Lap machine

A technology of a rolling machine and a winding mechanism, which is used in textiles and paper making, etc., can solve the problems of inability to solve the cleaning problem of the suction device, the influence of suction force, and the inability to work, so as to maintain the stability of the equipment, prevent blockage, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

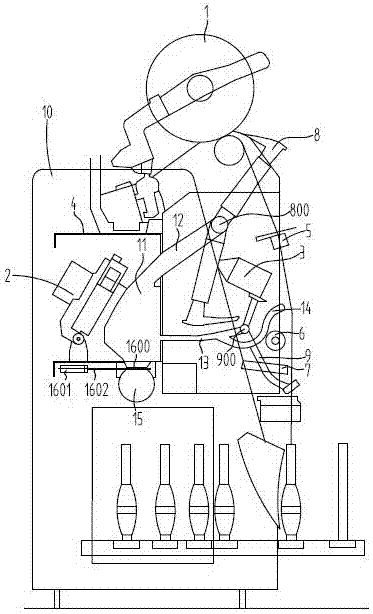

[0012] The present invention will be further described below in conjunction with accompanying drawing.

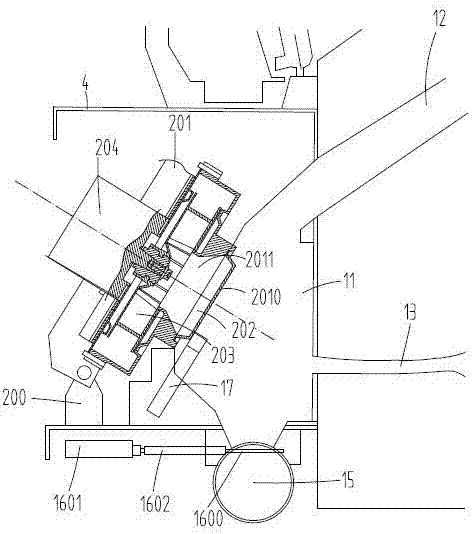

[0013] like figure 1 , 2 As shown, a coiling machine includes a frame 10 on which a winding mechanism 1, a suction device 2, a joint device 3, an auxiliary support 4, a yarn clearer 5, a tension wheel 6, a thread trimmer Device 7, first suction nozzle 8 and second suction nozzle 9. Wherein, the winding mechanism 1 is arranged at the front upper end of the frame 10 , the auxiliary bracket 4 is arranged at the rear side of the frame 10 , and the suction device 2 is arranged in the auxiliary bracket 4 .

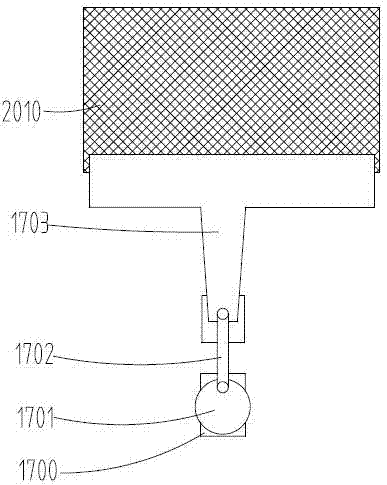

[0014] The suction device 2 includes a mating connection base 200, a housing 201, a filter 202, a bladeless fan 203 and a first motor 204, the connection base 200 is fixedly connected to the auxiliary bracket 4, the housing 201 has a communication The suction port 2010 and the air duct 2011, the housing 201 is hinged with the connecting seat 200, the bladeless fan 203 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com