Cast-in-place pile reinforcement cage module and construction method thereof

A construction method and steel cage technology, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as the deviation of the verticality of the steel cage and affect the overall engineering quality of the pile body, achieve good verticality, and improve on-site installation efficiency , Improve the effect of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

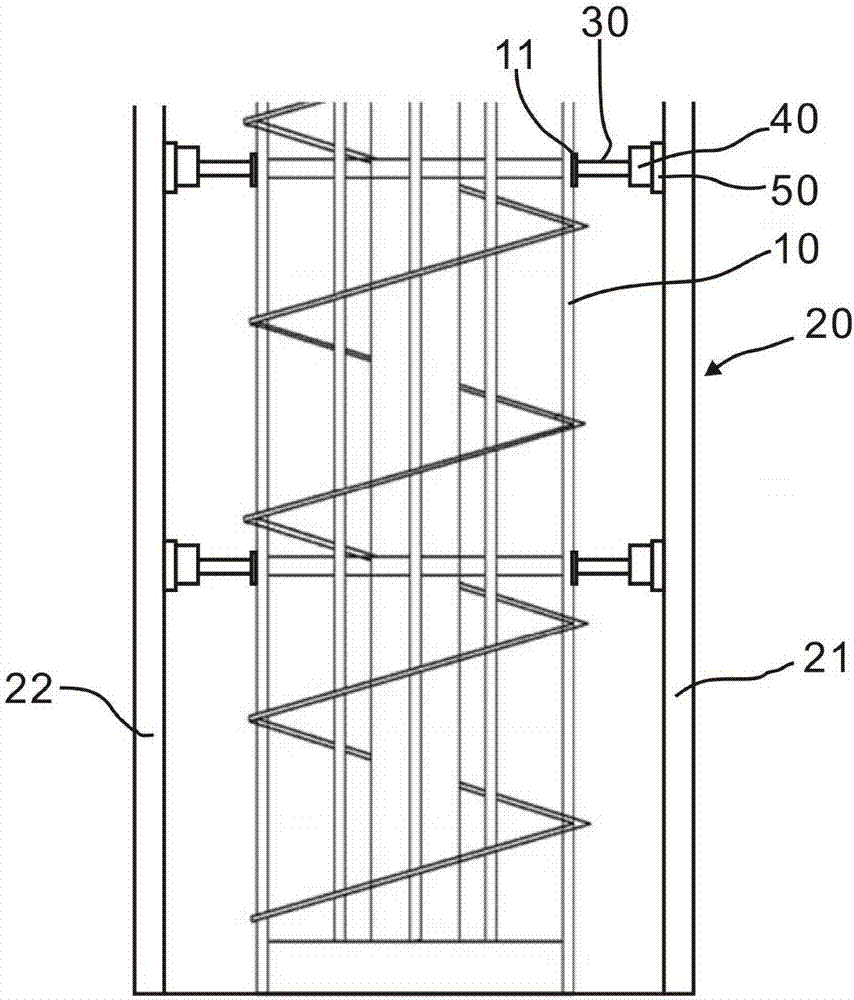

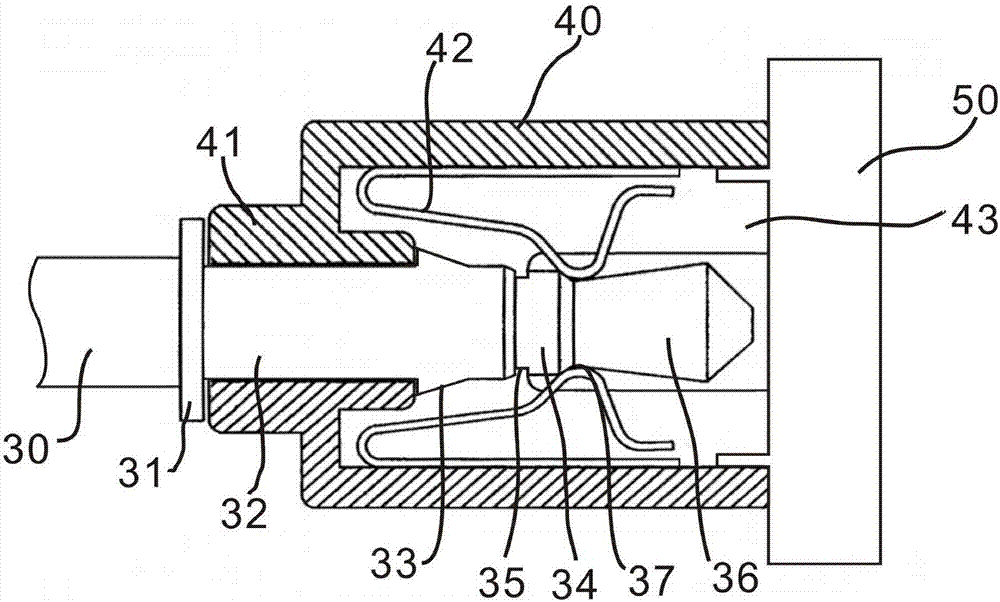

[0029] Such as figure 1 As shown, the present invention provides a reinforced cage assembly for cast-in-situ piles, including a reinforced cage 10 and a casing 20, the casing 20 includes two first casing 21 and a second casing 22 in a semi-circular symmetrical structure, the first casing The cross-section of the tube 21 and the second casing 22 is a semi-circular structure, the first casing 21 and the second casing 22 are detachable or closed structures, when closed, the first casing 21 and the second The casing 22 is a full circular structure.

[0030] The reinforcement cage 10 in the present embodiment comprises main reinforcement and stirrup, and the periphery of main reinforcement is provided with at least two groups of ear reinforcements 11 that are par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com