layer 4.

[0027] On the outside of the dry masonry wall body, use a blower to blow off the sand and dust between the gaps of the stone 1, and then inject the structural glue 6 between the gaps of the stone 1.

[0028] On the indoor side of the dry stone wall, use a blower to blow off the sand and dust between the pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com